GROVE 4-37

CD3340B/YB4411 HYDRAULIC SYSTEM

Published 04/07/2015 Control # 569-00

6. Remove spacer plate (15).

7. Remove seal (13) from housing (10).

8. Remove output shaft (9) from housing (10).

9. Remove needle thrust bearing (8) from shaft or housing.

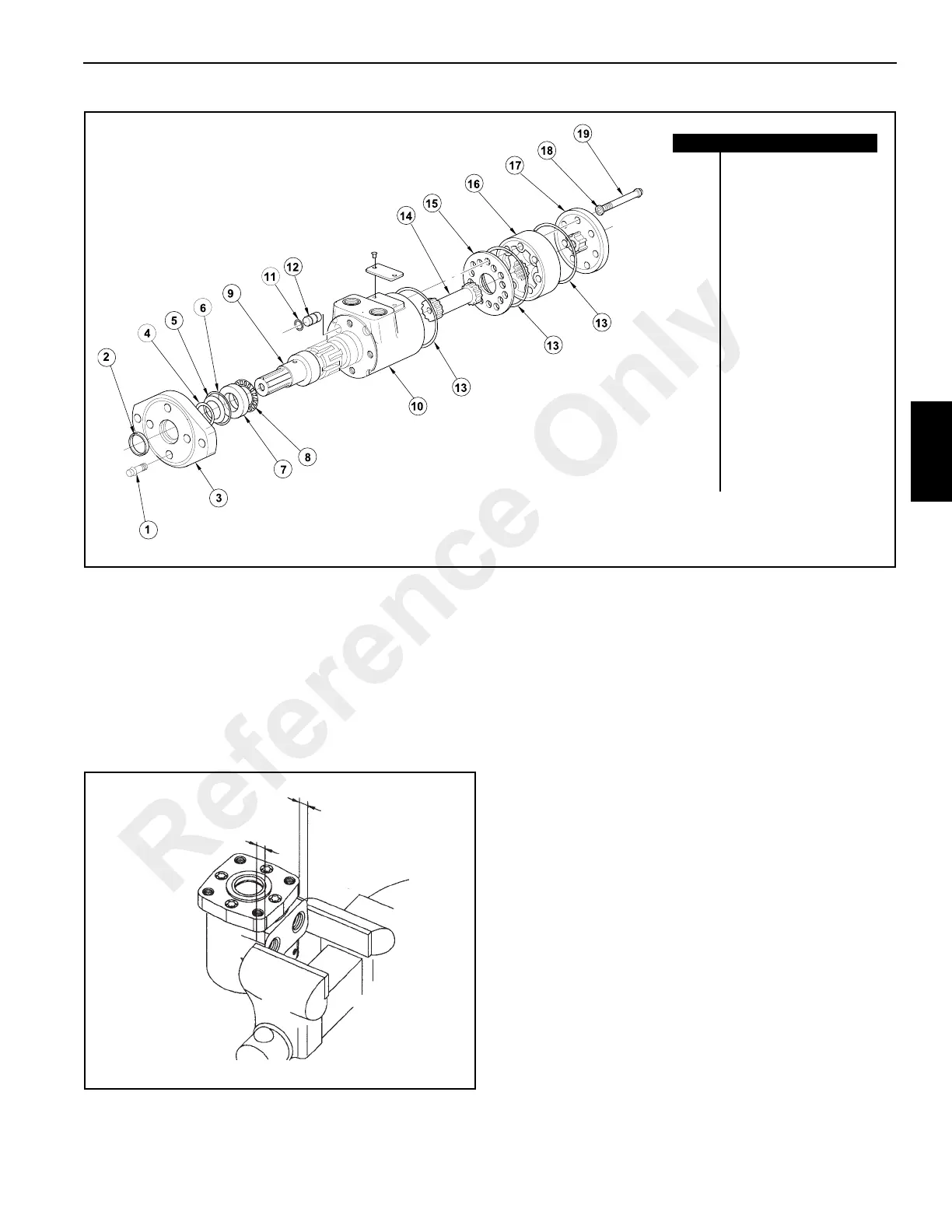

10. Reposition the motor in the vice. Clamp across ports as

shown in Figure 4-25. DO NOT clamp on housing.

Excessive clamping pressure on side of housing causes

distortion.

11. Remove four capscrews (1) from mounting flange (3).

These screws were installed with Loctite to hold them in

place.

The screws will require 35 - 45 Nm (300 - 400 lb-in) of

torque to break loose and 11 Nm (100 lb-in) torque to

remove. Do not use an impact wrench on the screws.

This could result in rounded heads or broken sockets.

NOTE: If a torque higher than given above is required to

break the capscrews loose, apply heat according to

the following:

When heated, Loctite partially melts. This reduces

the torque required to remove screw. Use a small

flame propane torch to heat a small area of the

housing where the screws enter. See Figure 4-26.

