Cylinder Liner

Maintenance / Disassembly

A5.05. 03.04.01.00

30000

M20

en / 30.05.2000 IB021527 1/1

03

Ĺ

See also: 01.06.01.nn, 02.06.01.nn

Spare parts list: B1.05.03.2.1110

Time requirement: 1 Pers./ 0,50 h

Personnel qualification: skilled engine hand

---------------------------------------------------------------------------------------------------------------------

Operating medium: Heavy fuel and distillate fuel

Maintenance:

Removal of cylinder liners and changing O-rings after 30,000 h

Tools:

Device for mounting and extracting the W1 2.9216-A

cylinder liners

Sequence of operations:

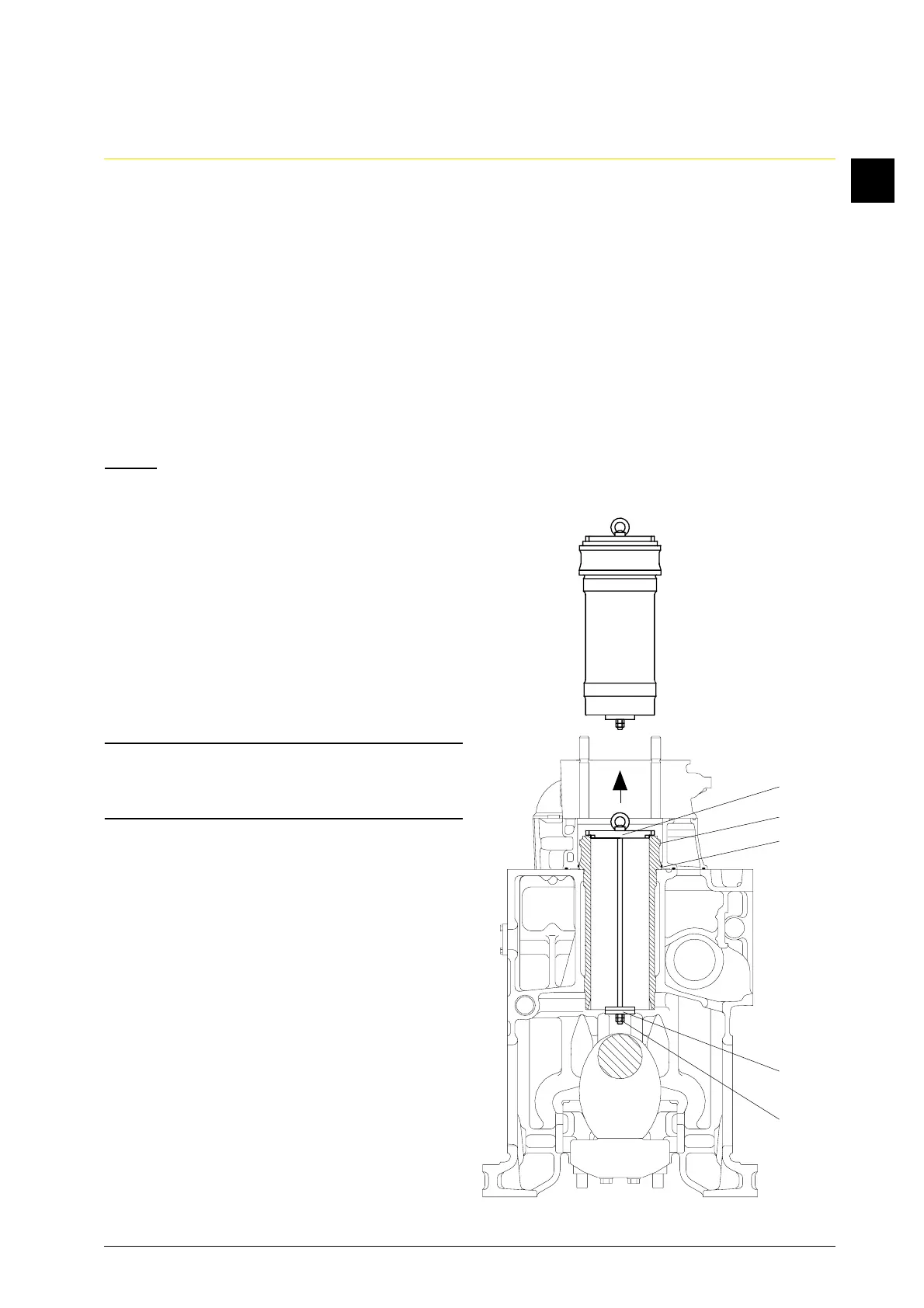

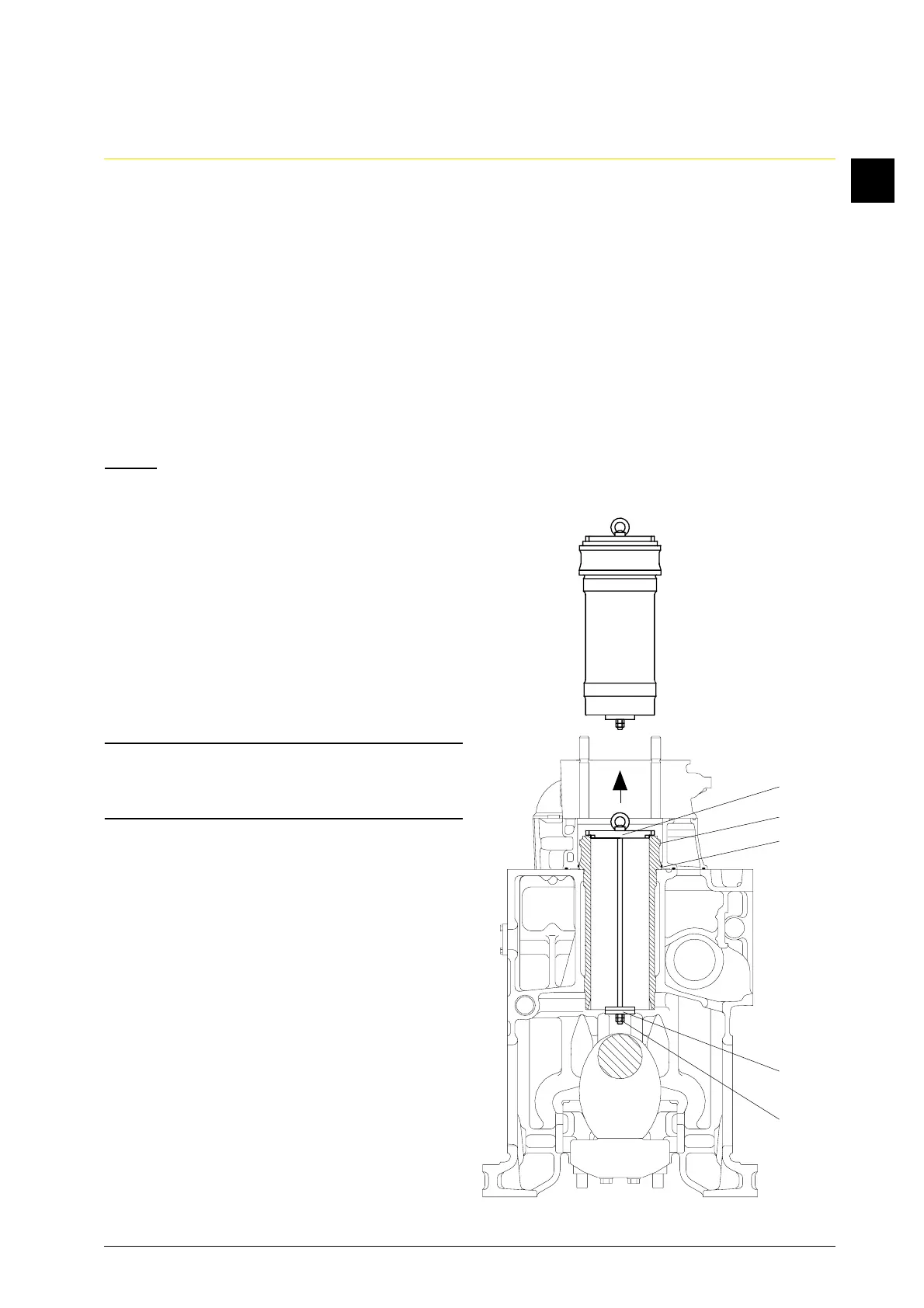

1. Put upper crosshead half (Fig. 1/W1)

with threaded rod and eye bolt on liner

collar.

2. Mount lower crosshead half (1) and

tighten both crosshead halves firmly

with each other with nuts (2).

Attention:

The cylinder liner holding device must

be removed.

3. Attach the extracting device to a crane

and lift the liner along its centre line out

of the cylinder and put it down.

4. Remove O-rings (Fig. 1/3 and 4) at the

cylinder liner collar and in the cooling

water distributor housing. Thoroughly

clean the sealing surfaces and annular

grooves for the

O-rings.

5. Clean the seat of the liner collar and the

fir for the upper and bottom end of the

liner in the cylinder.

6. Clean the cooling water zone at the cy-

linder liner collar.

W1

3

4

1

2

Fig. 1

Loading...

Loading...