Main Bearings

Inspection / Disassembly

A5.05. 02.05.01.00

15000, 30000

M20

en / 30.05.2000 IB021376 3/5

02

Ĺ

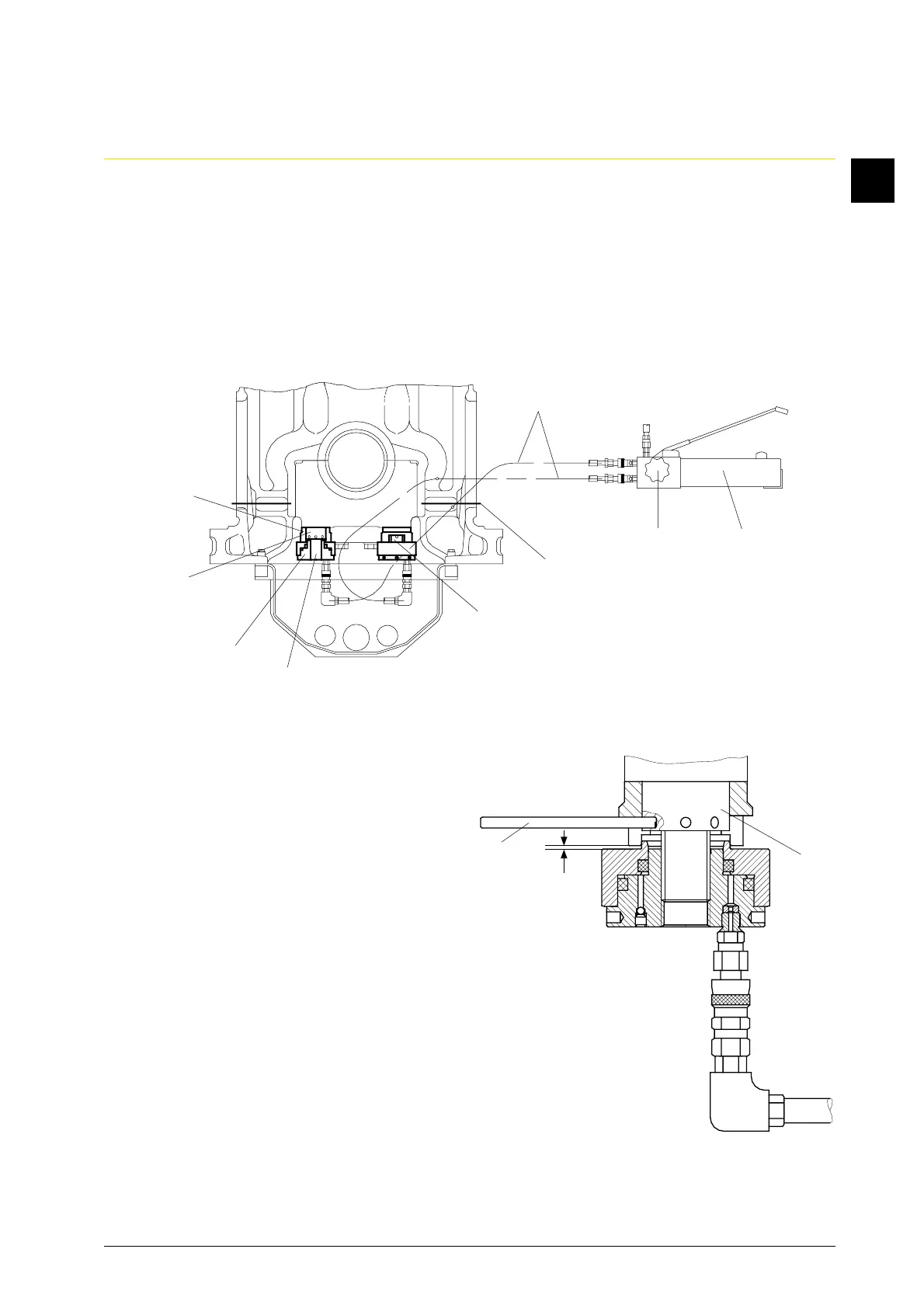

1.3 Loosen bearing bolts with hydraulic tightening equipment.

1.3.1 Remove hexagon screws (Fig. 2/11) of the main bearing which is to be removed.

1.3.2 Place bearing ring (W1) over the round nut (12) and turn hydraulic tensioning element

(W2) on bearing bolt (13) and screw against bearing ring. Make sure that the slots (14) are

easily accessible.