Be careful not to overheat the housing and

damage the motor. Gradually apply torque to the

capscrew with a socket wrench as heat is applied

for 8 to 10 seconds. As soon as the screw breaks

loose, remove the heat from the housing. Continue

turning the screw until it is completely removed.

Repeat for other capscrews.

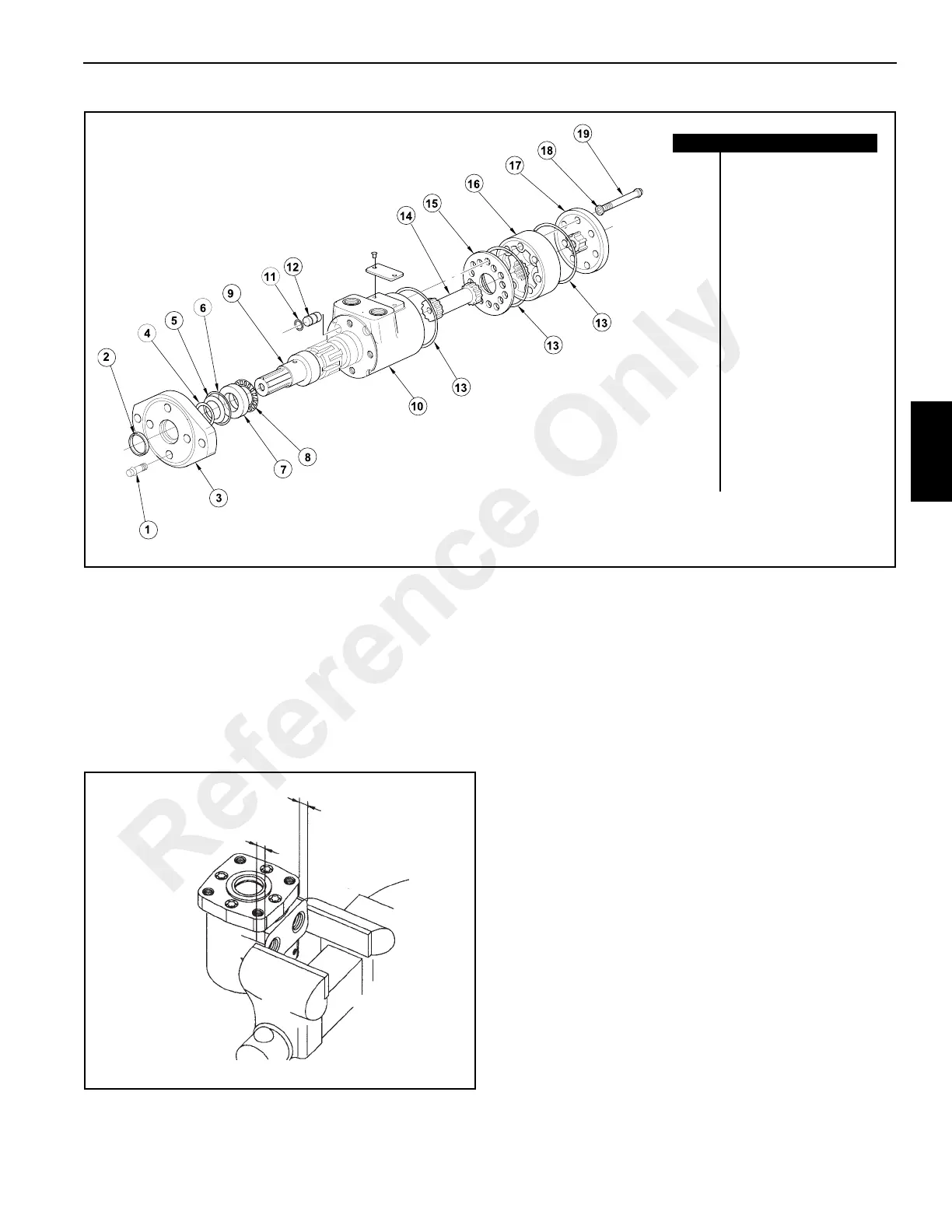

FIGURE 4-24

Item Description

1Screw (4)

2 Exclusion Seal

3 Mounting Flange

4 Backup Ring*

5 Shaft Pressure Seal *

6 Seal*

7 Bearing Race

8 Thrust Needle Bearing

9 Output Shaft

10 Housing

11 O-ring

12 Plug

13 Seal (3)*

14 Drive Shaft

15 Spacer Plate

16 Gerotor Set

17 End Cap

18 Seal Washer (7)*

19 Screw (7)

* Included In Seal Kit

a0949

FIGURE 4-25

a0764

1/2” (13 mm)

1/2” (13 mm)

Reference Only

Loading...

Loading...