Main Bearings

Inspection / Disassembly

A5.05. 02.05.01.01

15000, 30000

M20

en / 30.05.2000 IB021418 4/5

02

Ĺ

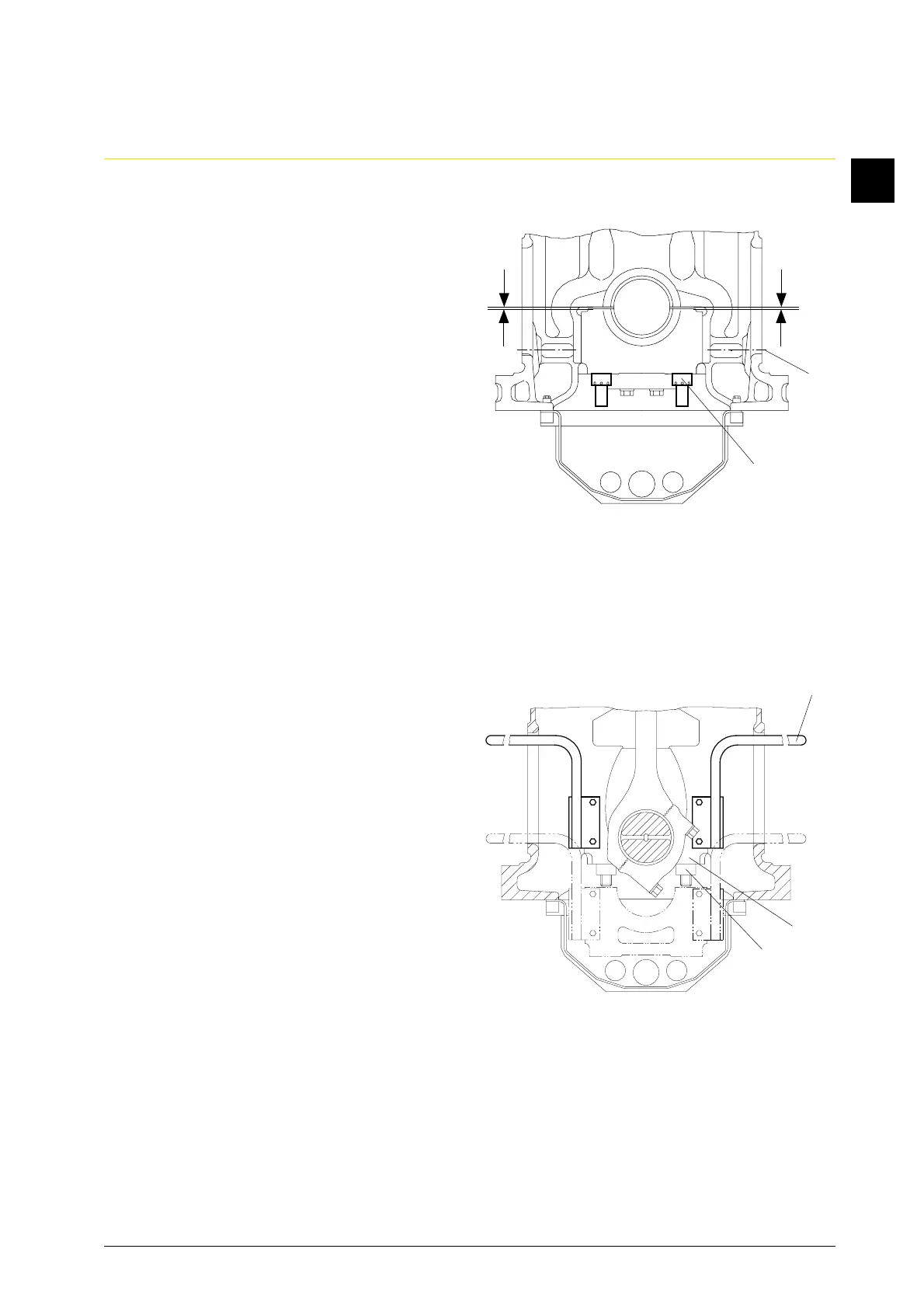

1.4 Measure clearance.

1.4.1 Remove hexagon screws (Fig. 4/11) of

the respective main bearing on exhaust

and camshaft side.

1.4.2 Hydraulically loosen both round nuts

(12) in accordance with sequence of

operations 1.3.

1.4.3 Relieve hydr. removal equipment and

remove.

1.4.4 Tighten round nuts in turn by hand and

uniformly, until the parting faces of the

bearing shells just come into contact

with each other.

