RPM Switch

Inspection / Adjust

A5.05. 11.05.01.01

7500

M20/M25/M32/M453C/M552C

en / 31.05.2000 IB021724 1/2

11

Ĺ

See also:

Spare parts list:

Time requirement: 1 Pers./ 1,00 h

Personnel qualification: E-specialist

---------------------------------------------------------------------------------------------------------------------

Operating medium: Heavy fuel and distillate fuel

Inspection:

Check the function of the rpm switches every 7,500 operating hours.

Note:

The engine speed must be constant whilst testing.

Sequence of operations:

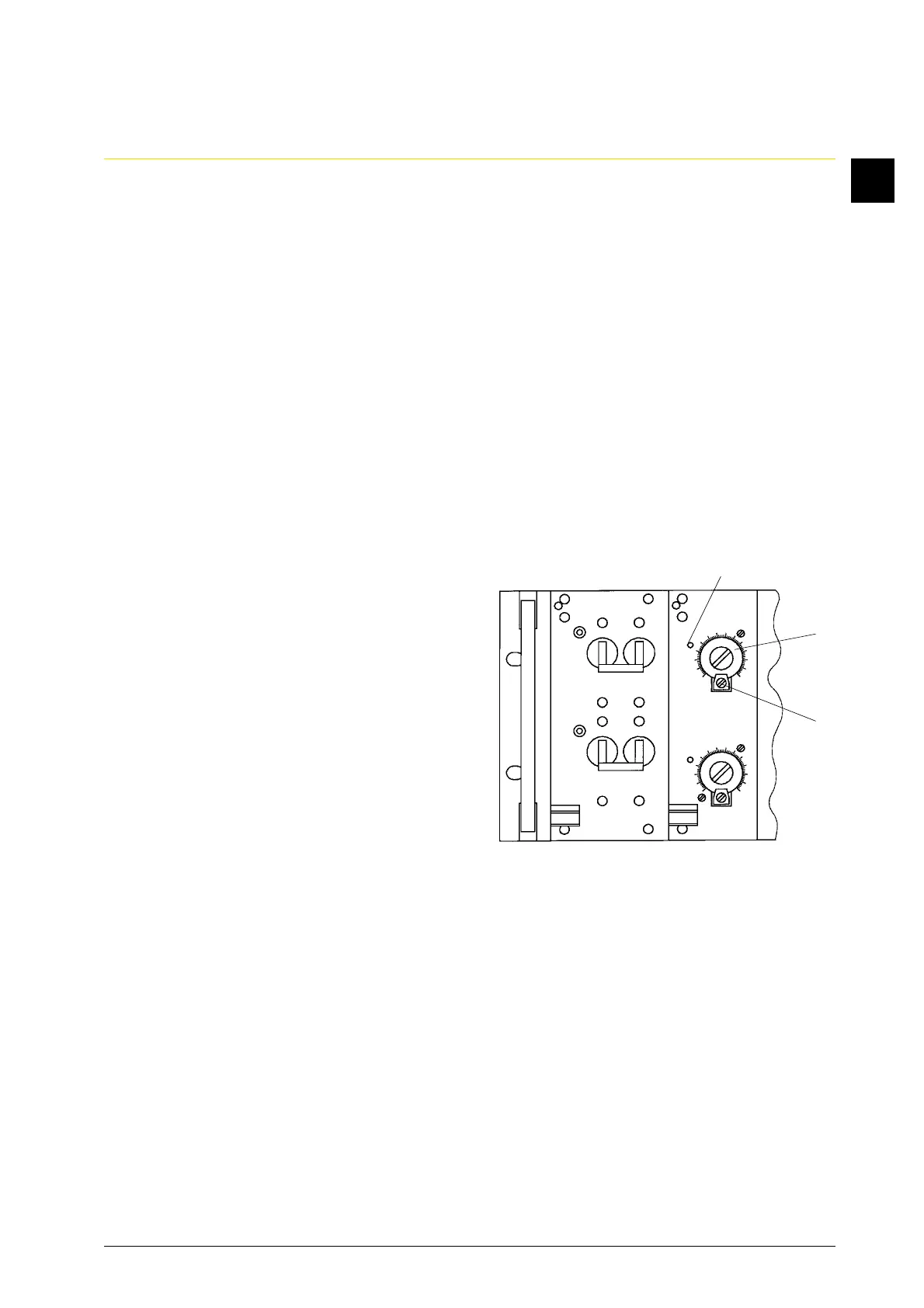

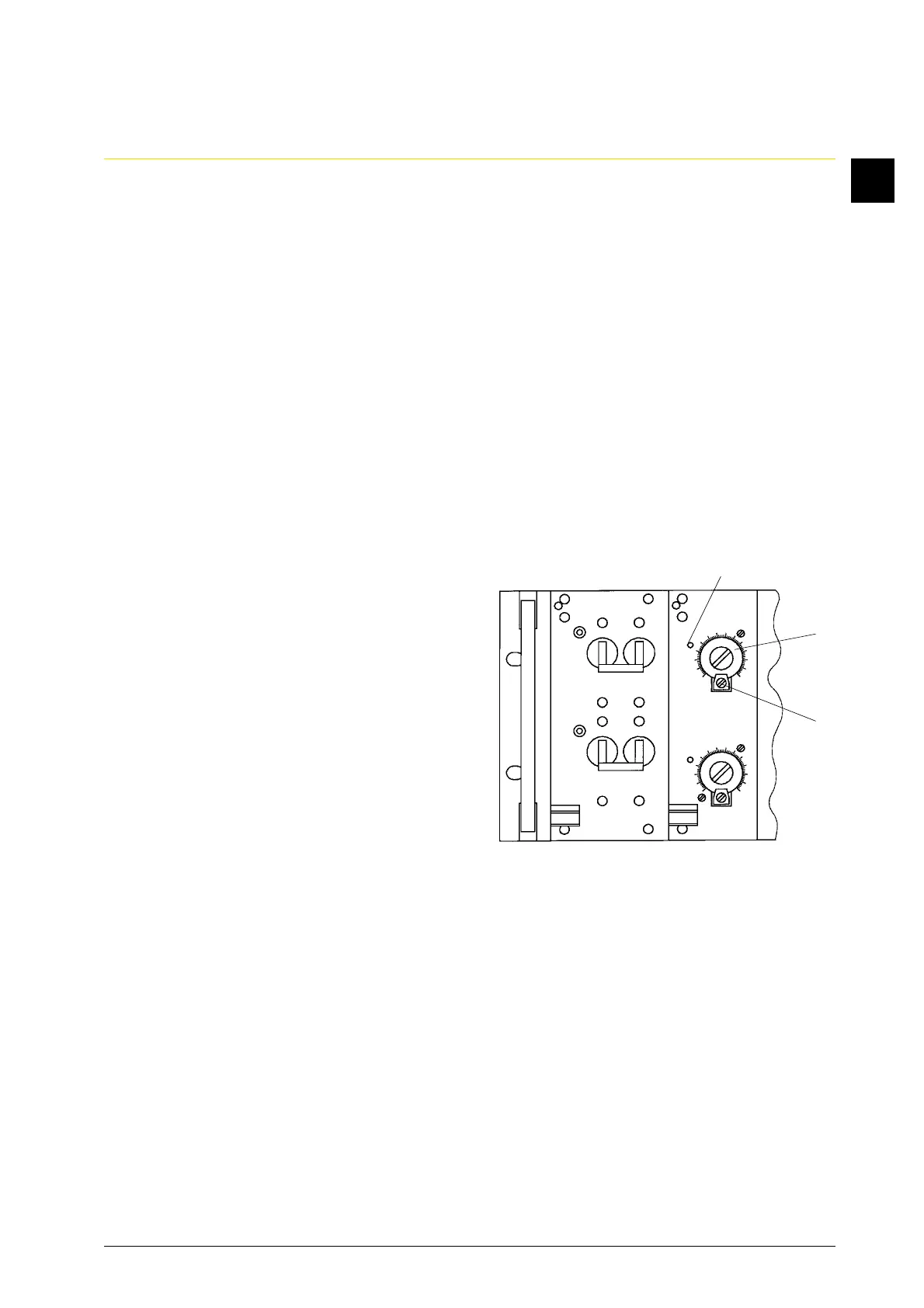

1. Note the rpm switch point setting.

Loosen the pointer locking plate (2) and

set the pointer (1) at the highest engine

speed.

The output relay on the plug-in card

must switch and the luminous diode (3)

on the dial will go out (Fig. 1).

2. Turn the pointer carefully to the left

towards 0 rpm. When reaching the

engine speed, the output relay will

switch and the diode on the dial must

light up (switch hysteresis ± 25 rpm).

3. Set the pointer again at the original rpm

switch point and lock it.

If the rpm switch does not work,

proceed as follows in order to locate

the defect:

4. The automatic cut-out F 1.1 and F 2.1 on the plug-in card A1 in the rpm switch installation

must be switched on.

At constant speed and with the setting as under point 1, continue as follows:

5. Voltage check at the plug-in socket contacts of the plug-in frame.

5.1 Supply (24 V DC at contact z16 and z20, contact z20 positive).

A 1

F 1.1

F 2.1

A 2

3

1

2

Ĺ

Ĺ

Fig. 1

Loading...

Loading...