GROVE 5-35

CD3340B/YB4411 MAINTENANCE

Published 04/07/2015 Control # 569-00

16. Fill the hydraulic tank with Mobil #424 hydraulic oil to the

bottom of fill stainer or to sight gauge.

17. After the tank is filled, start the engine and operate each

function until all the cylinders and lines are filled.

18. Fully retract and lower the boom and retract the

outriggers. Check the hydraulic oil level. Oil must be to

the bottom of the fill strainer. Add hydraulic oil if

necessary.

19. Visually check for leaks.

Replace the Hydraulic Oil Filter

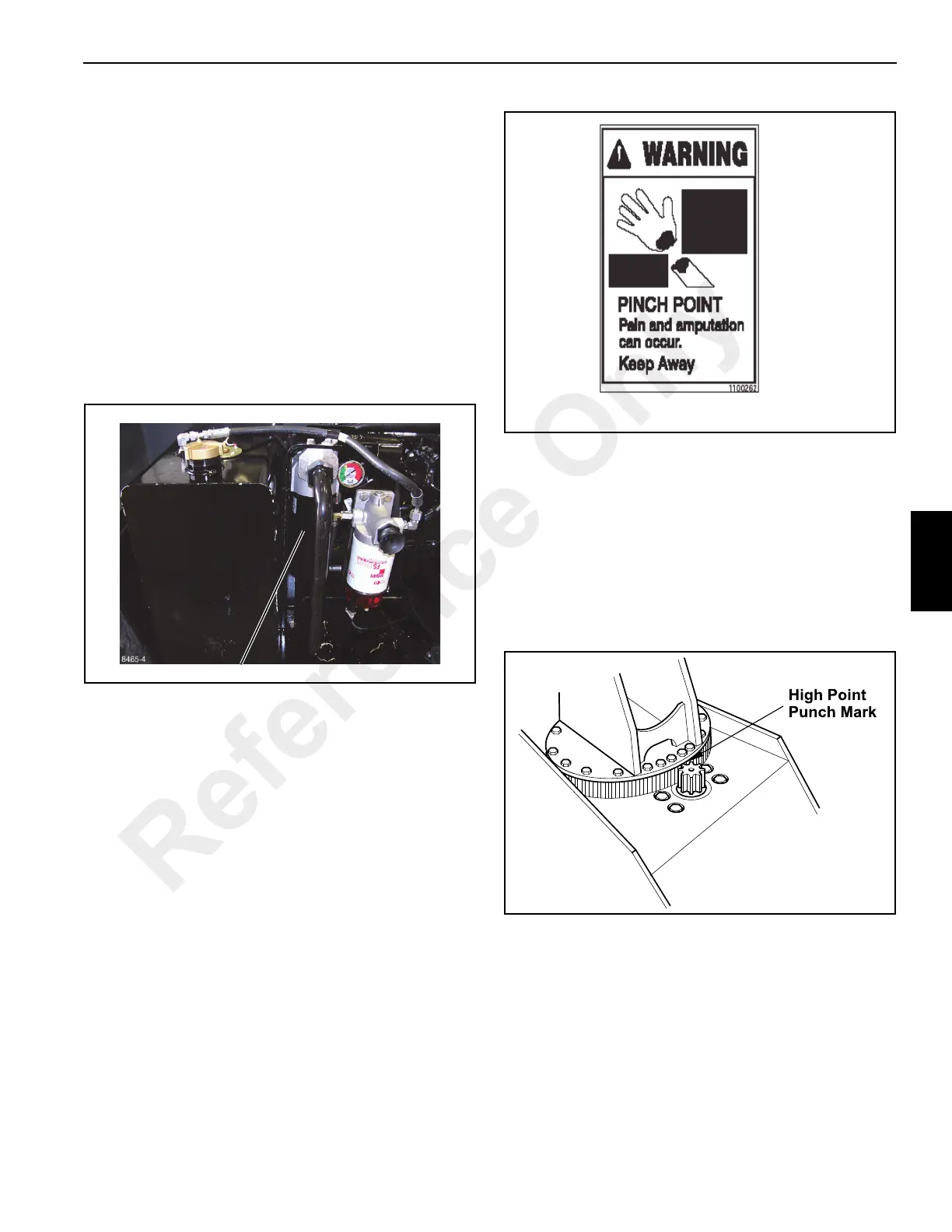

1. Engage the parking brake and shut off the engine.

2. Remove the side panel to expose the hydraulic

compartment and the hydraulic filter (Figure 5-76).

3. Remove the filter:

a. Using a filter wrench, turn the filter counterclockwise

to loosen and remove the filter. Properly discard the

removed filter.

b. Clean the mounting surface on the filter head for the

filter seat.

4. Install the filter:

a. Apply a small amount of clean hydraulic oil to the

gasket of the new hydraulic filter. Install the filter to

the filter head by turning it clockwise until the filter

gasket makes contact. Then, tighten the filter 1/2 to

3/4 turn to achieve a tight seal.

b. Start the engine and check for leaks around the

filter.

