INTRODUCTION CD3340B/YB4411

1-14

Published 04/07/2015 Control # 569-00

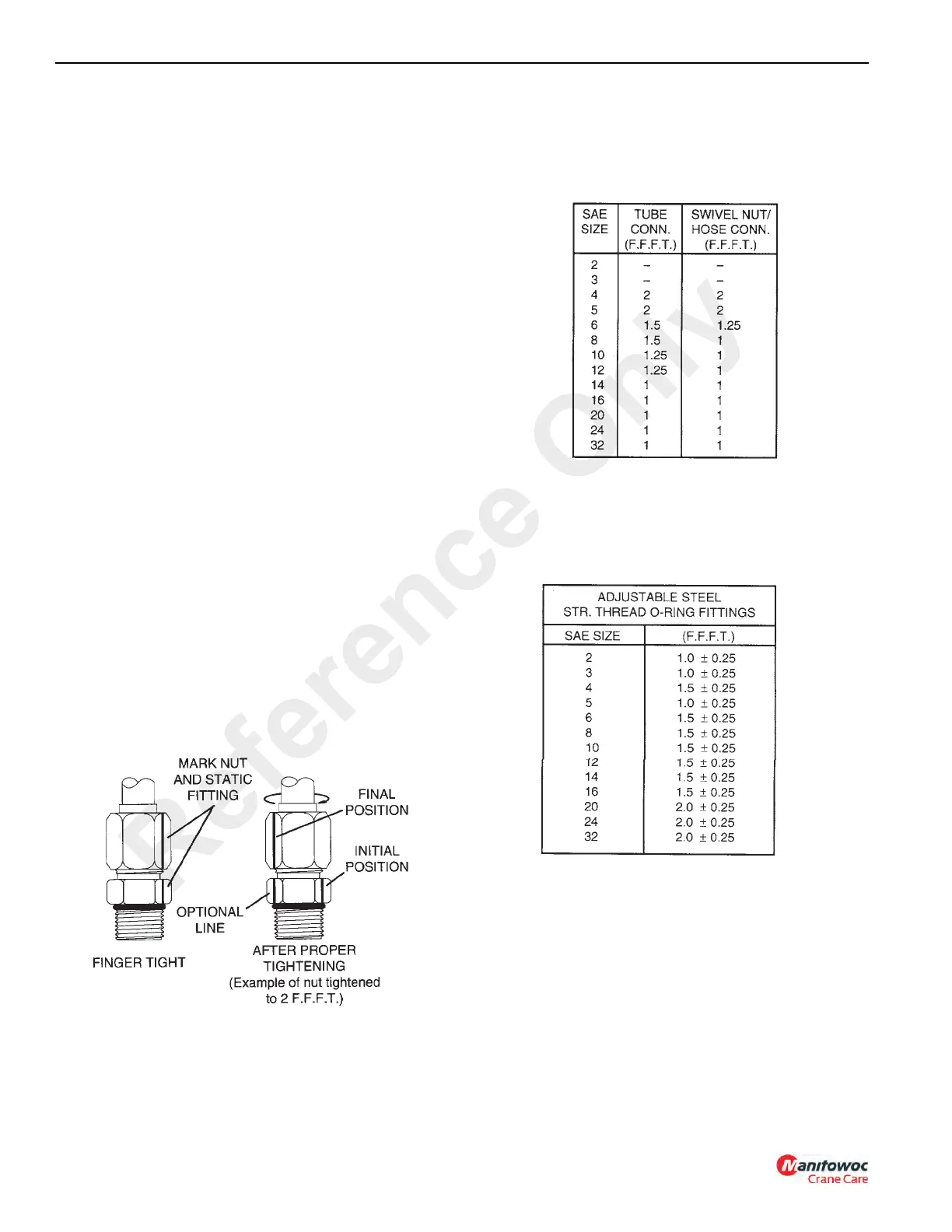

HYDRAULIC FITTING F.F.F.T. METHOD

(FLATS FROM FINGER TIGHT)

Manitowoc, Inc. recommends that the F.F.F.T. tightening

method described here be used when assembling all

hydraulic fittings. This method will minimize the risk of fitting

damage or failure due to under or overtightening.

It will also reduce the chance of a leaky connection which is

caused normally by different plating combinations of fittings.

This method is particularly useful when plating type of fitting

is unknown and during maintenance or repair when a joint

may be oily.

Follow these steps when tightening all fitting connections:

1. Make sure both threads and sealing surfaces are free of

burrs, nicks, scratches or any foreign particles.

2. Align tube or hose to the mating fitting and check to see

that the flare seats properly on the nose of the fitting.

3. Finger tighten the nut onto the fitting. If necessary, a

wrench should be used to seat the nut snugly against

the fitting. This is considered the FINGER TIGHT

condition.

