Big-End Bearings

Inspection / Reassembly

A5.05. 02.04.02.00

M20

en / 07.01.2000 IB001357 1/4

02

Ĺ

See also: 02.04.01.nn

Spare parts list: B1.05.02.2.2601

Time requirement: 1 Pers./ 0,50 h

Personnel qualification: Chief engineer, skilled engine hand

---------------------------------------------------------------------------------------------------------------------

Operating medium: Heavy fuel and distillate fuel

Tools:

Torque wrench 60 - 420 Nm 3/4" W1 * 1.9454-60

Clamp W2 2.9125-A

Tightening angle gage W3 2.9180-A

Turning rod W4 * 2.9100-380

* not available as figure

Auxiliary material:

Molykote paste “G-Rapid Plus” **

** or a product of equal standard

Note:

The bearing caps, shells and bolts have been marked according to their cylinder numbers

and must not be interchanged. New parts are to be marked accordingly. Lubricant for

threads and bolt contact surfaces Molykote paste “G-Rapid Plus”.

Sequence of operations:

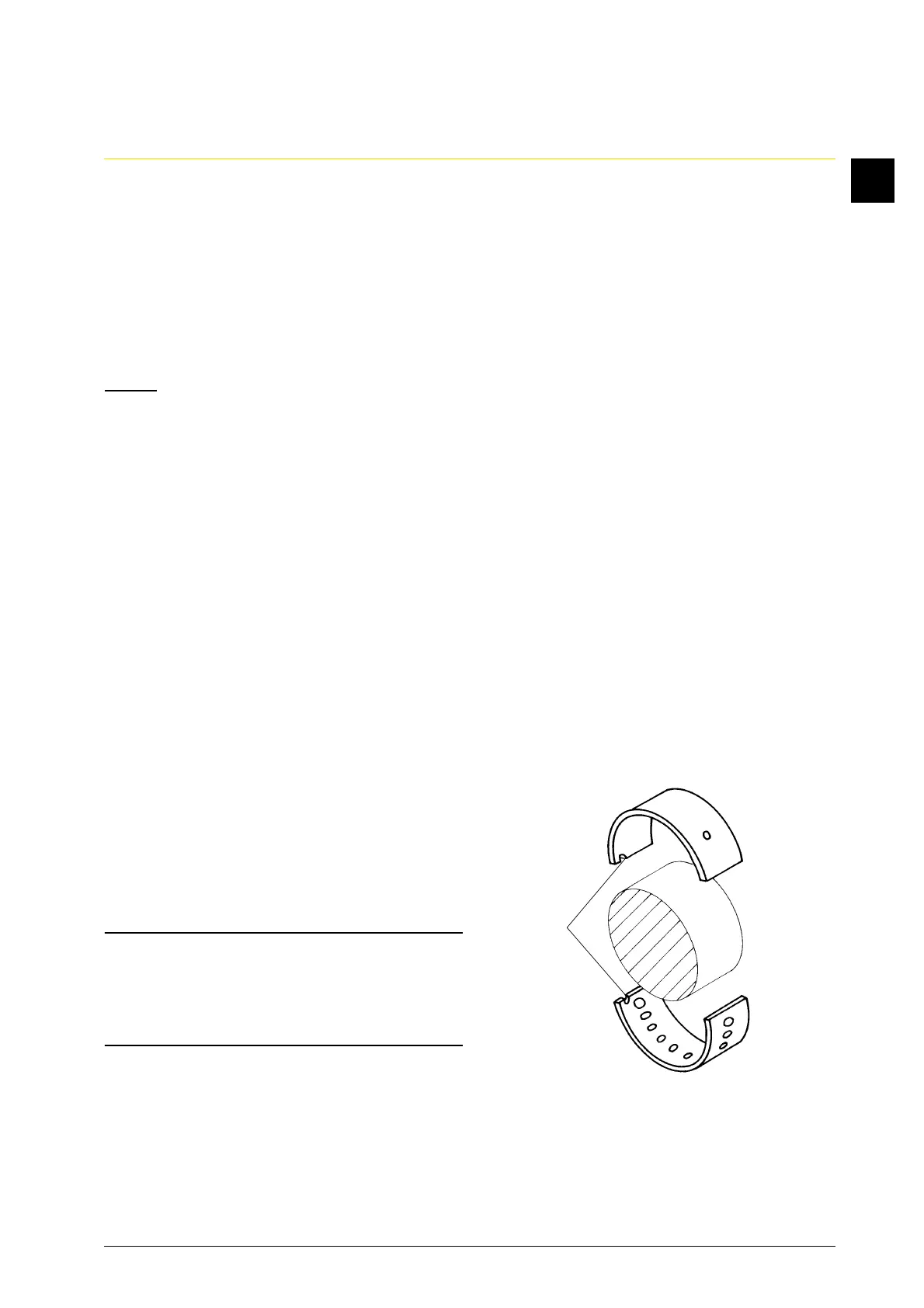

1. Fitting the bearing shells

1.1 Clean and oil the crankpin.

1.2 Oil the inside and outside of the bearing

shells and put them on the crankpin.

Attention:

Hole (Fig. 1/X) for the fixation of the

bearing shells at the face of the bottom

and top shell of the shell half pointing

to the clutch side.

X

Fig. 1

Loading...

Loading...