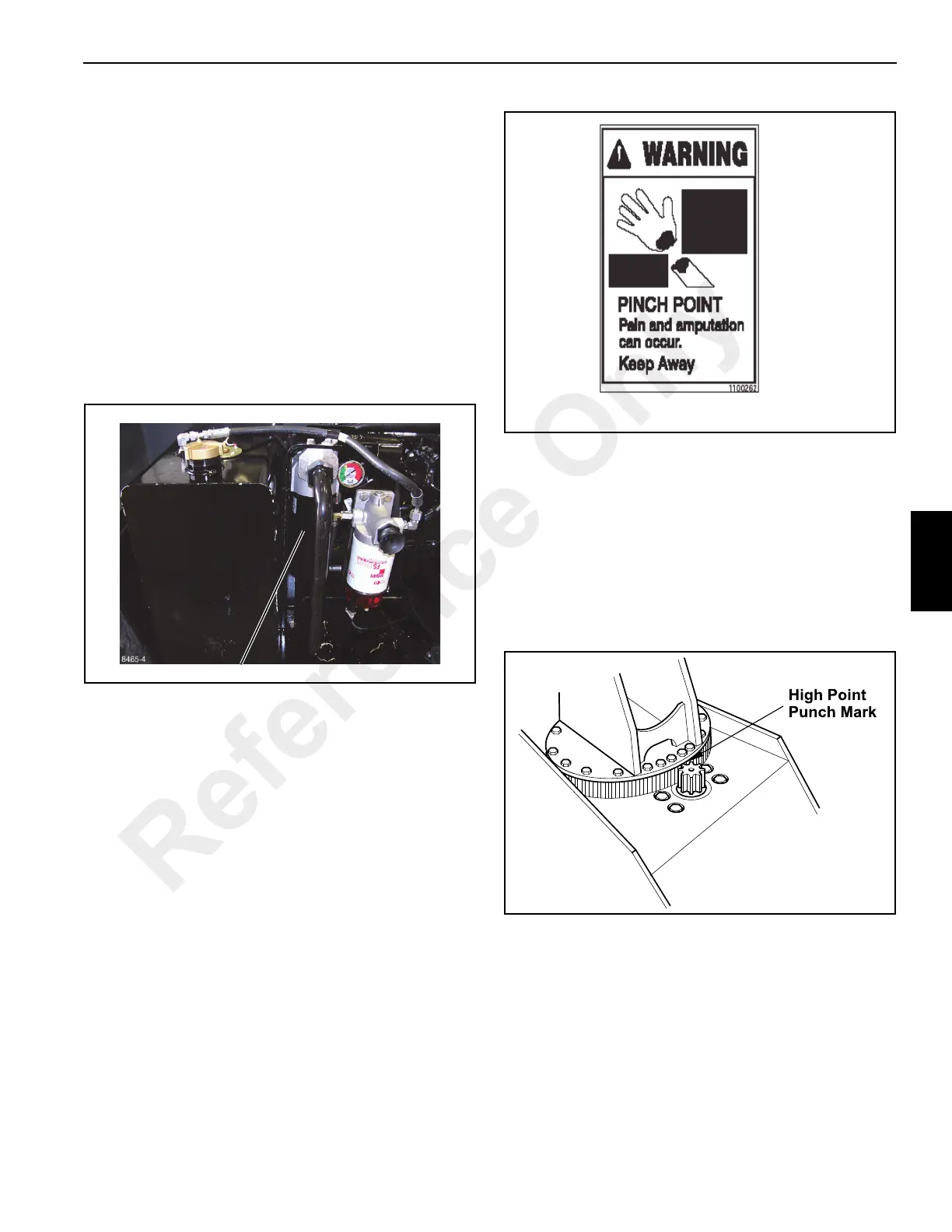

Check Swing Gear/Pinion Backlash

1. Remove the cover to expose the swing pinion and ring

gear.

• Rotating gears can cause injury. Keep hand clear of

rotating pinion and gear while the mast is rotating.

2. Start the engine and rotate the mast until the high point

on the swing gear is in alignment with the pinion. The

high point is punch-marked on the edge of the mast

base plate (Figure 5-77).

3. Using a feeler gauge, check the backlash between the

gear and pinion. There should be no clearance between

the swing gear tooth and the pinion tooth. If there is any

clearance, adjust the backlash. See Section 11.

2000 Hours Of Operation/Yearly

NOTE: You must read and understand the warnings and

basic safety rules, found in Safety Practices page

2-1 of this manual, before performing any operation

or maintenance procedures.

For additional engine maintenance guidelines, see

the engine manual furnished with this crane.

8465-4

FIGURE 5-76

Hydraulic Filter

Reference Only

Loading...

Loading...