Inlet Valve Cones

Repair / Checking

A5.05. 01.08.01.04

M20

en / 30.07.2001 IB023324 3/5

01

Ĺ

2. Cleaning

Clean the valve cone, e.g. blasting with

glass beads. Cleaning with sharp-edged

tools as well as pickling with inorganic

acids (hydrochloric acid, sulphuric acid,

hydrofluoric acid etc.) is not allowed.

3. Repair (refinishing of the valve cone

face)

Note:

Refinishing should always be carried

out professionally on precision spindle

grinding machines. If no such machine

is available, the valves should be given

to a MaK workshop for regrinding.

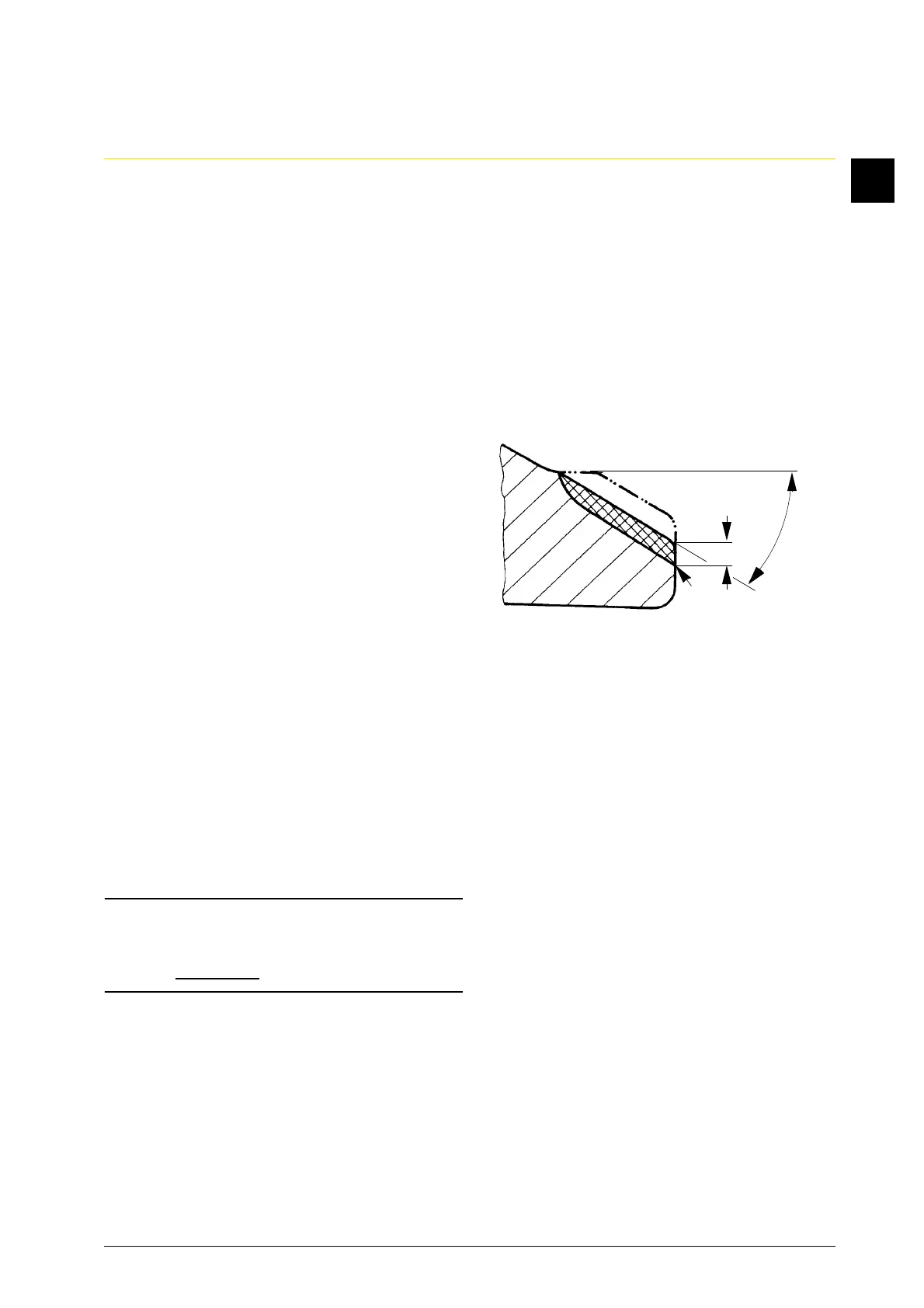

3.1 Regrind valve cone faces in accordance

with prescribed angle (Fig. 3). Do not

refinish existing concave fillet.

3.2 The appropriate information of the

grinding machine manufacturers is to

be observed during grinding.

3.3 Determine the dimension between

visible edge of the base metal plating

“X” and the outer edge of the seat after

completing the grinding process.

Replace the valve cone if the actual

dimension falls below the minimum

dimension.

3.4 Outer edge rounded with stone.

Attention:

When the valve cone is refinished, the

valve seat ring must also be refinished

(01.08.02.nn).

Fig. 3

2

0

°

-

8

’

X

min. 1 mm

Loading...

Loading...