Main Bearings

Inspection / Disassembly

A5.05. 02.05.01.01

15000, 30000

M20

en / 30.05.2000 IB021418 2/5

02

Ĺ

Note:

The bearing caps and bearing shells are marked continuously on the camshaft side starting

from the clutch side according to which cylinder they belong and must not be exchanged.

New parts are to be marked correspondingly.

Even within the prescribed interval, the main bearings are to be removed, checked and

measured if:

Substructure deformations and/or crank web deflection changes after crashes appear and/

or if the connecting rod bearings are found in a poor condition.

Sequence of operations:

1. Remove main bearing.

1.1 Open driving room covers on camshaft and exhaust side and turn crankshaft into favorable

position for removing.

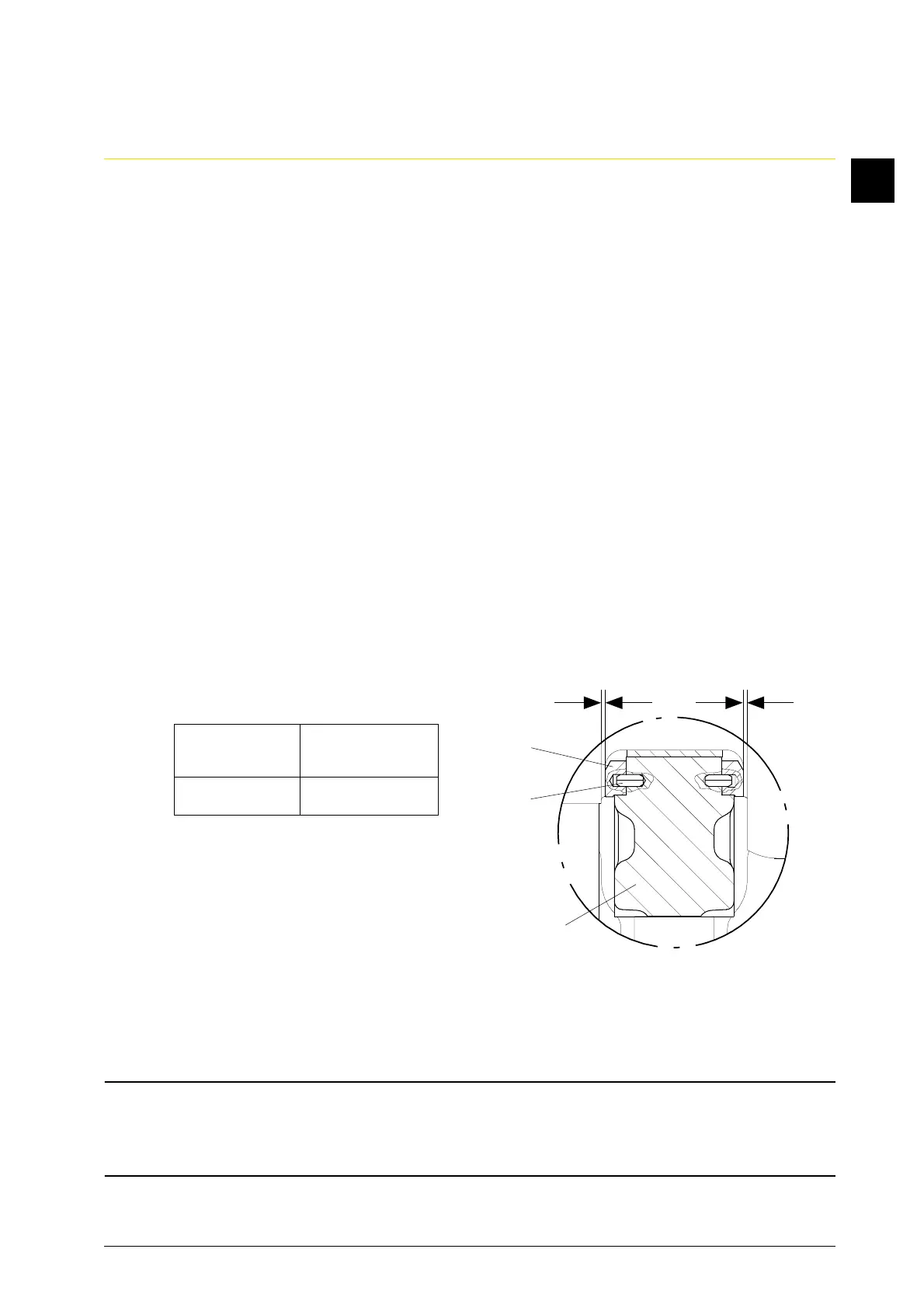

1.2 Measure axial play “s” by the locating bearing (Fig. 1).

1.2.1 Place gage with magnetic holder on flywheel set and align at the cylinder block and

crankcase.

1.2.2 Offset crankshaft axially, until bearing is on one side. Set gage to “zero”. Shift crankshaft in

the opposite direction and read off axial clearance “s” at gage.

1.2.3 Axial play “s”:

s = s

1

+ s

2

New clearance Limit clearance

mm mm

0.23 - 0.4 0.6

If the limiting clearance is exceeded,

renew the stop disk segments and

bearing shells in pairs.

Note:

Lower stop disk halves (Fig. 1/1) are

pinned with clamping pins (2) at the

bearing cap (3).

Attention:

It is imperative to mark the stop disks before a possible disassembly for checking

purposes, so that they cannot be interchanged.

Afterwards re-assemble them immediately!

s

1

s

2

Fig. 1

3

2

1

Loading...

Loading...