HYDRAULIC SYSTEM CD3340B/YB4411

4-36

Published 04/07/2015 Control # 569-00

Installation

1. If complete valve assembly is being installed, put the

valve assembly in position and secure it with four

capscrews, washers and nuts. Connect the hydraulic

lines to the manifold block and connect the wire leads to

the solenoids.

2. If a valve section is being installed, place the valve

section in position and fasten with four socket head

capscrews. Connect the wire leads.

3. Connect the battery cables to the battery. Positive cable

first; negative cable second.

4. Start the engine and check outriggers for correct

operation. Check for leaks and add hydraulic oil to the

hydraulic tank, if necessary.

Swing Motor

Removal

1. Shut off the engine, set the parking brake and place

chock blocks at each wheel. Before disconnecting any

lines or hoses from the swing motor, let the system bleed

down for approximately 10 minutes after shutting off the

engine. Even then, disconnect the hose or line slowly to

release any pressure that still might be in the circuit.

NOTE: The swing motor can only be reached from under

the machine. Shut off the engine, set the parking

brake and remove the ignition key. Block all tires.

2. Before disconnecting the hydraulic lines, clean the port

area of the swing motor thoroughly. Disconnect the

hydraulic lines from the swing motor. Put caps and plugs

on the hoses and ports to keep dirt out.

3. Remove the two mounting socket head capscrews and

lockwashers from the swing motor. Remove the swing

motor and gasket. Discard the gasket.

Disassembly

NOTE: Cleanliness is extremely important when repairing

the swing motor. Work in a clean area. Plug the

ports then use a wire brush to remove foreign

material and debris from around the external joints

of the motor. Check the shaft and key slot, remove

all nicks, burrs or sharp edges that might damage

seals during installation. Before starting the

disassembly procedures, drain any remaining oil

from inside the motor.

