Piston

Maintenance / Reassembly

A5.05. 02.10.01.01

M20

en / 17.06.1998 IB004785 2/3

02

Ĺ

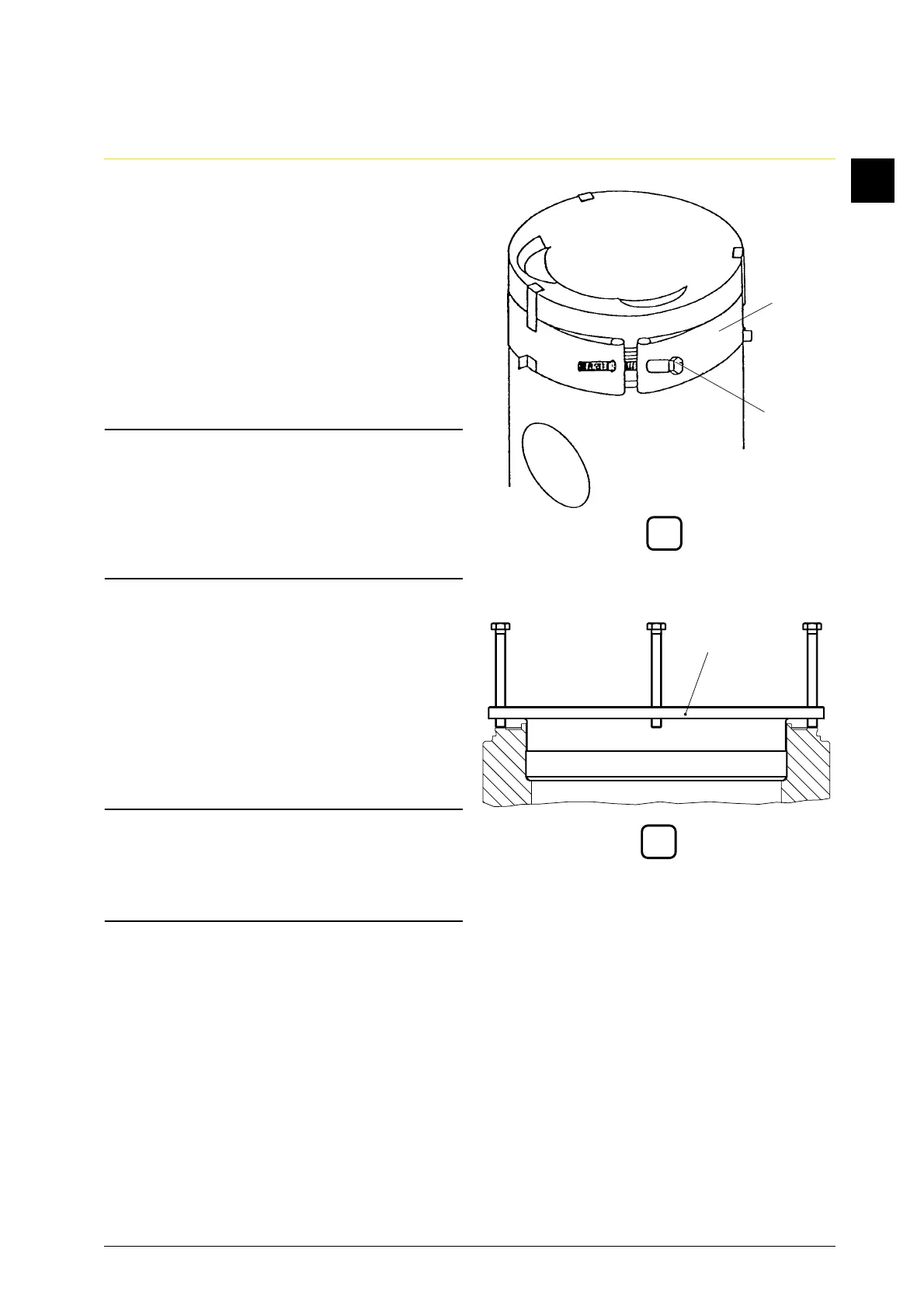

3. Slacken the tightening screw (fig. 1/10)

until the piston insertion device (W4)

has been relieved and can be guided

freely over the piston rings.

4. Apply Molykote paste "G-Rapid Plus" to

the thread and contact surface of the

tightening screw (10).

5. Place the piston insertion device (W4)

over the piston ring zone and tighten

the tightening screw (10).

Attention:

Make sure the piston rings do not sit

on the outer edge of the ring groove

when tightening the tightening screw.

Eliminate any faulty gripping by

tapping the piston insertion device

slightly.

6. Check the floating position of the rings

by turning the piston insertion device

(W4).

