HYDRAULIC SYSTEM CD3340B/YB4411

4-38

Published 04/07/2015 Control # 569-00

12. Carefully remove flange (3, Figure 4-24) from housing

(10).

13. Exclusion seal (2), backup ring (4), pressure seal (5) and

seal (6) will come off with flange (3). Use the seal

removal tool shown in exclusion and pressure seals.

14. A metal plug (12, Figure 4-24), with O-ring (11), plugs a

machined hole in the housing. It is not necessary to

remove the plug and replace the O-ring unless leakage

occurs around the plug. To remove the plug, insert a 5

mm (0.187 in) hex key through the port opening and

push it out.

Inspection/Cleaning

Check all mating surfaces. Replace any parts with scratches

or burrs that could cause leakage or damage. Clean all metal

parts in a suitable solvent. Blow dry with air. Do not wipe

parts with a cloth or paper towels, because lint or other

matter could get into the hydraulic system and cause

damage.

Check around the key slot and chamfered area of the shaft

for burrs, nicks or sharp edges that could damage seals

during assembly. Remove nicks or burrs with a hard smooth

stone. Do not file or grind motor parts.

NOTE: Lubricate all seals with petroleum jelly. Use new

seals when assembling the motor. DO NOT

stretch the seals before installing them.

Cleanliness is extremely important in the successful

application of Loctite. Before Loctite can be applied, the parts

should be cleaned as follows:

NOTE: Fully cured Loctite resists most solvents, oils

gasoline and kerosene and is not affected by

cleaning operations. It is not necessary to remove

cured Loctite that is securely bonded in tapped

holes; however, any loose particles of cured Loctite

should be removed.

1. Wash the housing with a suitable solvent to remove oil,

grease and debris. Pay particular attention to the four

tapped holes on the flange end.

2. Blow dry with compressed air. Clean and dry the tapped

holes.

3. Wire brush the screw threads to removed cured Loctite

and other debris. Discard any screws that have

damaged threads or rounded heads.

4. Wash the screws with a non-petroleum base solvent.

Blow dry with compressed air.

Assembly

Shaft End

1. If plug (12, Figure 4-24) was removed, lubricate the new

O-ring (11) and install on the plug. The plug has two O-

ring grooves, but requires only one O-ring in the groove

closest to the end of the plug. Push the plug into the

housing (10) until it is flush with the housing. Be careful

not to damage the O-ring.

2. Lubricate output shaft (9) with hydraulic oil (Figure 4-29)

and install the shaft into housing (10, Figure 4-24).

NOTE: Do not permit oil to get into the four tapped holes of

the housing (10).

