Big-End Bearings

Inspection / Reassembly

A5.05. 02.04.02.00

M20

en / 07.01.2000 IB001357 2/4

02

Ĺ

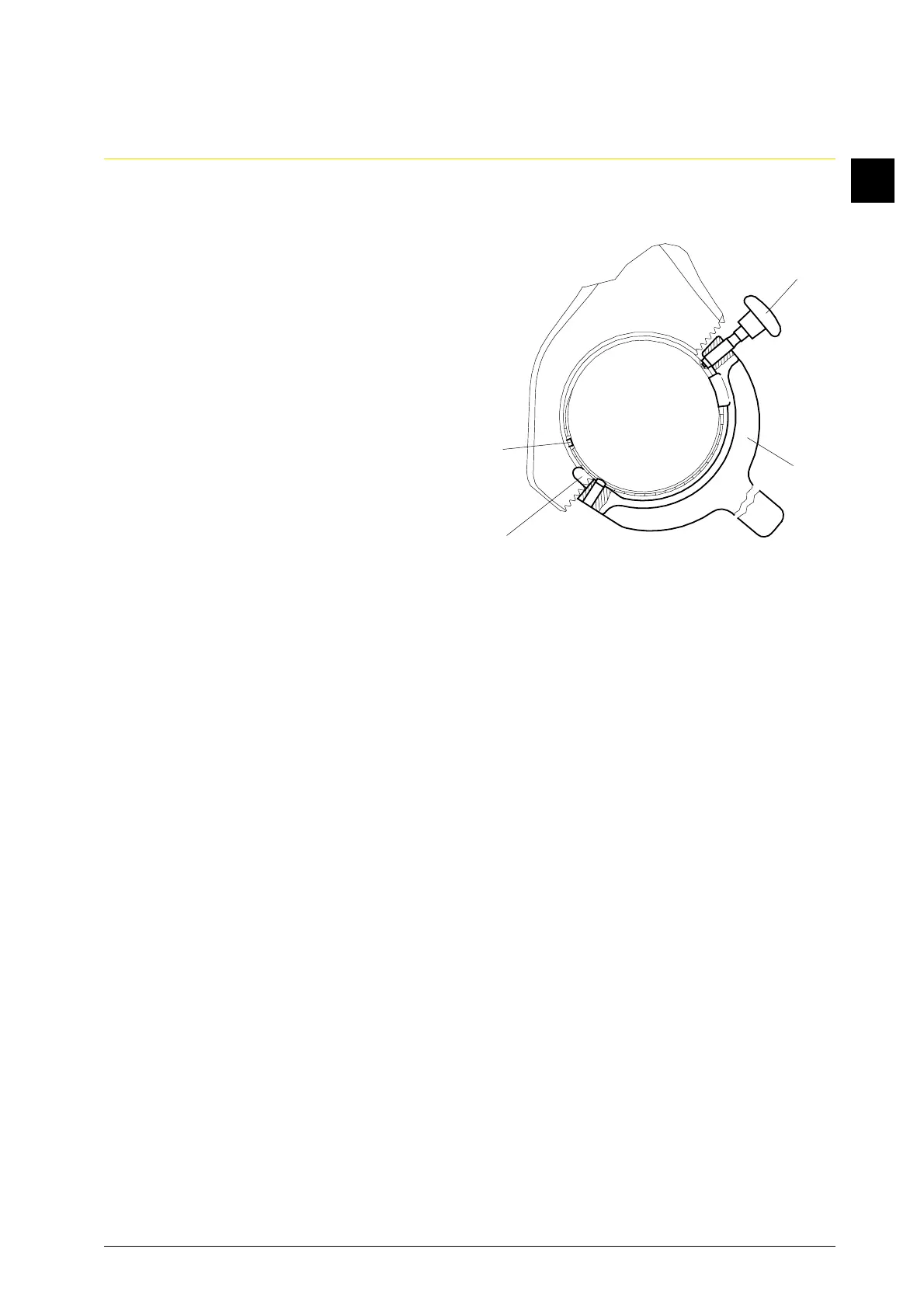

1.3 Hold the bearing shells in this position

and shift the clamp (Fig. 2/W2) over the

shells so that the lower dog of the

clamp engages in the oil hole of the

bottom shell. The dog of the screw

(Fig. 2/1) engages in the hole of the top

shell. Slightly tighten the screw of the

clamp.

1.4 Let the clamp rest against the top joint

face of the big end and turn the

crankshaft until the big end lightly rests

on the bearing shells.

Note:

Lug (Fig. 2/2) of the clamp engages in

the groove of the joint face for centrical

guide of the bearing shells of big-end

bearing (4).

1.5 Turn the bearing shells with the handle

of the clamp so that the dowel pin (3) in

the big-end bore engages in the hole of

the bearing shells and that the shells

have good contact in the big-end bore.

The bearing shells might get damaged

if the reassembly is incorrect.

1.6 Move the piston to TDC. remove clamp

and piston suspension device.

2. Fitting the bearing cap.

2.1 Bring bearing cap into a convenient

position and hold against the

connecting-rod big end. Lubricate

threads and contact faces of the bolt

heads with Molykote paste “G-Rapid

Plus” exclusively. Screw in the bolts.

Fig. 2

3

2

1

W2

Loading...

Loading...