Piston Rings and Grooves

Inspection / Checking

A5.05. 02.07.01.01

7500, 30000

M20

en / 16.07.2001 IB021477 2/3

02

Ĺ

1.4 Remove the piston rings only with the

correct tool (Fig. 1/W1). Maintain

previous position of the rings referring

to the mounting position of the piston

given in the measuring sheet.

1.5 Clean piston rings.

1.6 Check the the chrome layer for wear,

especially at the cut and at the opposite

side. Renew all rings of this piston even

if only parts of the chrome layer is no

longer visible.

If the chrome layer of one piston ring

has been worn, check the rings of all

pistons.

1.7 Clean the piston, ring grooves and oil return holes for the scraper scraper ring.

1.8 Smooth slight friction and seizing marks with an oily fine emery cloth or fine carborundum

stone. Renew the piston in case of heavy damage or deep scores.

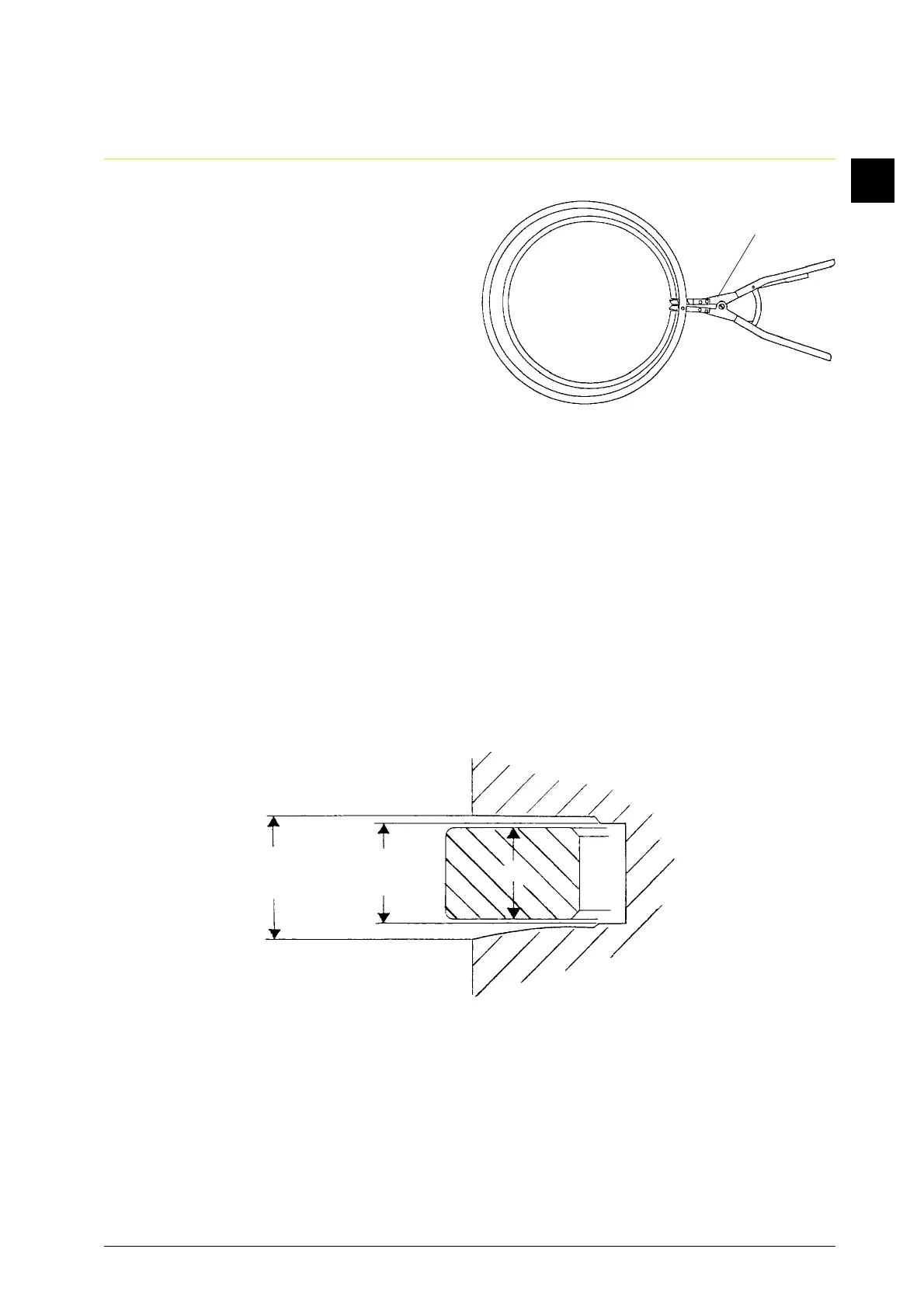

1.9 Measure the groove width h

N

(Fig. 2) in the front area of the groove in longitudinal and

transverse directions of the engine. When exceeding the limits, have the ring grooves

reconditioned by MaK.

1.10 Measure the ring thickness h

R

(Fig. 2) at 4 different points.

h

N1

= new

h

N2

= worn

W1

Fi

. 1

h

N

h

R

h

N

Fig. 2

1

2

Loading...

Loading...