Exhaust Valve Cones

Repair / Checking

A5.05. 01.08.01.02

M20

en / 12.10.2000 IB022659 2/5

01

Ĺ

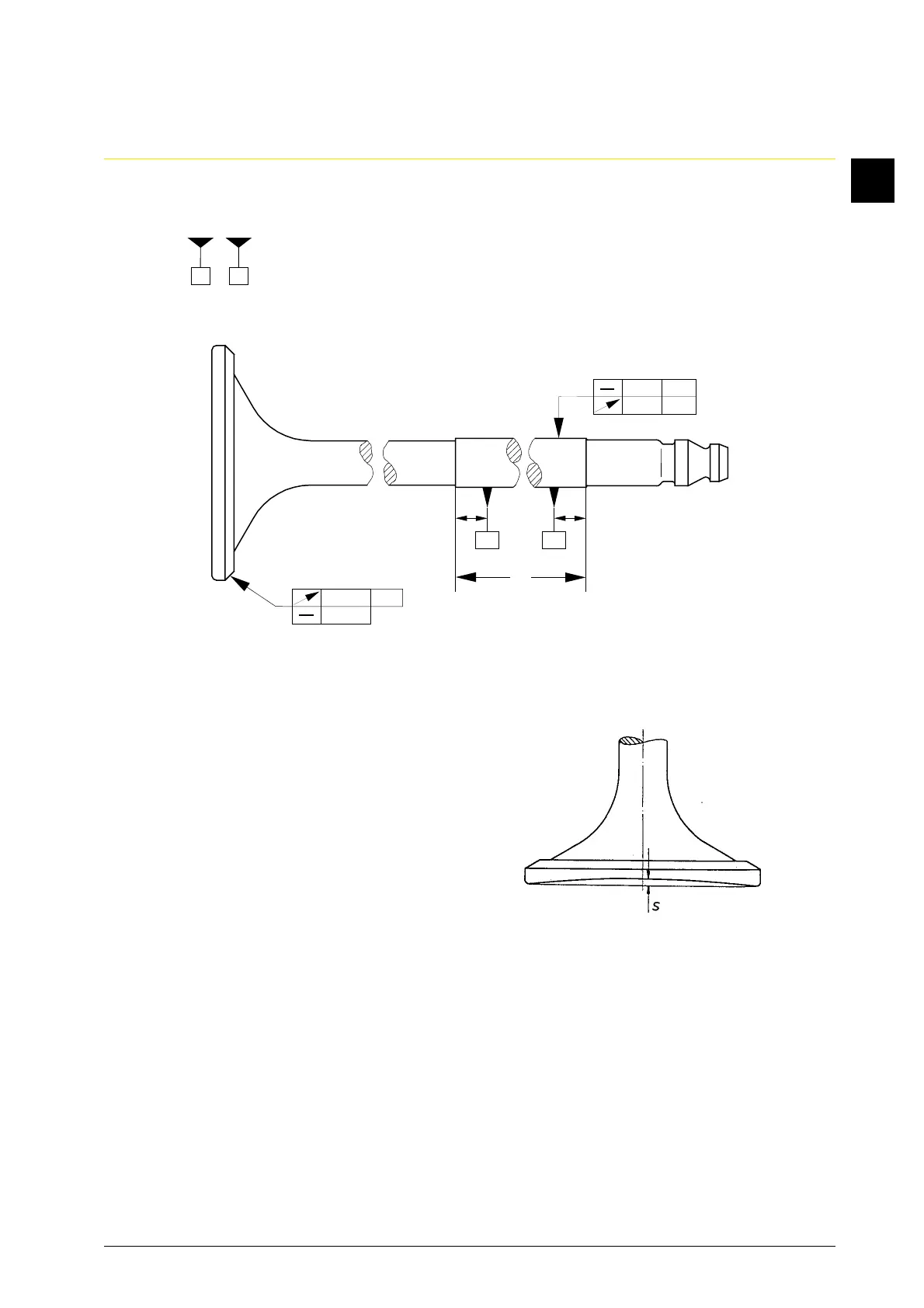

•when the deviation from the straightness is not greater than the following values (Fig. 1).

