GROVE 11-19

CD3340B/YB4411 STRUCTURAL

11

Published 04/07/2015 Control # 569-00

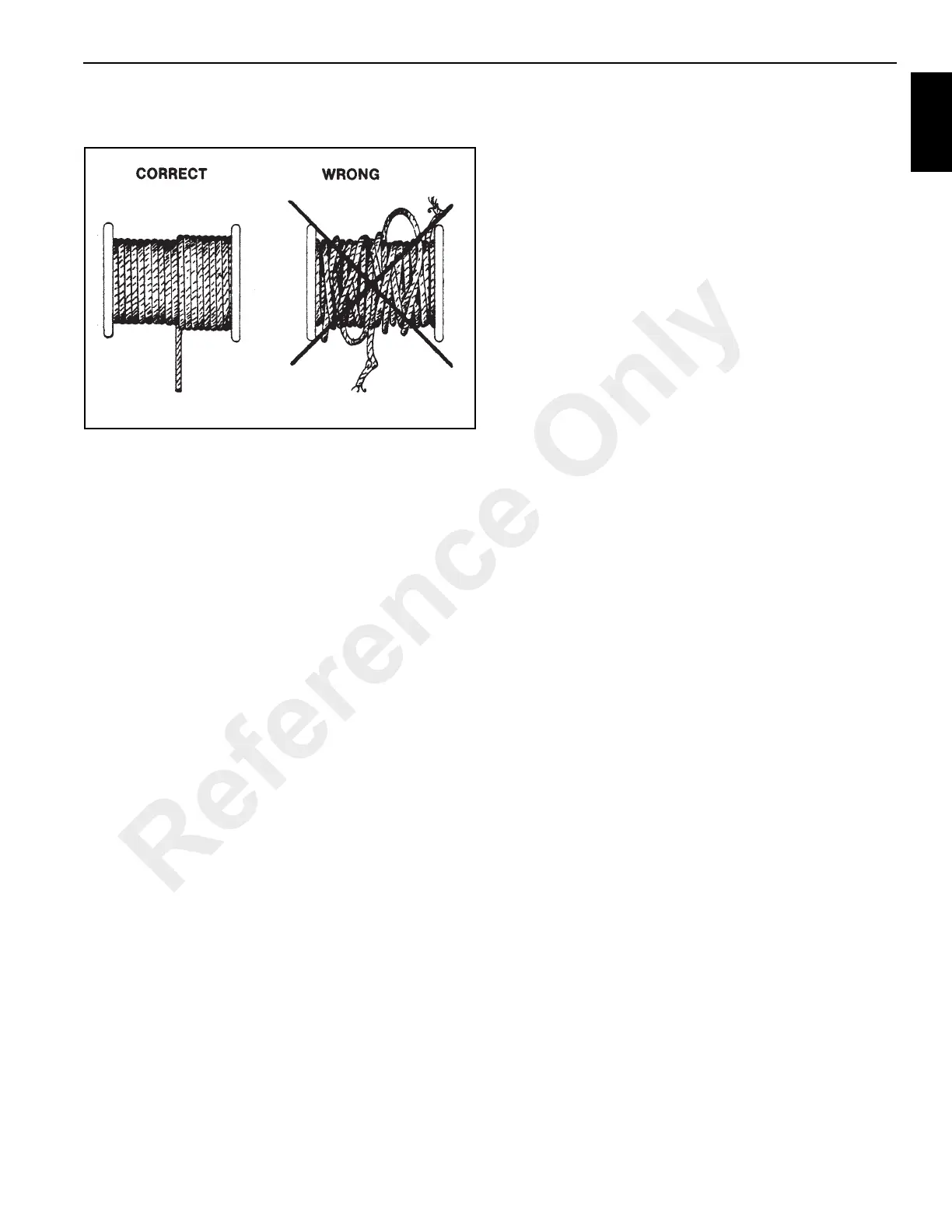

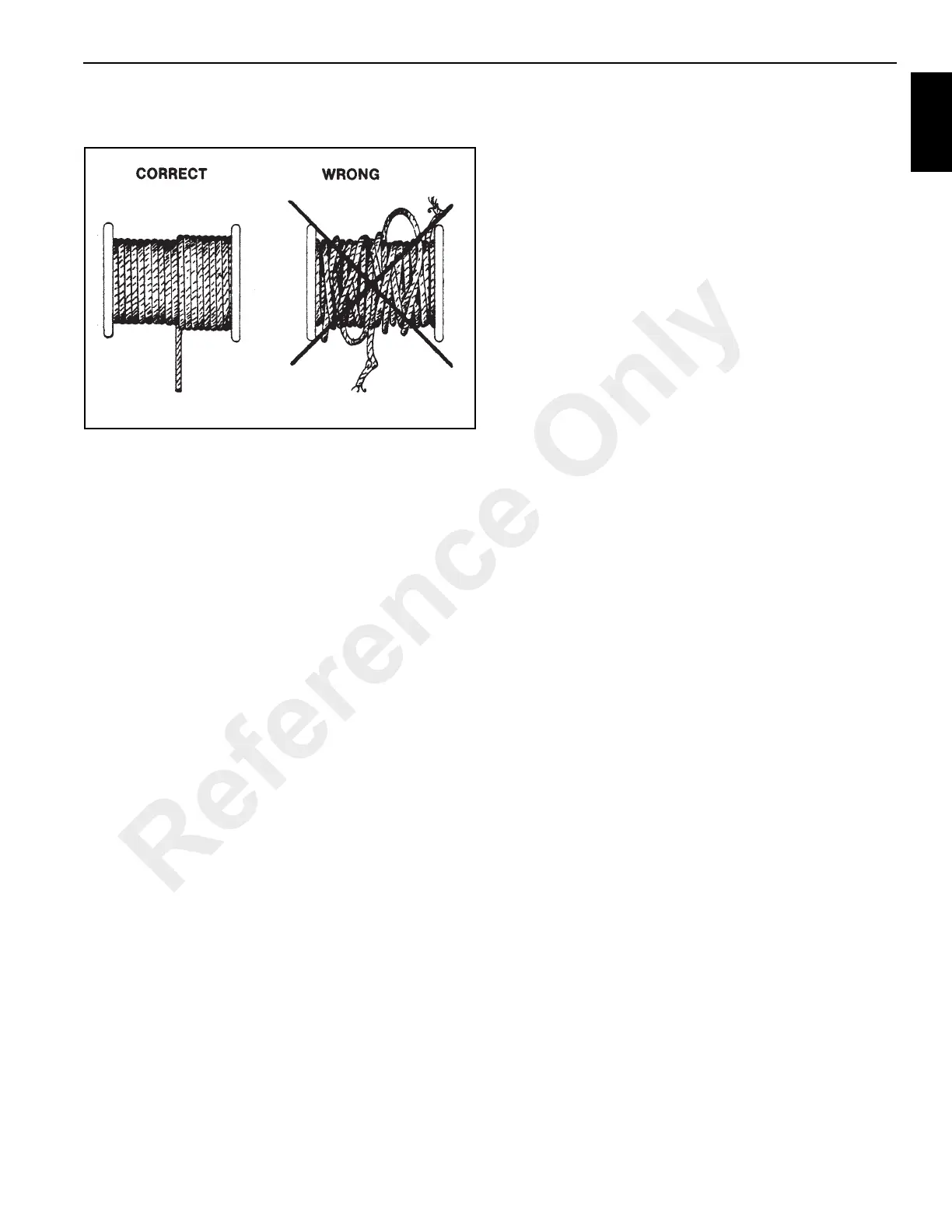

the drum. Loose windings will increase wear on the wire

rope and cause bad performance.

4. After installation, operate the hoist with a minimum load

until you see the wire rope is moving easily over the

sheaves and is winding correctly on the hoist drum.

5. Gradually increase the speed and load until the wire

rope is moving at normal load and speed. This run-in

period adjusts the moving parts to each other.

MAIN HOIST

Theory of Operation

The main hoist design is composed of high speed, low

torque gerotor motor, driving through a multiple disc brake,

and a pair of planet gear sets to the cable drum.

The multiple disc brake is spring applied and hydraulically

released through a port in the brake housing. During inhaul

(Figure 11-31) the brake is not released, since the load is

driven through a one-way cam clutch, bypassing the brake.

When the load comes to a stop, the cam clutch locks up and

the load is prevented from moving by the brake.

During payout (Figure 11-32), a brake valve is used to

prevent the load from moving faster than desired. This brake

valve partially blocks the main line from the motor back to the

control valve, allowing only a limited amount of oil through

the motor. The brake valve modulates by sensing pressure

on the other main line from the main control valve to the

motor. Also, any time there is sufficient pressure to modulate

the brake valve, this same pressure releases the multiple

disc brake.

Reference Only

Loading...

Loading...