Cylinder Head

Repair / Reassembly

A5.05. 01.11.01.00

M20

en / 16.09.1997 IB001353 3/5

01

Ĺ

Note:

Insert all O-rings with vaseline or green grease soap untwisted into grooves.

4. Carefully place cylinder head with cylinder head lifting device (W9) and lifting gear onto

cooling water distributor housing. Avoid jamming of cooling water transition on pushrod

passage.Insert pushrods into cylinder head. Observe fixing pin in the cooling water

distributor ring.

5. Insert new seal (Fig. 1/7) for exhaust flange and align cylinder head. Lubricate screws for

exhaust pipe with “Dag S-5080” high-temperature thread paste and screw in loosely with

resilient sleeves.

6. Tighten the four cylinder head screws

together with the hydr. tightening

device.

Attention:

Max. lift of 5 mm must not be

exceeded.

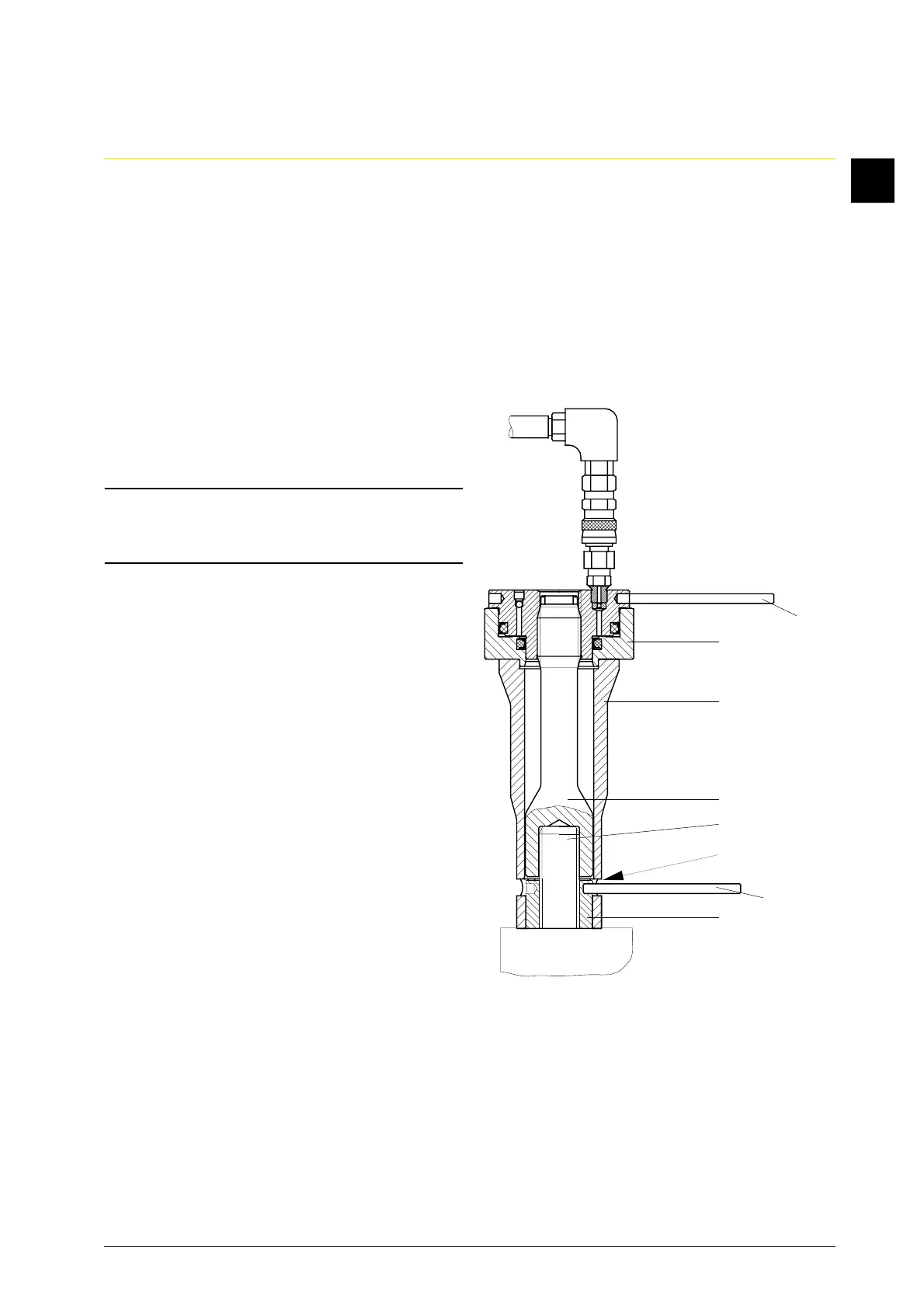

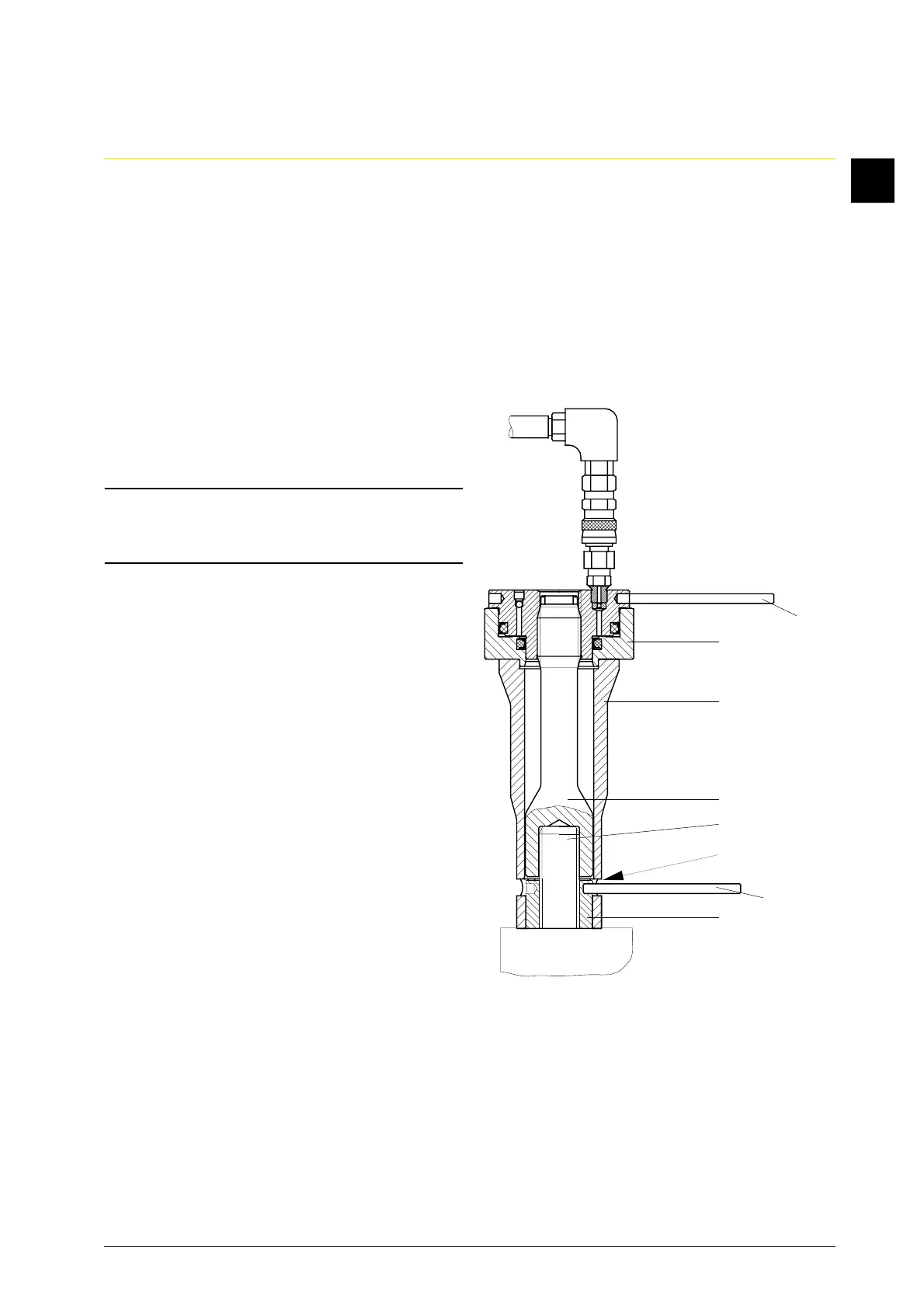

6.1 Tighten round nuts (Fig. 2/12) with pin

(W8) hand-tight.

6.2 Screw spacer (W7) onto cylinder head

screw (11).

6.3 Place bearing ring (W6) over round nut

(12), thereby, make sure the slots (13)

are easily accessible.

W8

W4

W6

W7

11

13

W8

12

Fig. 2

Loading...

Loading...