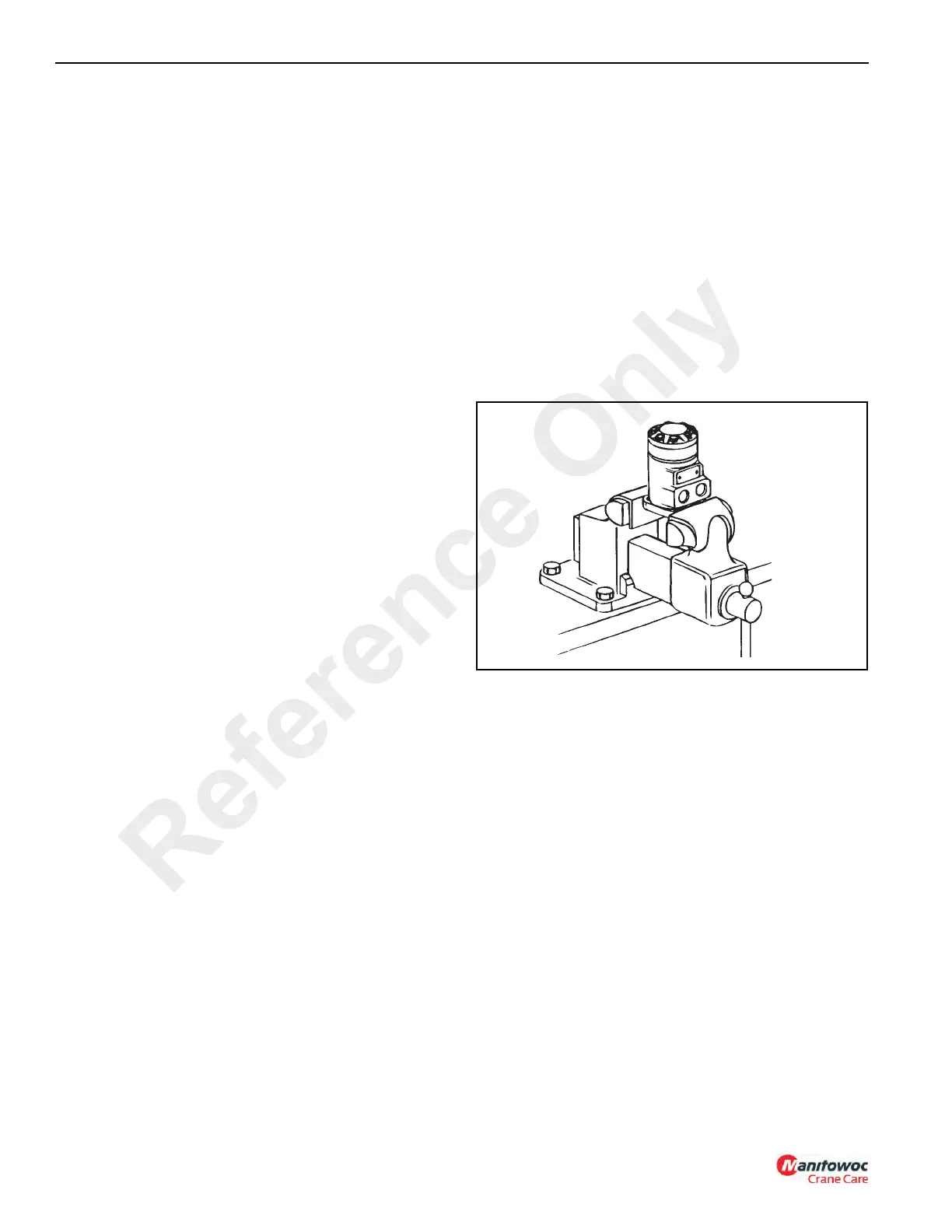

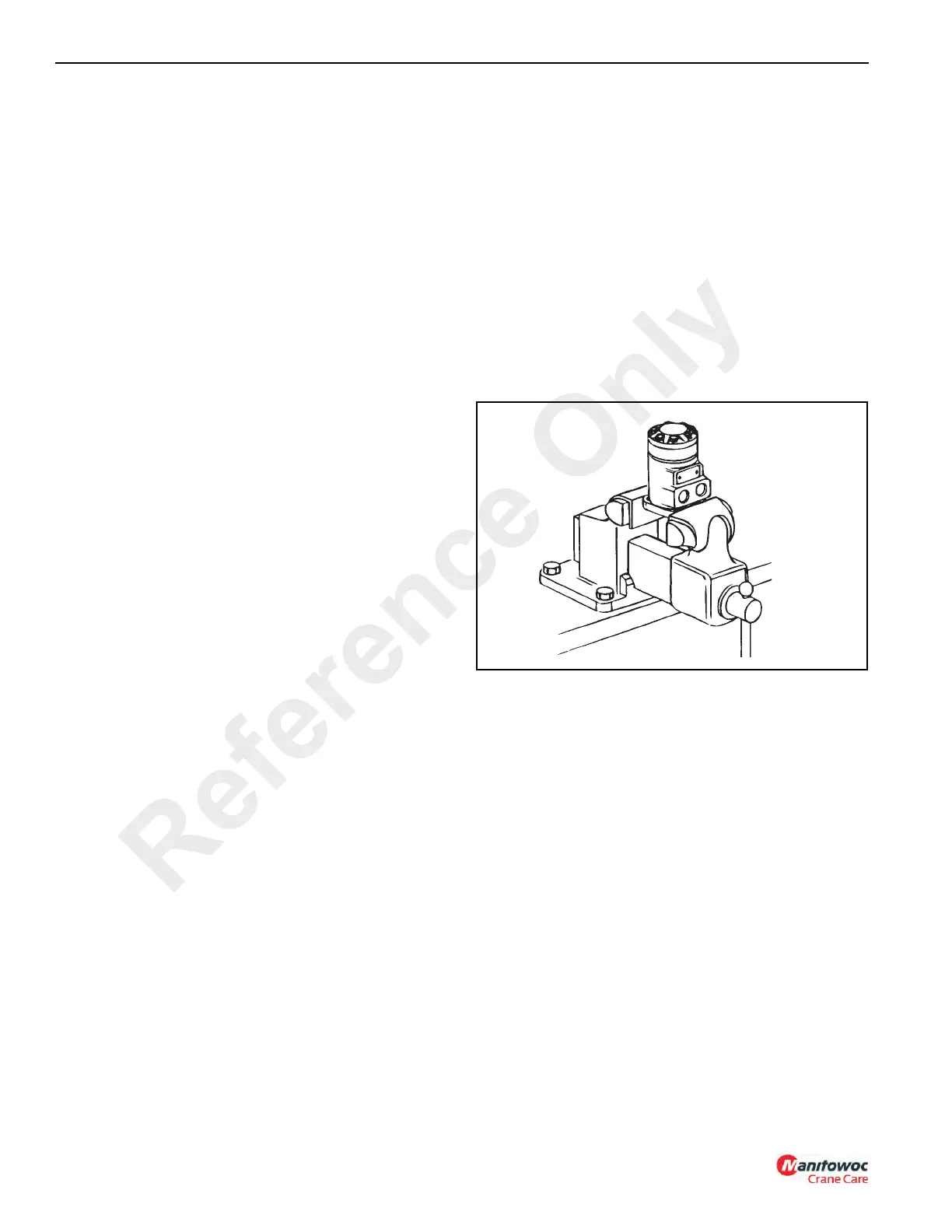

1. Place the motor in a vice and clamp across the edges of

the flange (Figure 4-23) with the output shaft facing

down. When clamping use protective devices on the

jaws, such as soft jaws, pieces of rubber or wood.

NOTE: Although not all drawings show the motor in a vice,

it is recommended that you keep the motor in the

vice during disassembly and assembly. Follow the

clamping procedure explained in Step 1.

2. Remove seven capscrews (19, Figure 4-24) and seal

washers (18).

3. Remove end cap (17). Remove and discard seal (13)

from the end cap.

4. Remove gerotor (16). Remove and discard seal (13)

from the gerotor.

5. Remove drive shaft (14).

Reference Only

Loading...

Loading...