Lubricating Oil/Cooling Water Thermostat

Maintenance / Checking

A5.05. 11.06.01.01

7500

M20-M601C

en / 31.05.2000 IB021750 1/2

11

Ĺ

See also:

Spare parts list: B1.05.11.1.7837

Time requirement: 1 Pers./ 1,00 h

Personnel qualification: skilled engine hand

---------------------------------------------------------------------------------------------------------------------

Operating medium: Heavy fuel and distillate fuel

Maintenance:

Disassembly of lubricating oil/cooling water thermostat,

making a funcional check of thermostatic element every 7,500 h

Note:

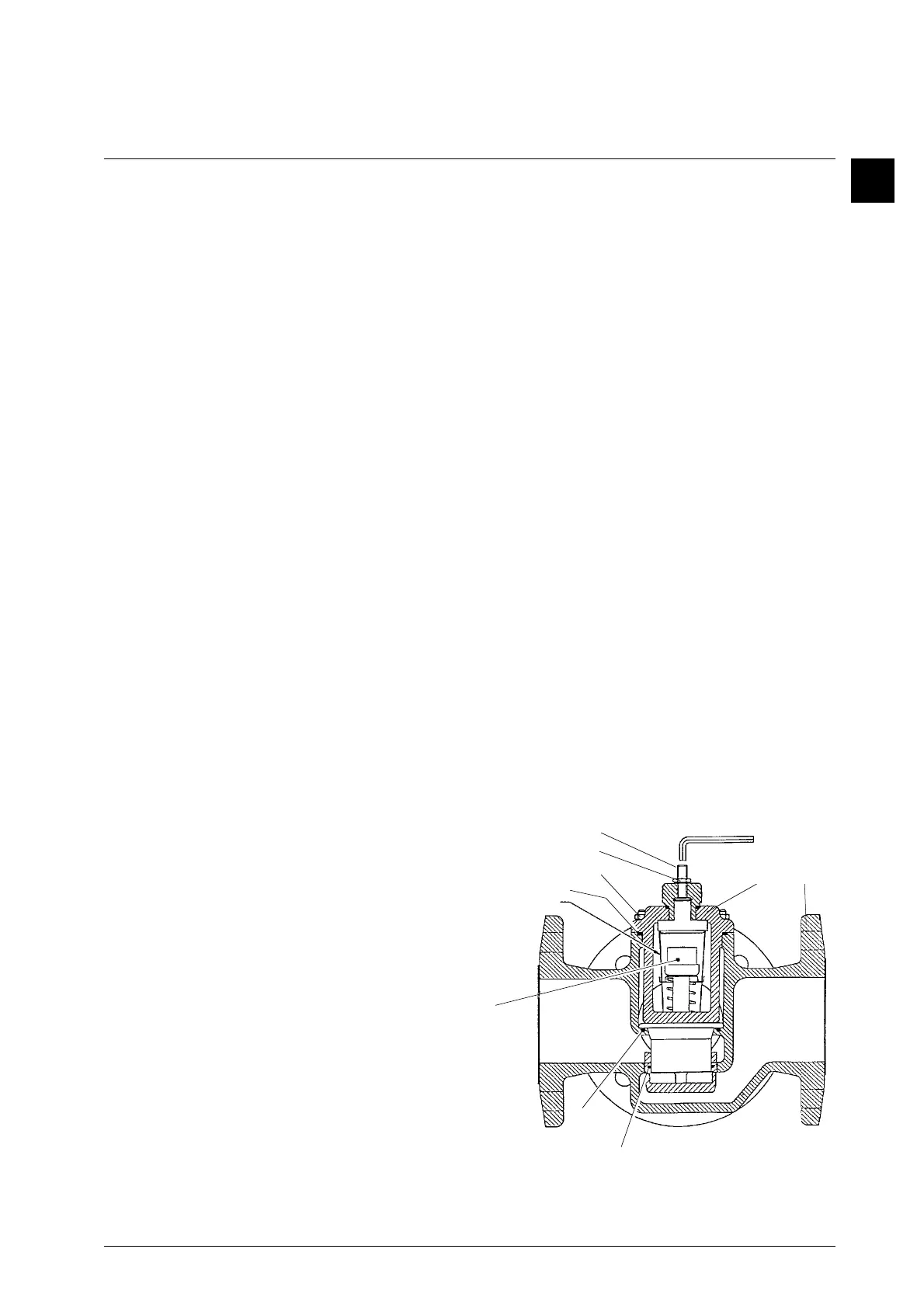

The thermostatic elements (Fig. 1/5) are adjusted by the manufacturer to the required

temperature. Modification of the adjustment or repair is impossible. Defective elements

must be exchanged completely.

Controlling the thermostatic elements in case of failure is enabled by a manual control

facility. Hereto slacken counter nut (3) and turn set screw (4) clockwisely in order to get

a lower temperature. After setting counter again.

The cooling line is fully opened and the bypass closed when the set screw (4) flushes

with the surface of the counternut (3).

This setting procedure may only be carried out if the thermostat fails.

With mounting a new thermostat, the set screw (4) must be set to its initial position by

the nut (3).

Sequence of operations:

1. Disassembly

1.1 Drain lubricating oil/cooling water lines.

1.2 Unscrew hexagon nuts (2) of housing

cover (6).

1.3 Remove cover (6) with O-ring (1).

1.4 Turn out thermostatic element (5)

from valve housing (7).

1.5 Wash parts in gas oil and blow them

clean.

1.6 Wipe clean thermostat housing with

lint-free cloth and check for corrosion

and deposits.

4

3

2

1

5

9

8

•

•

6

7

XX

Fig. 1

Loading...

Loading...