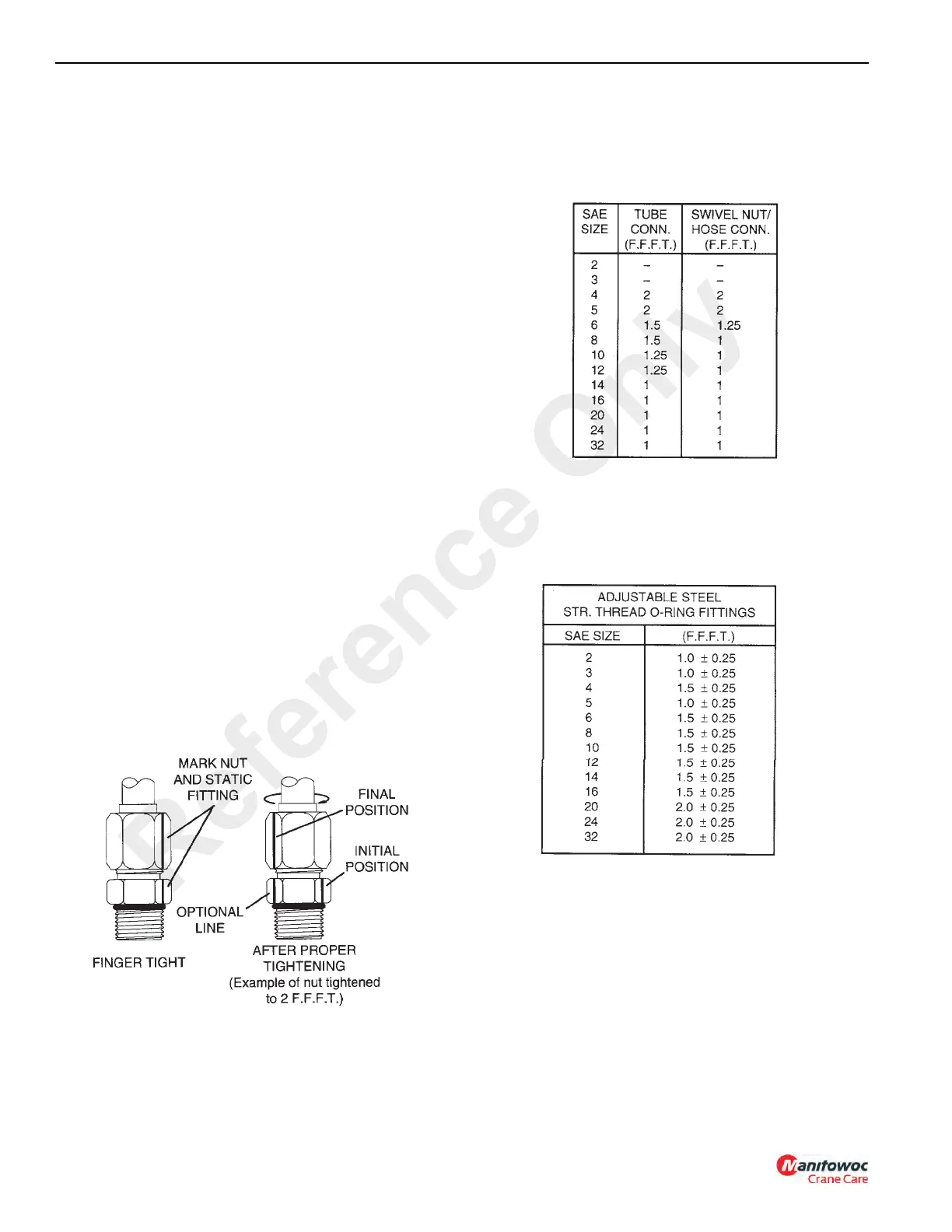

4. Using a permanent-type ink marker, make a mark on

one of the flats of the nut and continue it onto the hex of

the static fitting or port (Figure 1-7.)

5. Tighten the joint by the number of flats (F.F.F.T.) as

specified in Table 1-11 and Table 1-12 for size and type

of fitting.

6. (Optional for future tightening of the same connection.)

Extend the line from the nut at its new location onto the

hex of the static fitting or port (Figure 1-7).

37°Flared Steel Fitting - Tube or Hose to

Fitting (Table 1-11)

See Hydraulic Fitting F.F.F.T. Method in this section.

Adjustable Straight Thread O-ring Fitting -

Fitting to Port (Table 1-6)

1. Inspect both mating parts for burrs, nicks, scratches, or

foreign particles.

2. Lubricate O-ring with a light coat of clean oil

(Figure 1-8 A).

3. Back off locknut as far as possible (Figure 1-8 A).

4. Screw fitting into port by hand until the backup washer

contacts face of port and is pushed all the way towards

the locknut (Figure 1-8 B & C).

5. To orientate the fitting, unscrew the fitting the required

amount, but not more than one full turn (Figure 1-8 D).

Reference Only

Loading...

Loading...