1.4.5 Measure clearance “K” between

cylinder block and crankcase and

bearing cap on exhaust and camshaft

side with feeler gage and add the two

measured values.

K = K

A

+ K

S

Clearance “K” Operating limit value

mm mm

0.50 - 0.80 0.4

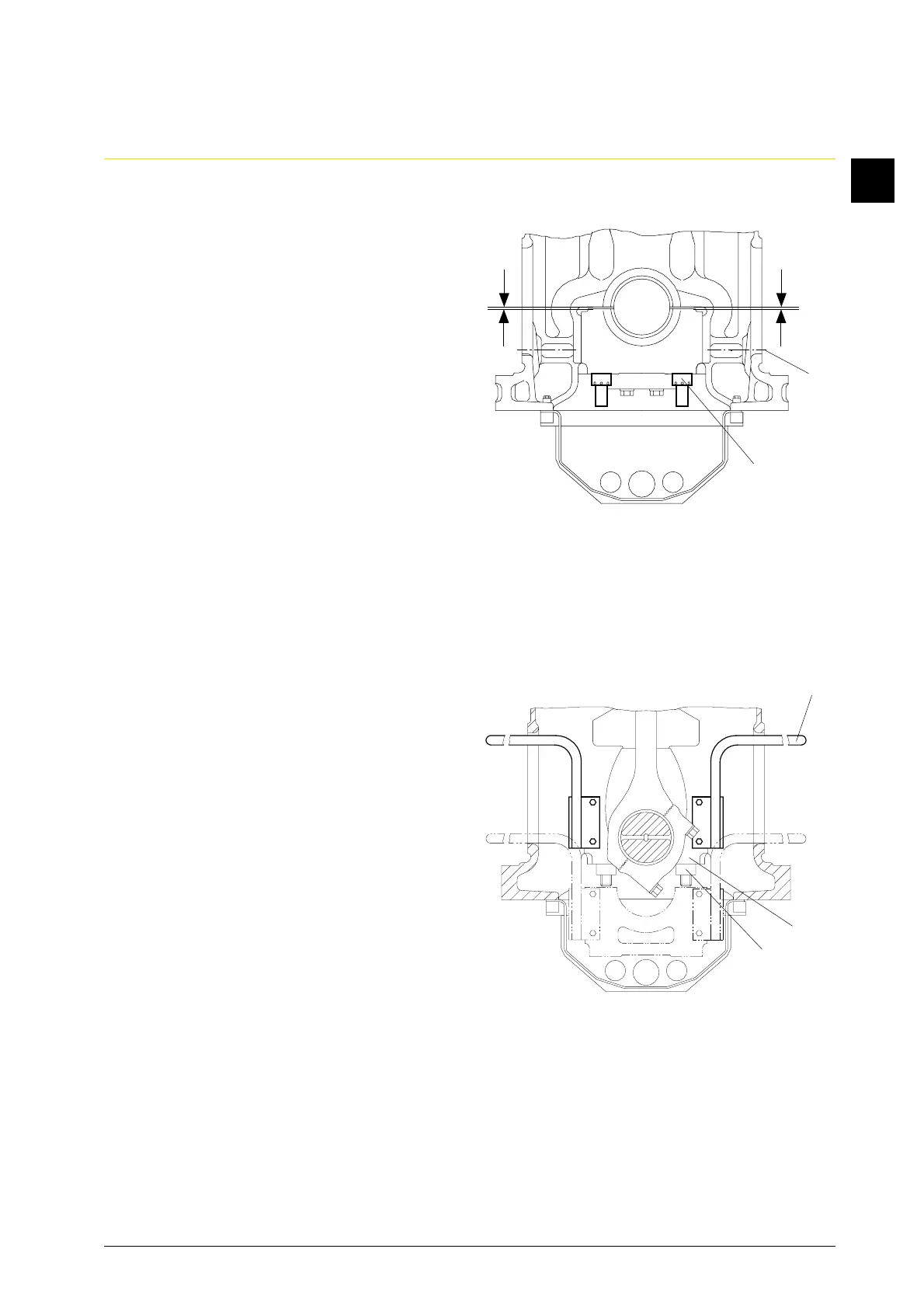

1.5 Screw lowering device (Fig. 5/W6) onto

bearing cap (21) on exhaust and

camshaft side.

1.6 Twist down round nuts (12) uniformly

from bearing bolts and lower bearing

cap carefully. Bearing cap is suspended

on lowering device in the cylinder

block and crankcase.

1.7 Remove lower bearing shell from

bearing cap.

Fig. 4

12

K

A

11

K

S

W6

21

12

Fig. 5

Loading...

Loading...