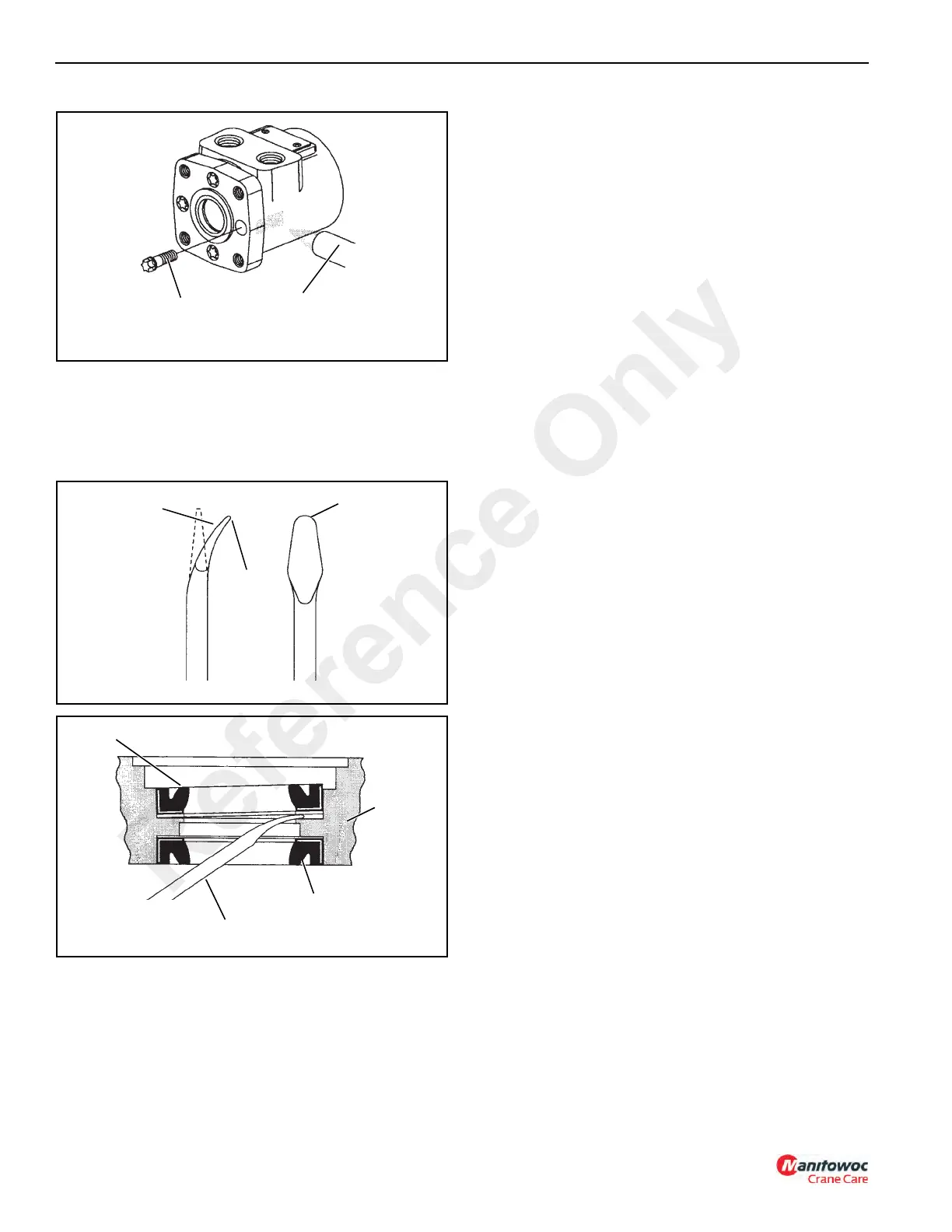

FIGURE 4-26

a0765

Capscrew (4)

Heat With a Propane

Torch To Melt Loctite

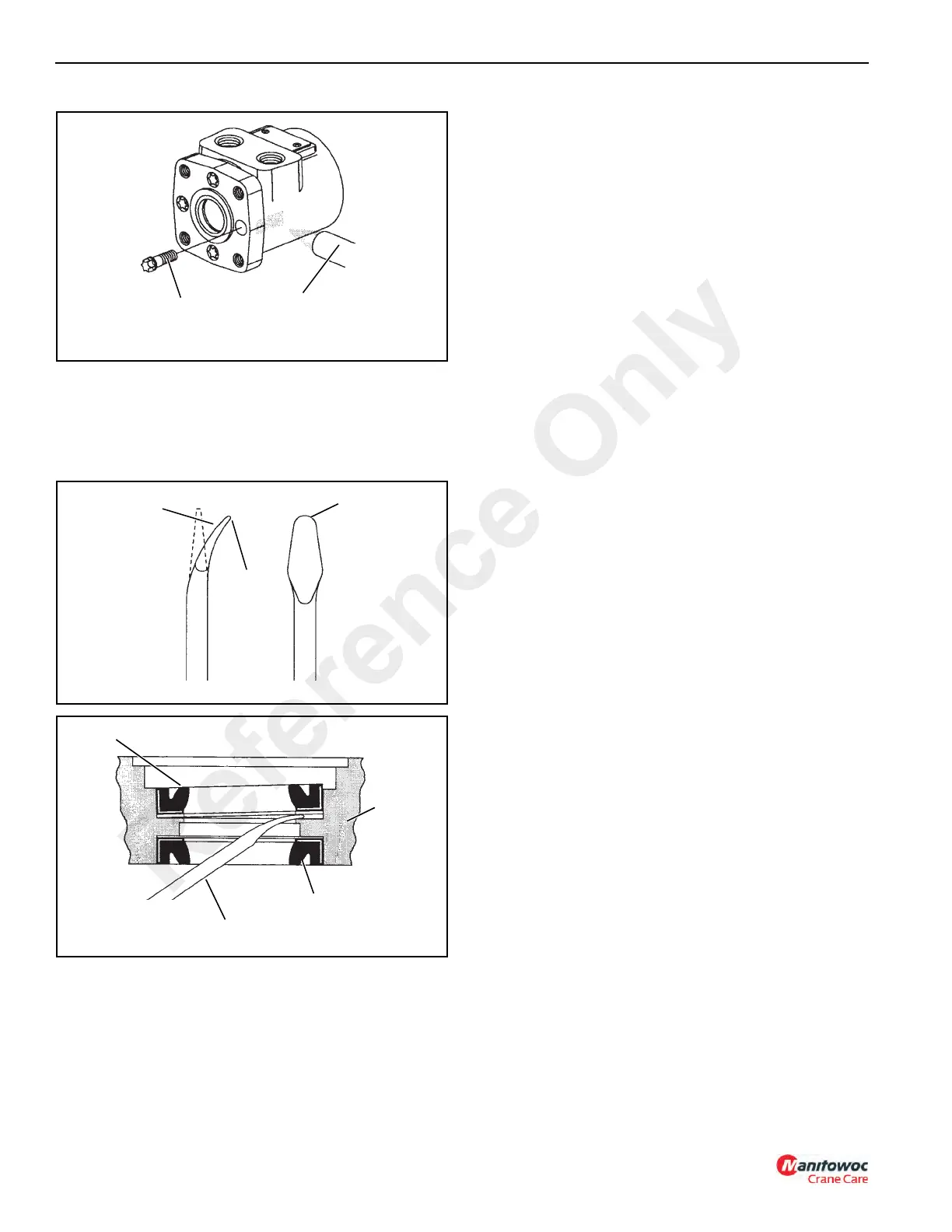

FIGURE 4-27

a0766

Modify

Screwdriver as

Shown. Remove

All Burrs

Bend Tip

Radius on

End

Radius

FIGURE 4-28

a0767

Pressure Seal

Exclusion

Seal

Mounting

Flange

Seal Tool

Reference Only

Loading...

Loading...