1.3.3 Link hydraulic tensioning element (W2) with high-pressure pump (W3) via high-pressure

hose (W4) and press onto block length (Valve [Z] open at the high-pressure pump).

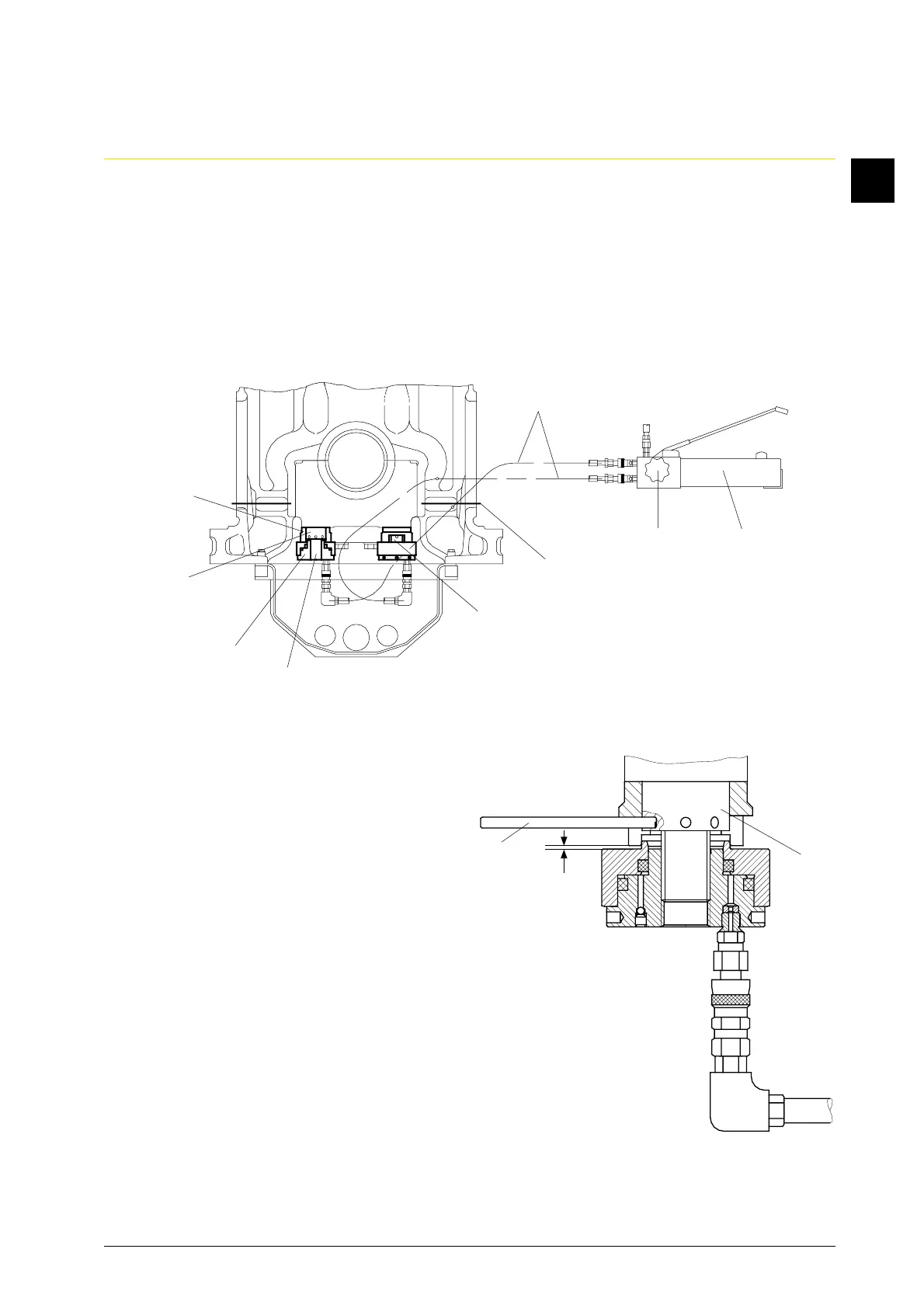

1.3.4 Set a gap “s” of 2.5 mm (Fig. 3)

between bearing ring and tensioning

element.

1.3.5 Stretch both bearing bolts in one work

sequence with

p = 750 bar

and loosen round nuts (12) with pin

(W5).

Note:

Prestress bearing bolts by approx.

50 bar more if required. If the pressure

is increased further the round nut might

stick due to stretching of the bolt

thread.

W4

ZW3

11

14

W1

12

W2

13

Fig. 2

s

W5

12

Fig. 3

Loading...

Loading...