Inlet Valve Cones

Repair / Checking

A5.05. 01.08.01.01

M20

en / 12.10.2000 IB022652 4/5

01

Ĺ

4. Maintenance (check of contact

reflection/grinding)

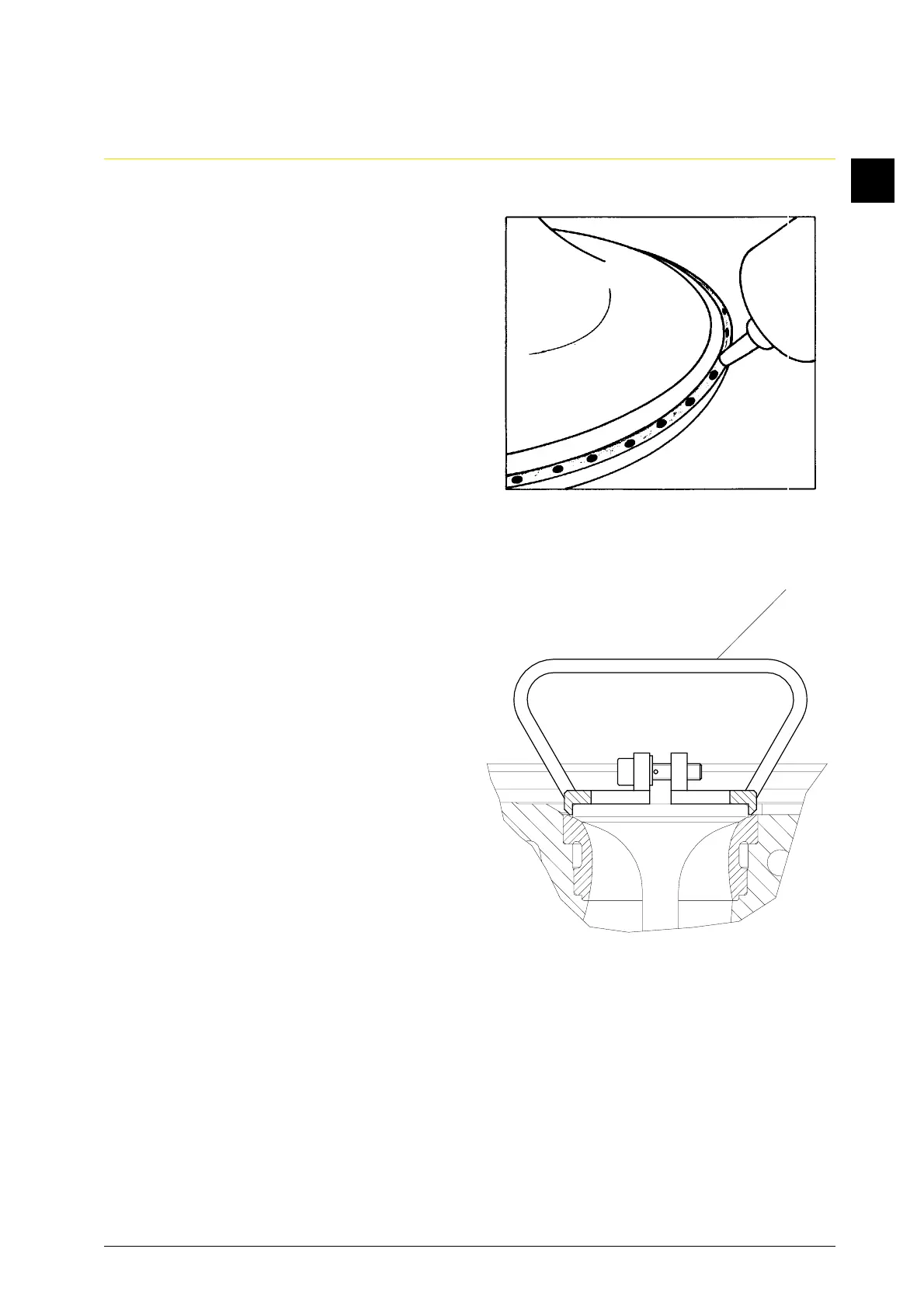

4.1 Apply small dots of the diamond paste

Dp 30/10 - 15 µm with a syringe to the

valve seat of the new or refinished

valve cone and distribute the paste

uniformly (Fig. 4). Therafter the seat

ring surface is to be sprayed with a

thinner (F25) belonging to the diamond

paste, for dilution and in order to

increase of the grip.