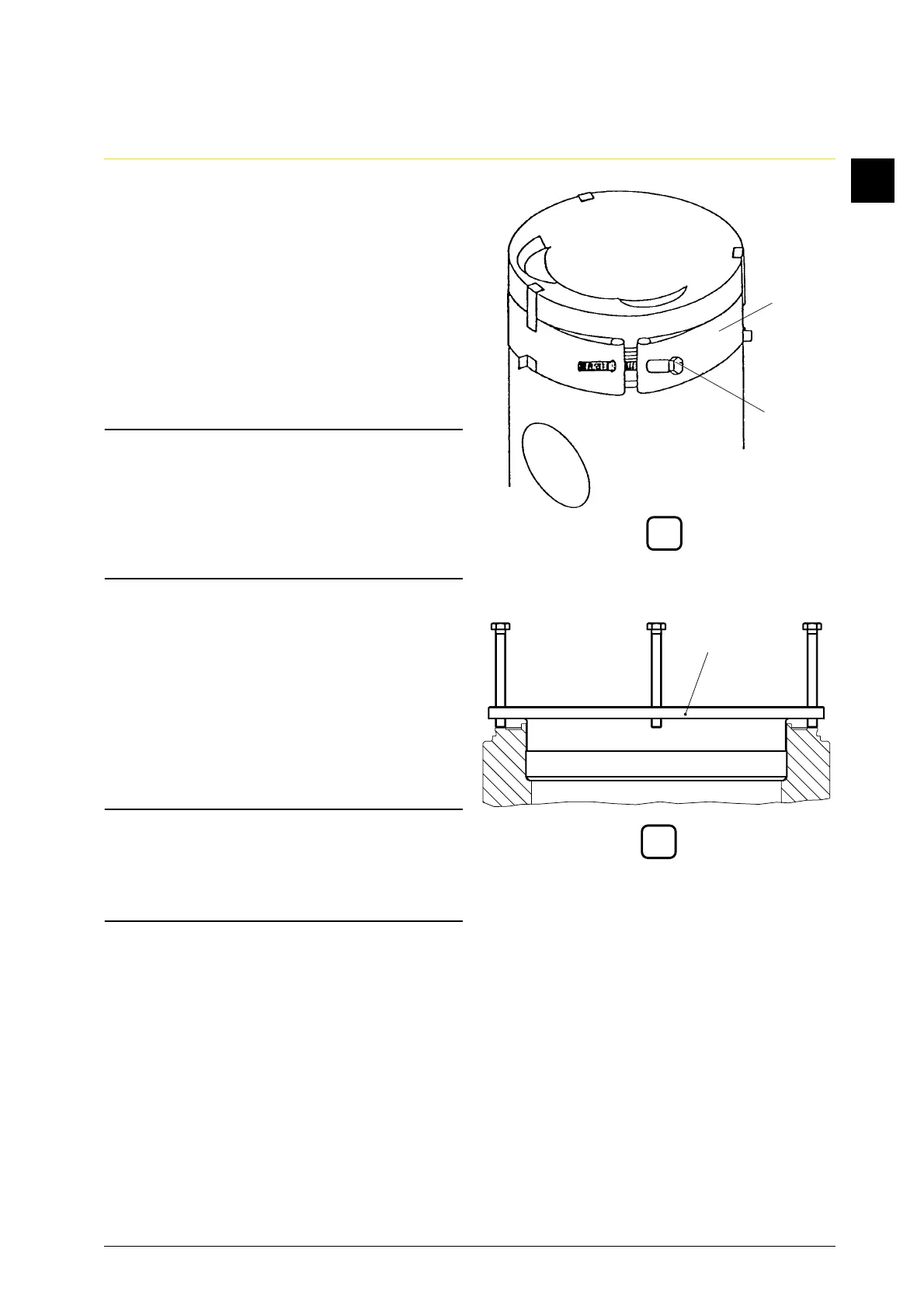

7. Mount the piston assembly ring (fig. 2/

W3).

8. Mount the piston mounting/extraction

device (fig. 3/W1).

Attention:

Turn the crank pin to a favourable

installation position. The bottom end

must not knock against the crank pin

when being lowered.

9. Attach the piston (3) to the crane and raise it.

10. Carefully insert the bottom end in the cylinder liner with the cylinder number mark towards

the control side and lower the piston exactly in the cylinder axis so that the bottom end

does not jam in the cylinder liner.

11. Let the piston insertion device (fig. 1/W4) lie flush on the piston assembly ring (fig. 2/W3)

and carefully lower the piston further guiding the bottom end over the crank pin by hand.

1

10

W4

•

•

2

W3

Loading...

Loading...