Measuring range “s” = 200 mm

= support points for test device

•when the radial run-outs of the valve cones do not exceed the following values:

1.2 Valves cannot be reused when

•the valve cone face is damaged

(cracks,blowholes)

•the wear caused by corrosive material

is

> 2 %

of the valve head diameter

(comparison with new valve)

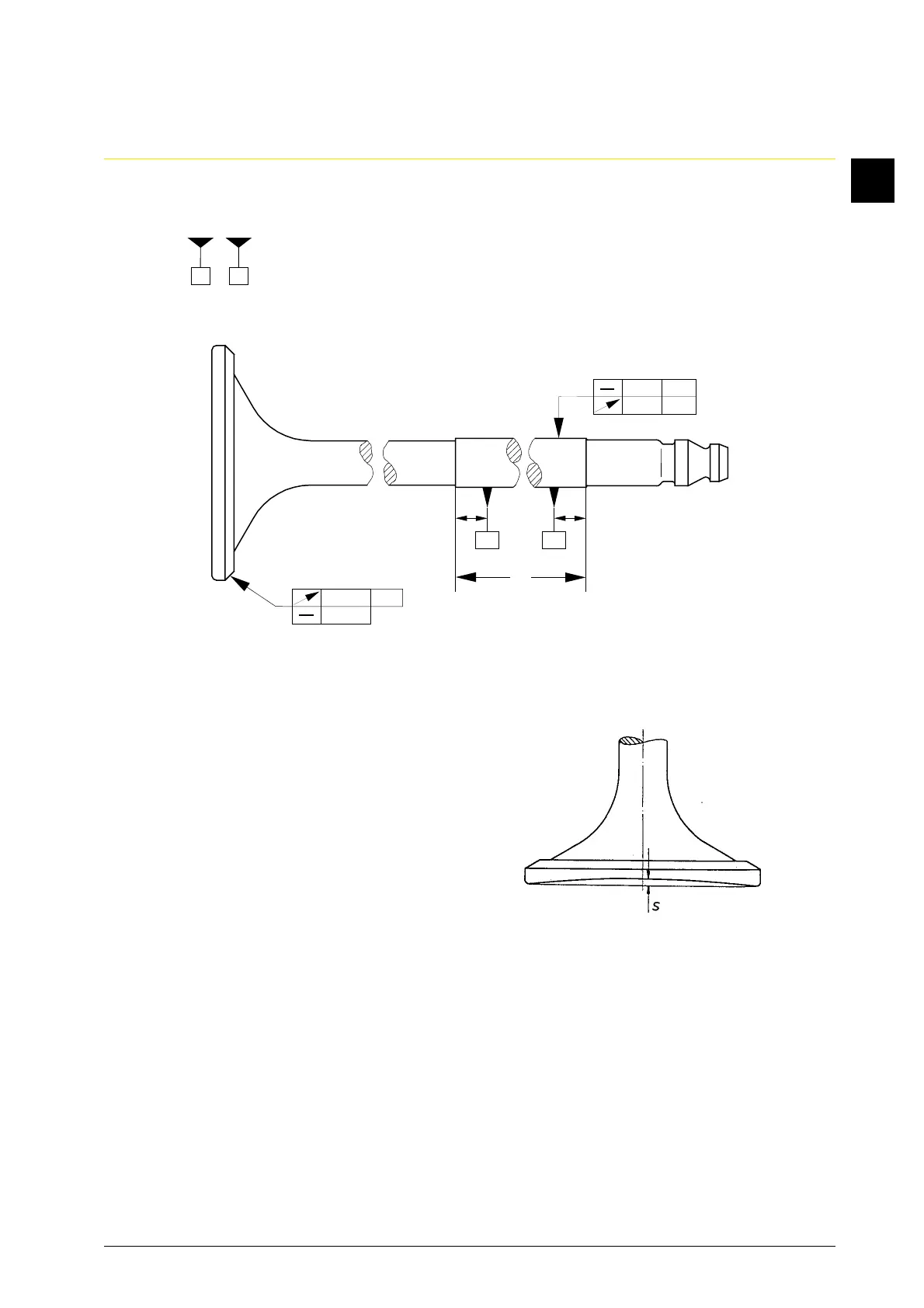

•concave burns “s” caused by high-

temperature corrosion at the lower

side of the valve head

> 1.5 mm (Fig. 2)

•the lower part of the valve head

indicates severe pitting (formation of

so-called “paving stones”)

•corrosion pits and mechanical

damage in the area of the valve stem,

stem transition and valve head

•refinishing limit dimension is

exceeded.

A B

0,02

0,04 AB

A B

s

0,02

0,006

AB

20 20

Fig. 1

Fig. 2

Loading...

Loading...