Piston Rings and Grooves

Inspection / Checking

A5.05. 02.07.01.02

7500, 30000

M20

en / 16.07.2001 IB022434 3/3

02

Ĺ

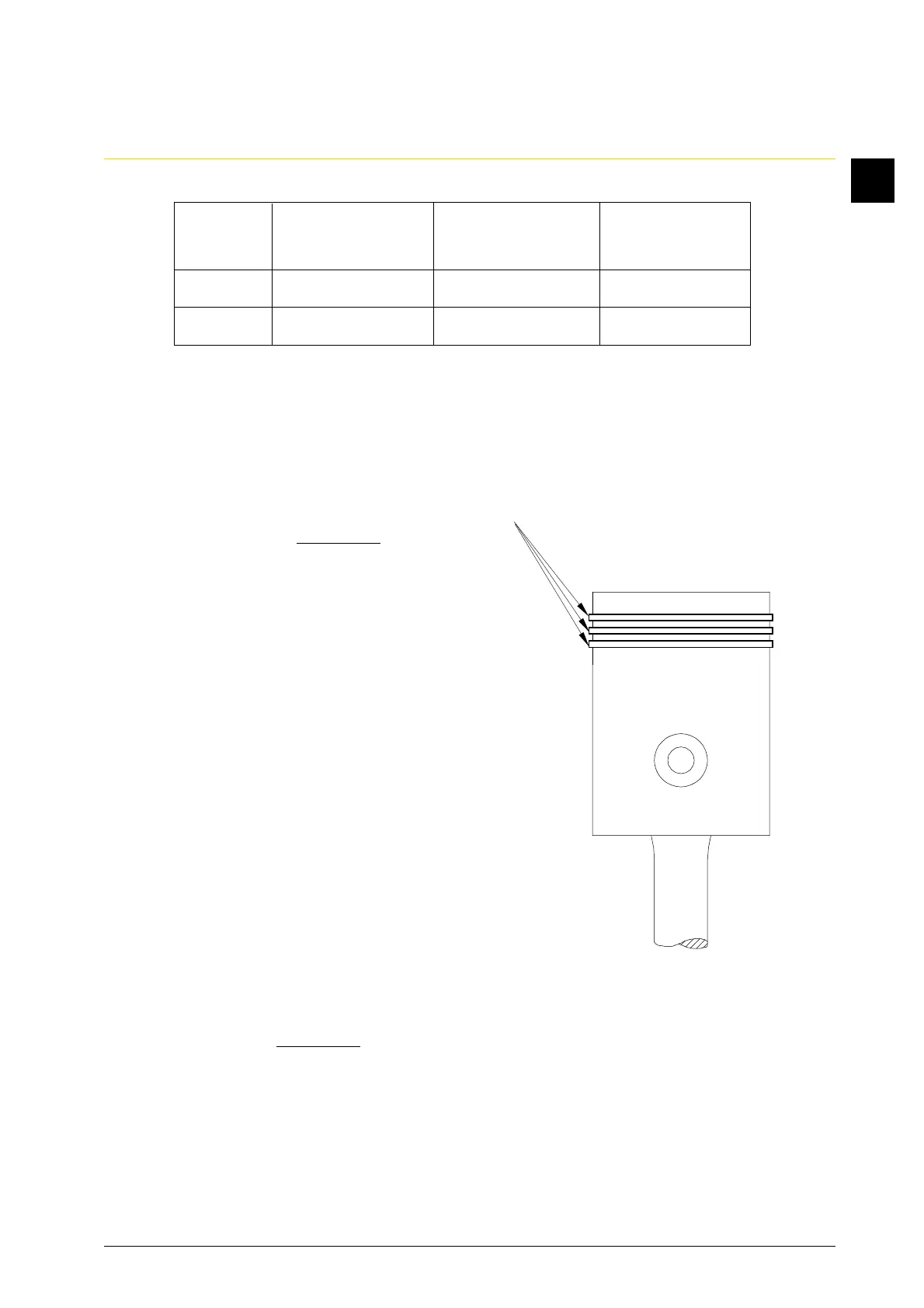

1.11 Determine the clearance by calculation and check it against the table.

Ring thicknes h

R

Groove width h

N

Limit of h

N

- h

R

Groove Nominal Wear limit mm

mm mm

1 – 2 4.95 5.6 0.65

36 6.5 0.5

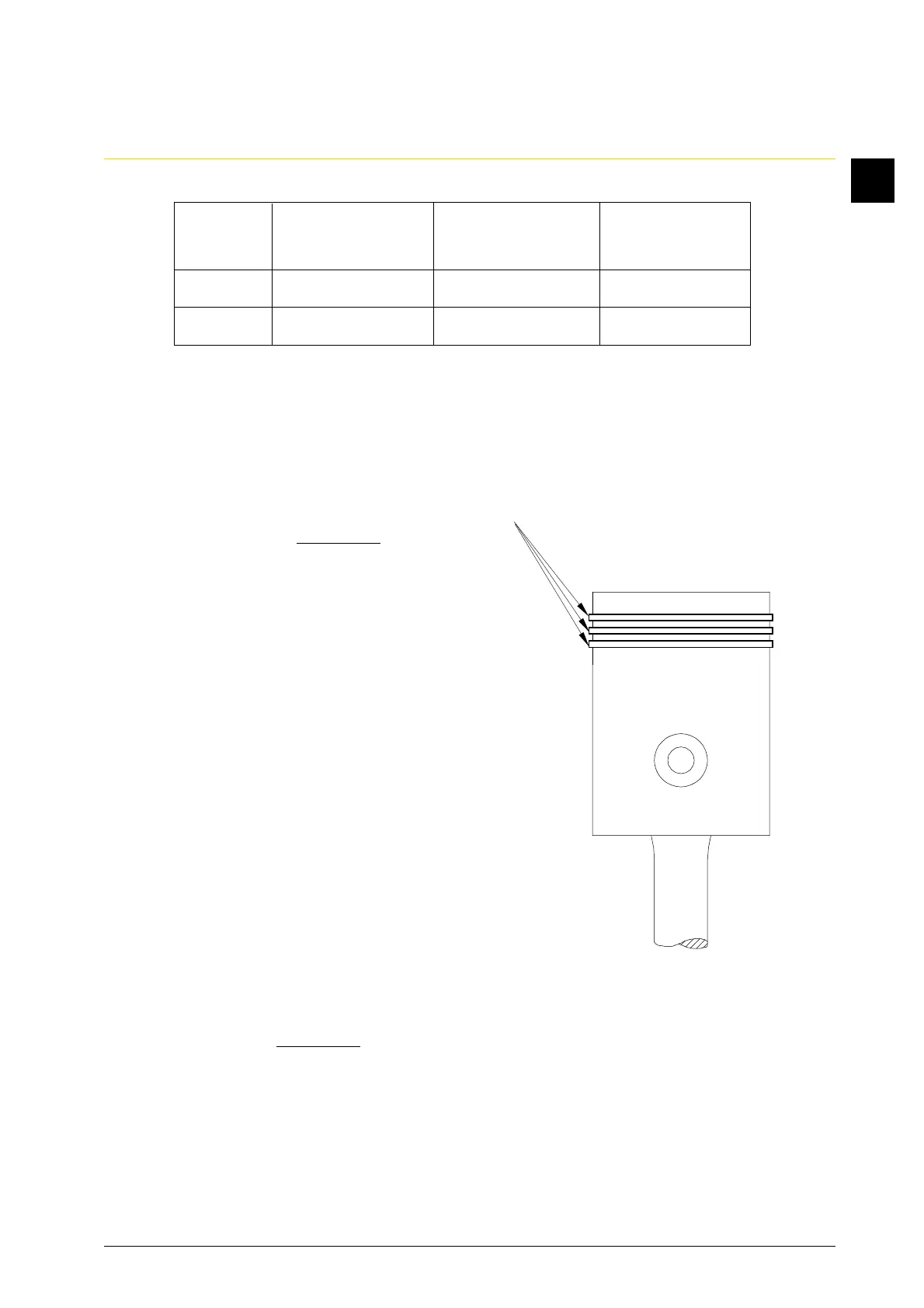

1.12 Fit piston rings with the marking facing

upwards (Fig. 3/X) and with the ring

stops into the ring grooves

alternatingly opposite in engine

longitudinal direction.

2. Maintenance (30,000 h)

2.1 Draw all pistons (02.06.01.nn).

2.2 Check the state of lubrication and

appearance of the running surface of

the piston and clean it.

2.3 Remove the piston rings with piston

ring expander (Fig. 1/W1). Maintain

previous position of the rings referring

to the mounting position of the piston

given in the measuring sheet.

2.4 Clean all ring grooves.

2.5 Measure the groove width h

N

in

accordance with sequence of

operations 1.9.

2.6 Renew all compression and scraper

rings.

2.6.1 Fit piston rings with the marking facing

upwards (Fig. 3/X) and with the ring

stops into the ring grooves

alternatingly opposite in engine

longitudinal direction.

2.7 Fit all pistons (02.06.02.nn).

Fig. 3

X

Loading...

Loading...