Valve Seat Ring

Repair / Checking

A5.05. 01.08.02.01

M20

en / 15.03.2001 IB023062 4/5

01

Ĺ

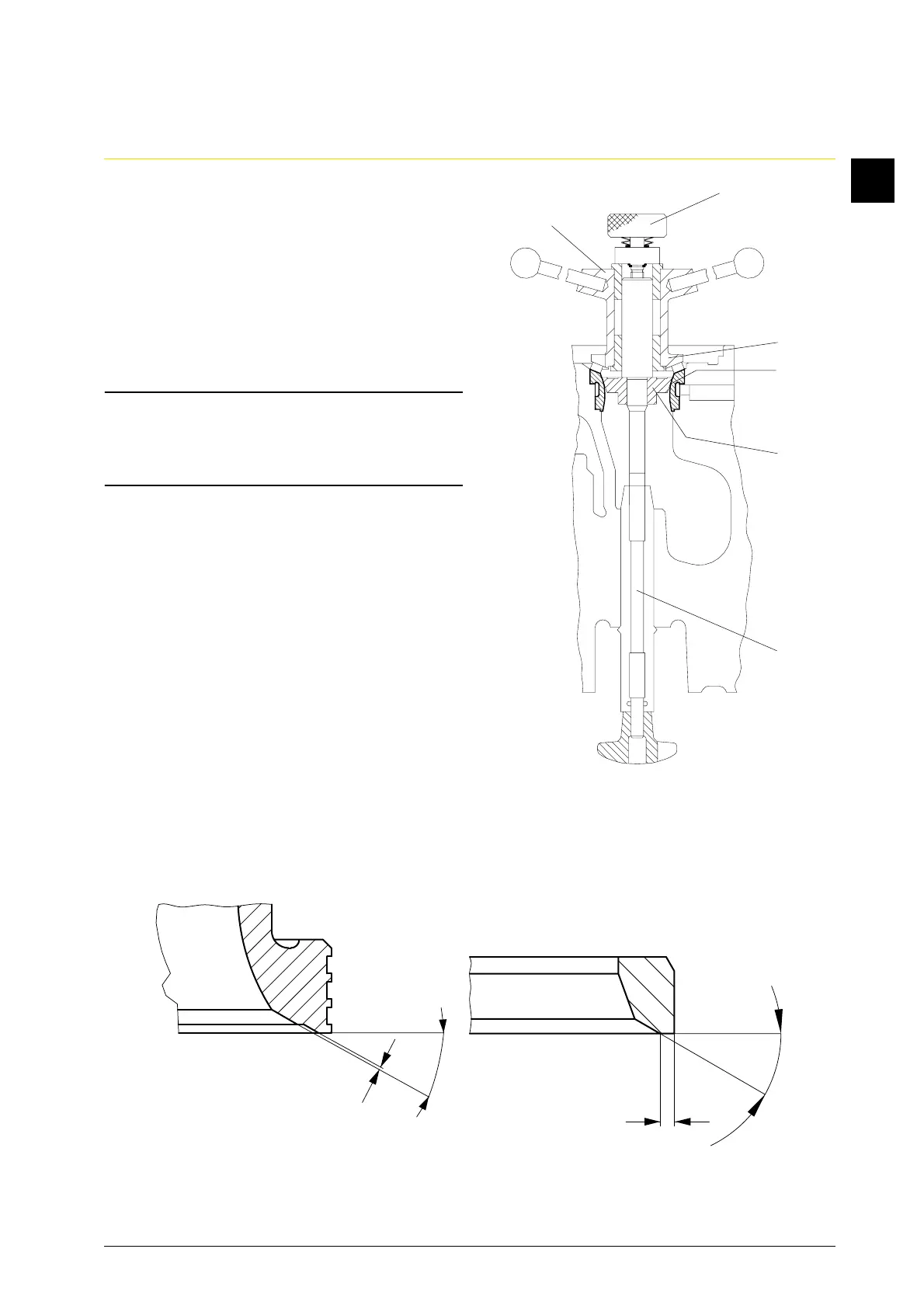

3.1.3 Place cutter head (Fig. 6/2) on greased

mandrel, screw in knurled thumb screw

(1), until resistance becomes

noticeable.

3.1.4 Rotate valve seat (clockwise) uniformly

and slowly and remill the seat in one

operation pass. The cutting of the

cutters must be noticeable. Set the

contact pressure by touch.

Attention:

The machine will rattle when the

contact pressure is too low and/or the

cutting speed is too high.

