GROVE 5-19

CD3340B/YB4411 MAINTENANCE

Published 04/07/2015 Control # 569-00

The boom retract chain is lubricated through the access

holes in the boom. Align the holes to expose sections of the

boom chain. Each section must be lubricated as directed

below.

NOTE: Use a good grade of spray chain lubricant. If none

is available, use preheated oil (15° to 37°C [60° to

100°F]) to provide a better penetration of oil to the

chain joints.

Apply ample lubricant to each pin, between the inner and

outer side plates and between the inner side plates and

roller. DO NOT, under any circumstances apply grease

lubricant to the chain. Grease will not penetrate to the pin

bearings. Lack of lubricant in the pin bearings is usually

indicated by squealing or groaning sounds when the boom is

extended or retracted.

NOTE: Under normal operating conditions, especially in

dusty environments, lubricated chains will

accumulate a paste-like buildup of grime. This

buildup should never be permitted to accumulate

sufficiently to seal off the clearances, thereby

restricting the lubricant to the bearing surfaces.

Whenever the buildup is excessive, the buildup

must be removed by cleaning and the chain

immediately lubricated. DO NOT steam clean or

use degreasers; use a suitable solvent.

100 Hours of Operation

NOTE: You must read and understand the warnings and

basic safety rules, found in Section 1 of this

manual, before performing any operation or

maintenance procedures.

For additional engine maintenance guidelines, see

the engine manual furnished with this crane.

Check Wheel Nut Torque

Check the torque on the wheel nuts in a crisscross pattern.

Wheel torque should be 225 lb-ft (302Nm).

Inspect the Fan Belts

Keep the engine and accessory belts properly tensioned for

maximum engine performance and fuel economy. Proper

belt tension minimizes slippage and increases belt life.

Belts that are too loose see excessive vibration and

increased wear. Belts that are too tight produce wear on the

belts and the bearings of the pulleys it travels around.

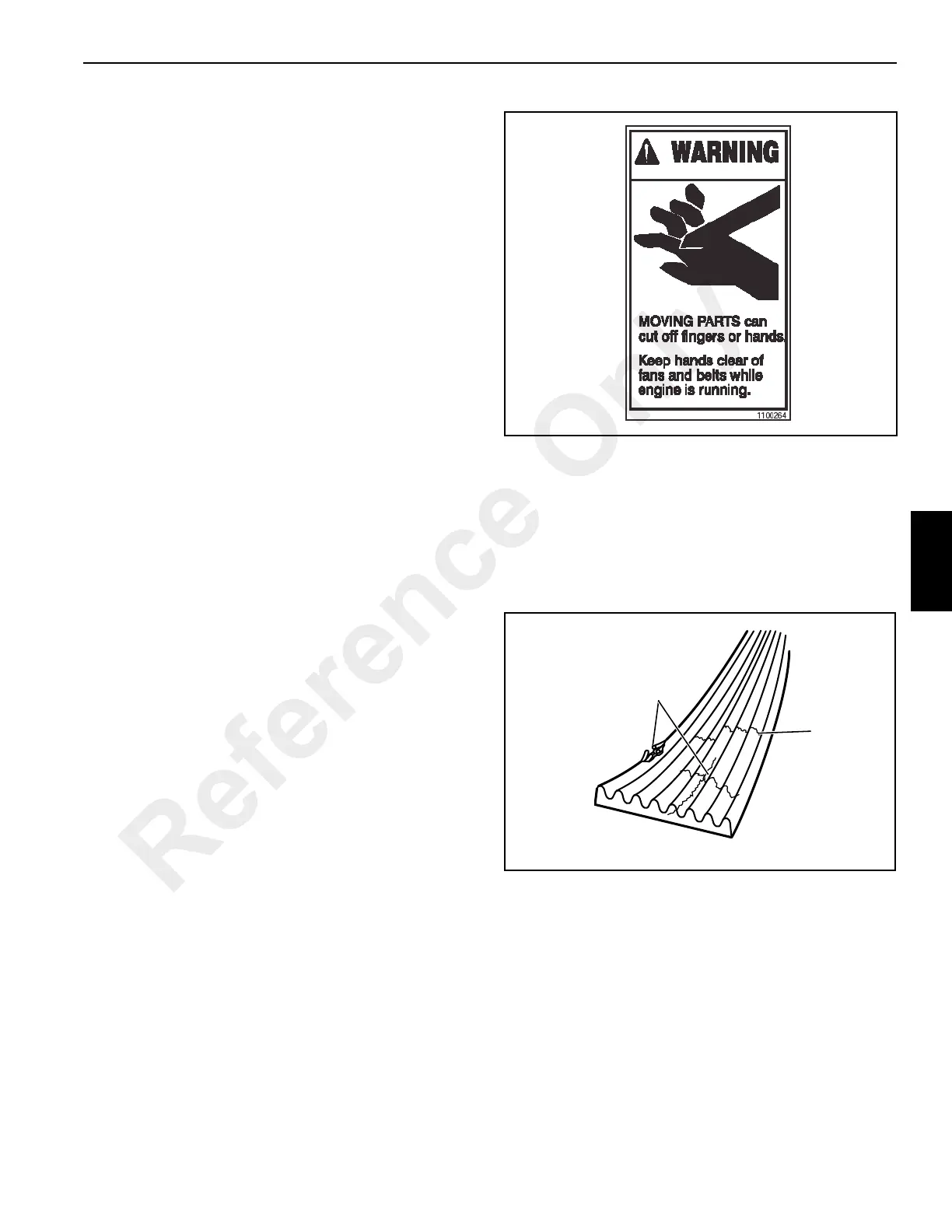

Check ribbed belts for intersecting cracks. Cracks across the

belt are acceptable. Cracks along the length of a ribbed belt

are not acceptable. Ribbed belts with cracks along their

length or intersecting cracks should be replaced. See

Figure 5-31.

a0019

FIGURE 5-31

Replace

Belt

Lengthwise Cracks, Intersecting

Cracks, or Belt Damage NOT OK.

Cracks Across

Width OK

Reference Only

Loading...

Loading...