Main Bearings

Inspection / Disassembly

A5.05. 02.05.01.00

15000, 30000

M20

en / 30.05.2000 IB021376 5/5

02

Ĺ

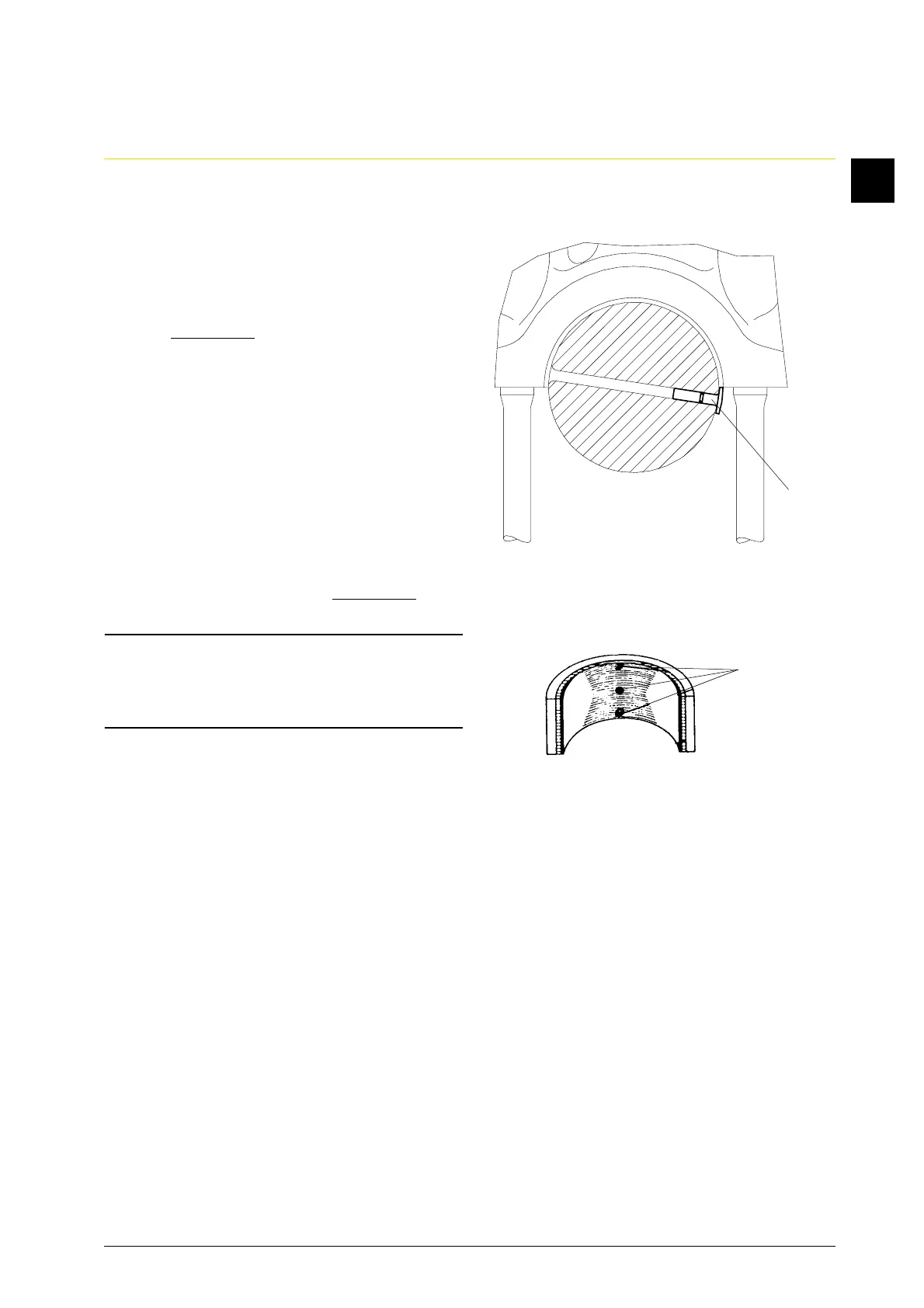

1.8 Insert dog (Fig. 6/W7) into oil bore of

the crankshaft and twist out top bearing

shell to the exhaust side.

1.9 Check AL-groove bearings in

accordance with rating criteria

02.03.09.nn.

