Duplex Fuel Preliminary Filter

Maintenance / Cleaning

A5.05. 07.12.02.02

750

M20/M32/M282/M332C/M452/M453C/M551/M552C/M601/M601C

en / 05.06.2000 IB022107 2/2

07

Ĺ

2.5 Put the filter element in a suitable cleansing liquid (e. g. “Filterclean” from Vecom).

The cleansing liquid must only reach up to the bottom edge of the top frame of the filter

element so that no contaminated liquid can enter into the clean space of the element.

Soaking time as required by the supplier of the cleanser, but maximum 8 hours.

2.6 Take the filter element out of the cleansing liquid. When withdrawing the internal and

unprotected straniners of an element, make sure that the gauze is not damaged.

Inspect all strainers on the inside and outside, because the individual strainers are connec-

ted in parallel, and damage on only one strainer means malfunction ot the whole element.

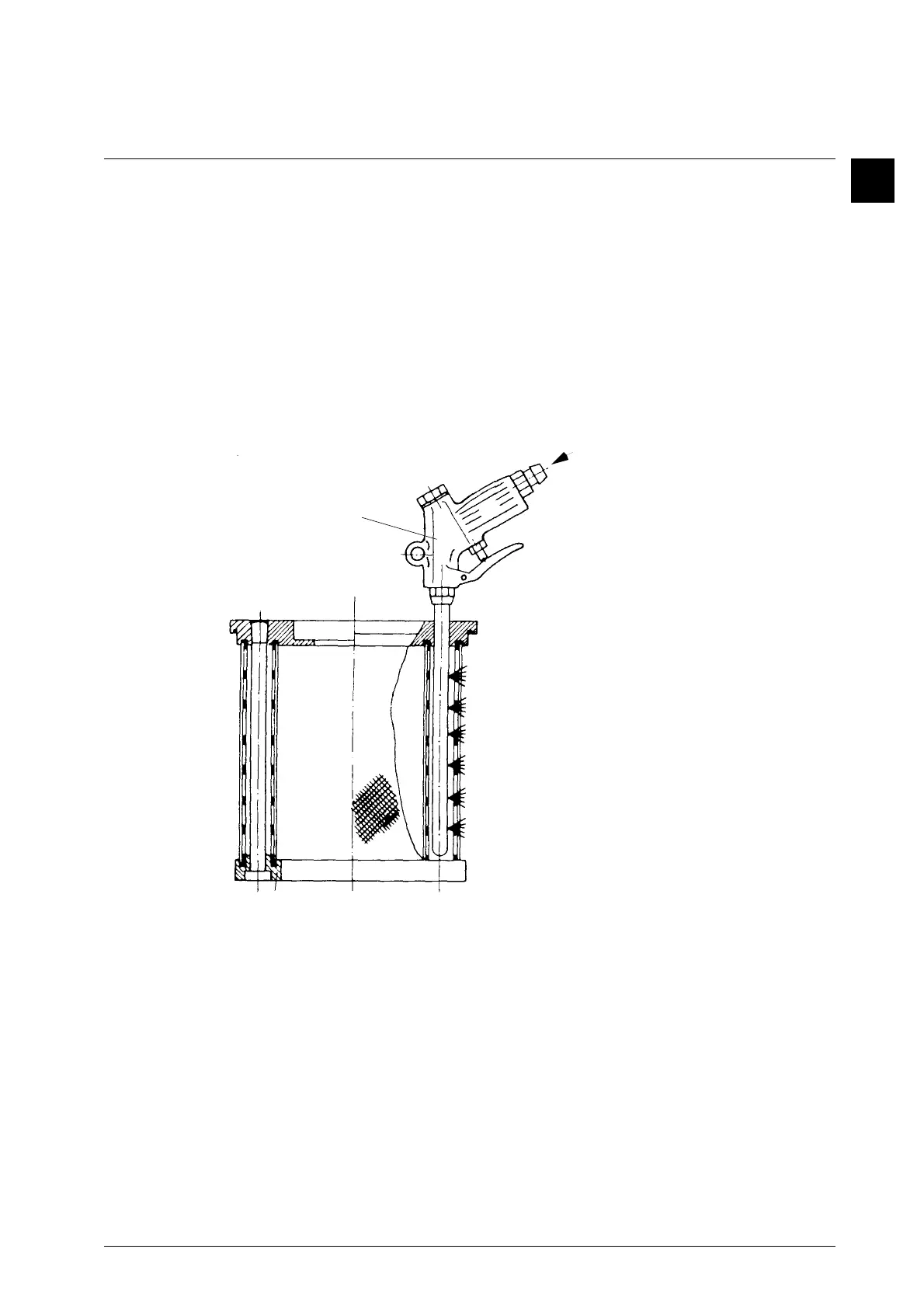

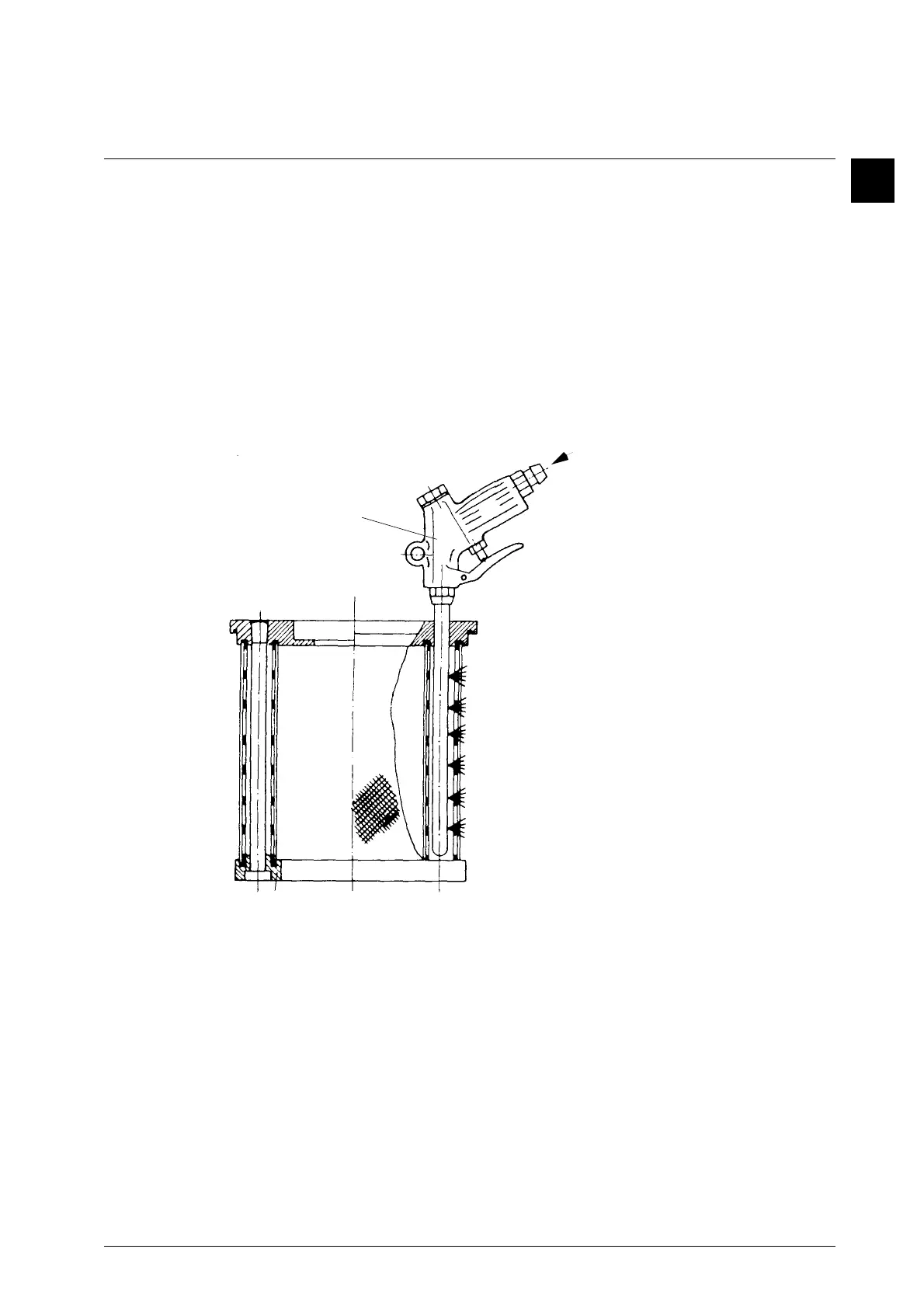

2.7 Blow compressed air through each strainer with the pistol (Fig. 2/W1) and clean the inside

and outside with a soft brush.

2.8 Flush the strainers with clean gas oil. Make sure that no contaminated gas oil can enter

into the clean space from the top.

2.9 Put a strong light behind the gauze and check the cleaning operation. Repeat it if necessary.

2.10 Telescope the strainers again and fit them in the filter chamber.

2.11 Fit the cover (check the gasket and renew it if necessary).

2.12 Fill the filter chamber and vent it (see the plate on the filter cover).

p = 2 ... 10 bar

W1

Fig. 2

Loading...

Loading...