Big-End Bearings

Inspection / Reassembly

A5.05. 02.04.02.00

M20

en / 07.01.2000 IB001357 3/4

02

Ĺ

3. Tightening the big-end bolts.

3.1 Measuring the gap (02.04.01.nn,

sequence of operations 1) is only

required if new shells are fitted or the

gap was not measured on

disaassembly.

3.2 Tighten the lower bolts 3 and 4 with a

torque

M = 160 Nm.

3.3 Tighten upper bolts 1 and 2 twice in the

sequence 1 - 2 - 1 - 2 with a torque

M = 160 Nm.

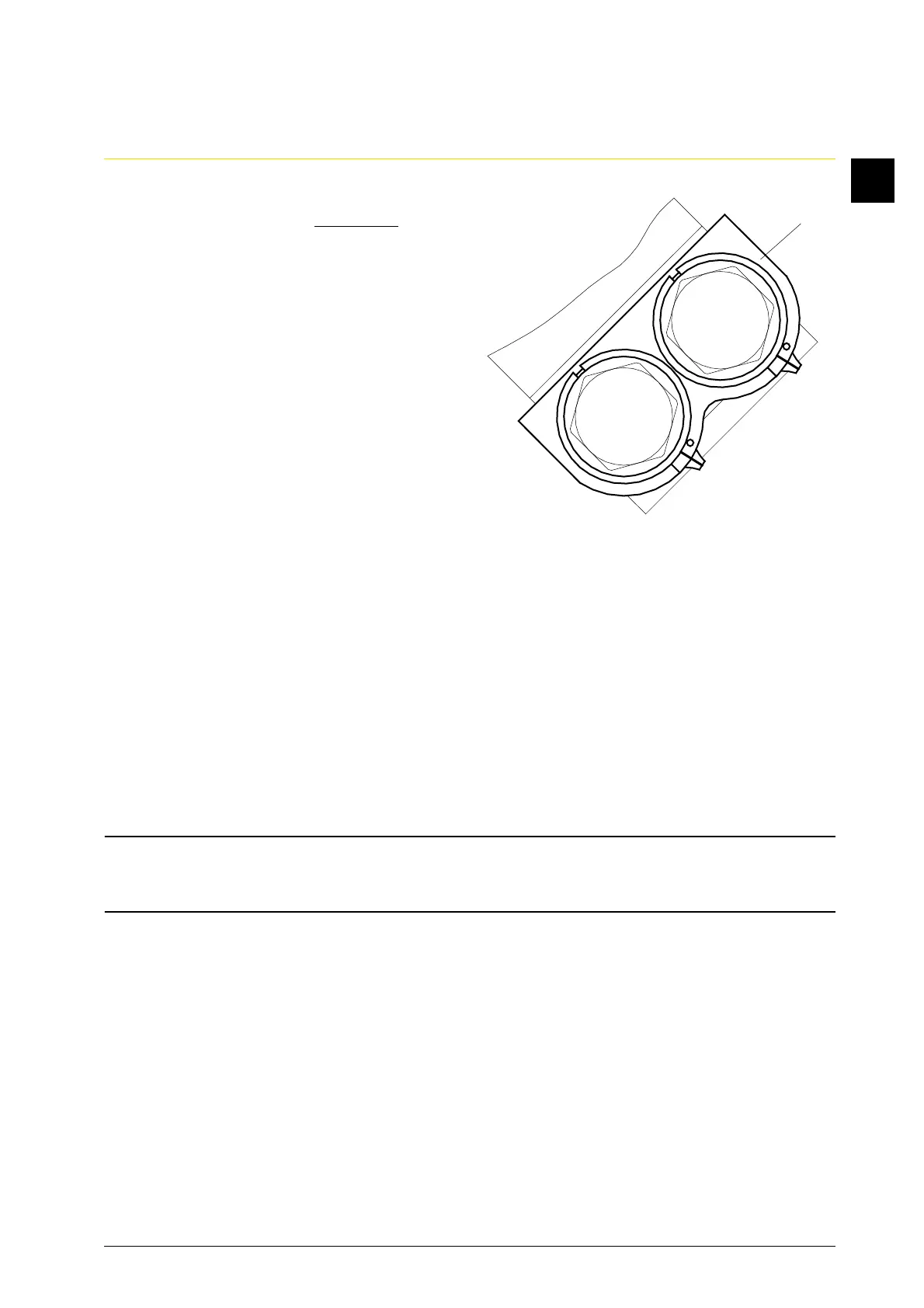

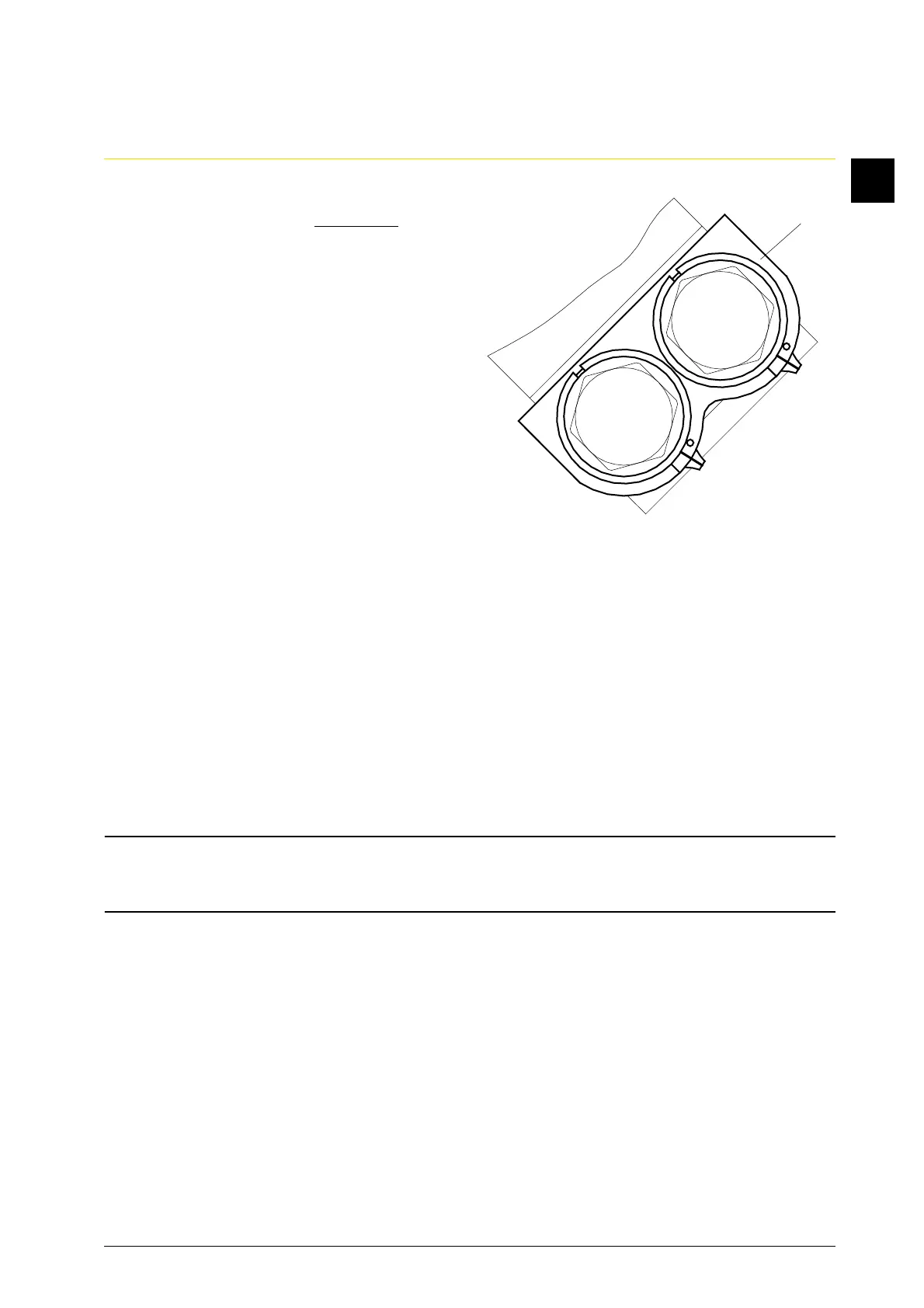

3.4 For checking the tightening operation, place the angle gages (Fig. 3/W3) over the bolt head

collars according to the marking and pull the pointer against the stop.

Check the set collars of the gage for freedom. Mark the position of the bolts if you have no

tightening angle gage (tightening angle gages for big-end bolts 3 and 4 shown).

3.5 Tighten the lower bolts 3, 4 with a torque

M = 350 Nm.

3.6 Tighten the upper bolts 1, 2 with a torque

M = 350 Nm.

Achtung:

After tightening big-end bolts 1 and 2 up to a final torque of 350 Nm, tighten bolts 3 and 4

again with the final torque of 350 Nm to avoid a loss of pretension by settling.

Fig. 3

W3

34

Loading...

Loading...