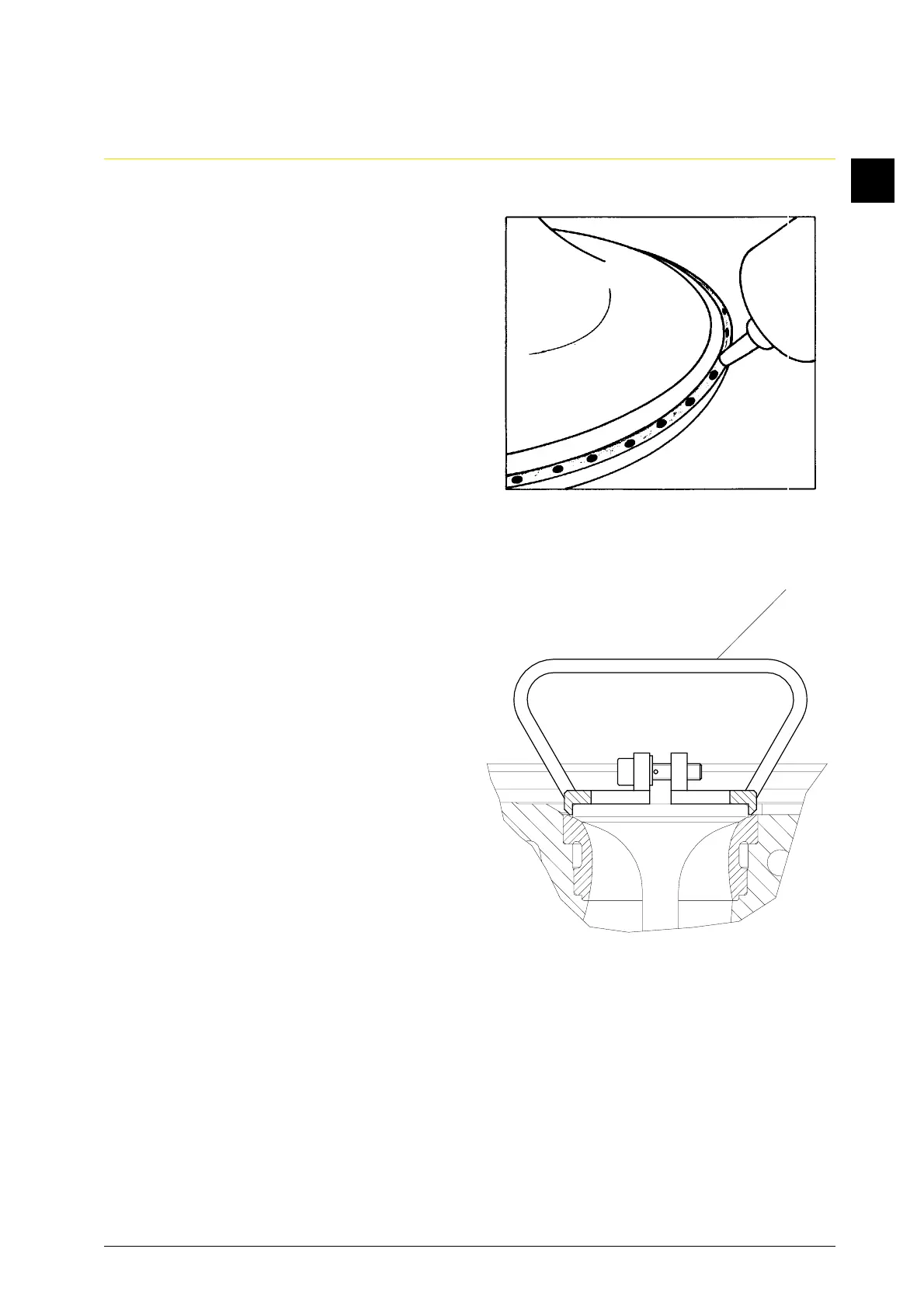

4.2 Insert the oiled valve stem into the

guide bush. Fasten the device (Fig. 5/

W1) to the valve head and grind the

valve cone face and seat by hand

applying a moderate pressure, rotating

the device. The contact reflection “a”

(Fig. 6/a), visible by the rough grinding

process, should be

30 - 50 % of the circumferential seat

width “b”

starting from the outside diameter.

Fig. 4

W1

Fig. 5

Loading...

Loading...