3.1.5 Prior to finishing the cutting process,

slowly unscrew the knurled thumb

screw (1) and simultaneously rotate the

cutter head.

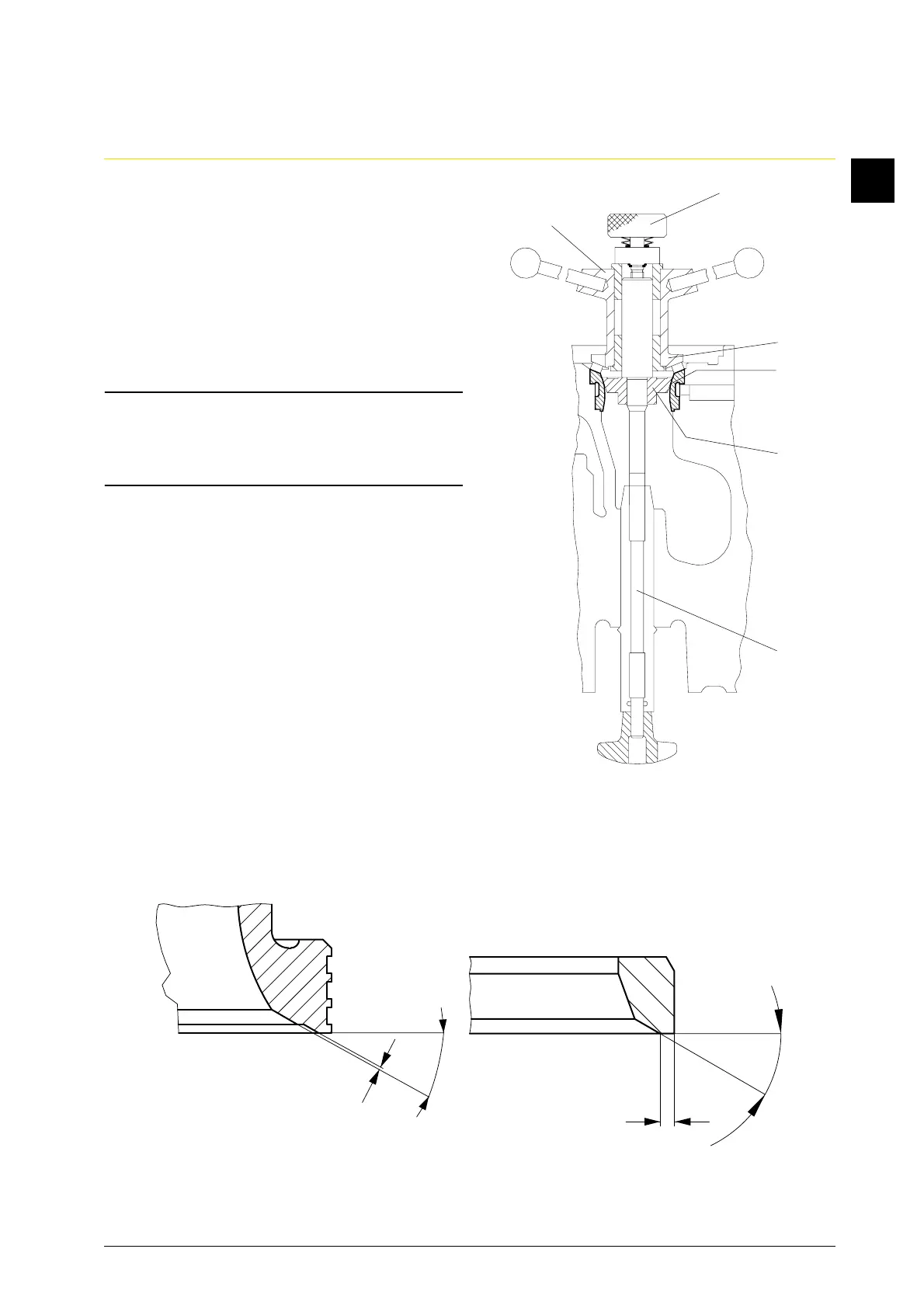

3.1.6 Max. permissible dimension for rewor-

king:

Exhaust valve (Fig. 7):

The shoulder "y" must still remain di-

stinct.

Inlet valve (Fig. 7a):

The dimension for "z" must not drop

below the minimum dimension of 1

mm due to the reworking.

1

2

3

4

5

W2

Fig. 6

z

y

20

° 5' +

5

'

3

0° 5' +

5

'

Fig. 7

Fig. 7a

Loading...

Loading...