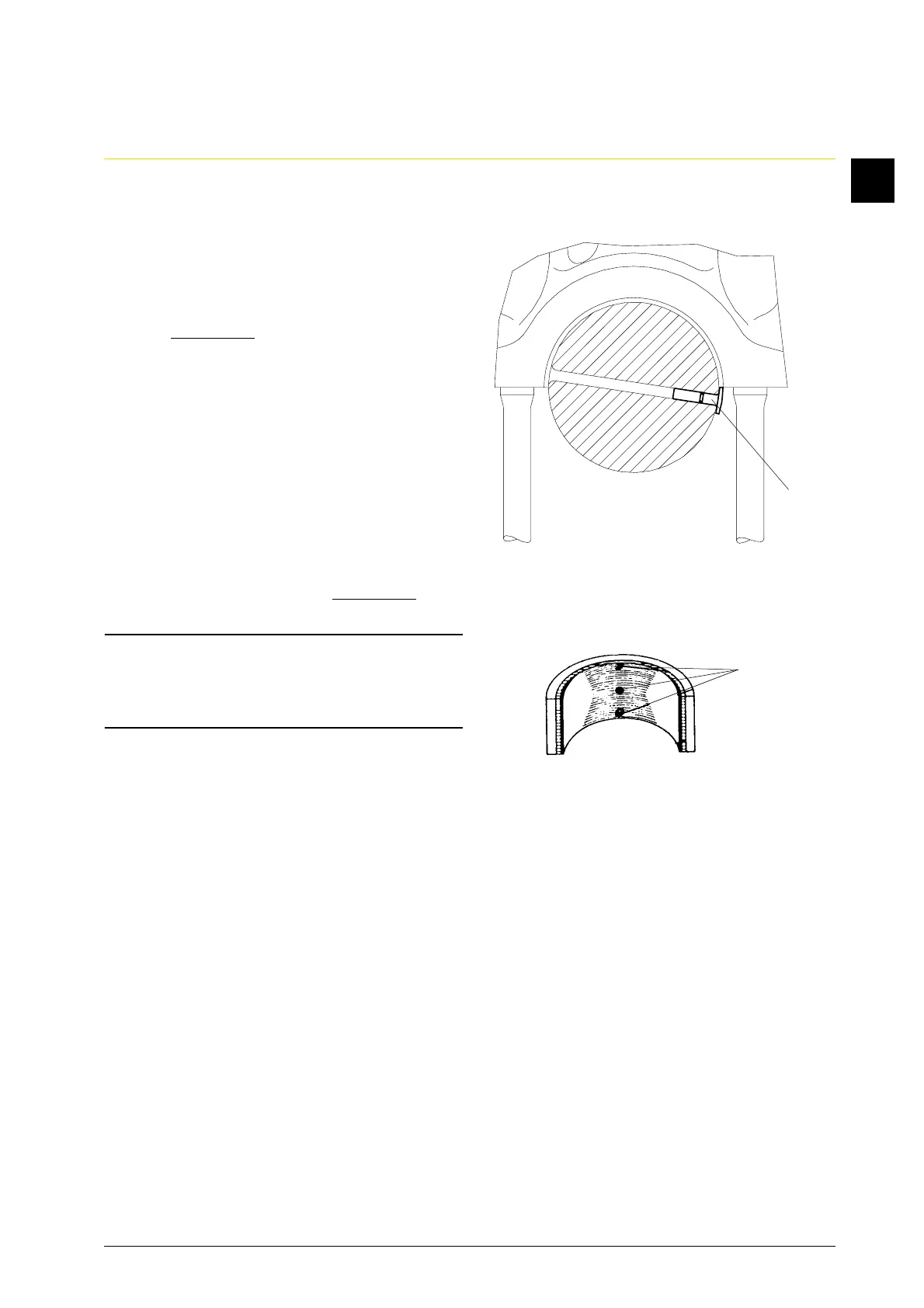

1.10 In the case of 2-material bearings, check

wearing of the wall-thickness in the

main load region at check points

(Fig. 7/X) with micrometer caliper.

Wear = new dimension -

actual dimension

New dimension: 4.927

-0.015

mm

In the case of a wear of > 0.05 mm the

bearing shells are to be changed.

Further rating criteria, 02.03.07.nn.

Attention:

If a bearing shell has to be changed

during inspection, the adjacent

bearings are also to be checked.

Fig. 6

W7

Fig. 7

X

Loading...

Loading...