GROVE 1-7

CD3340B/YB4411 INTRODUCTION

Published 04/07/2015 Control # 569-00

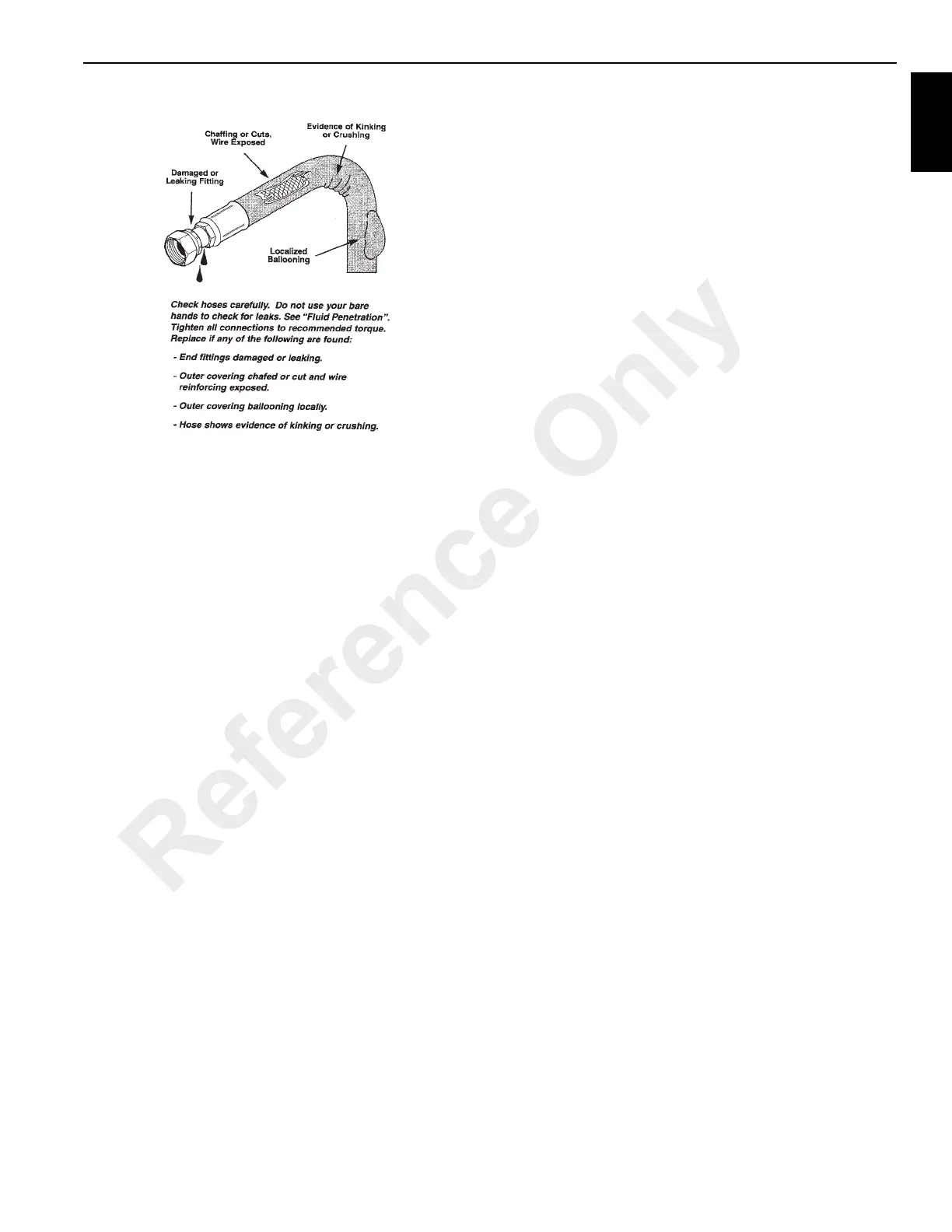

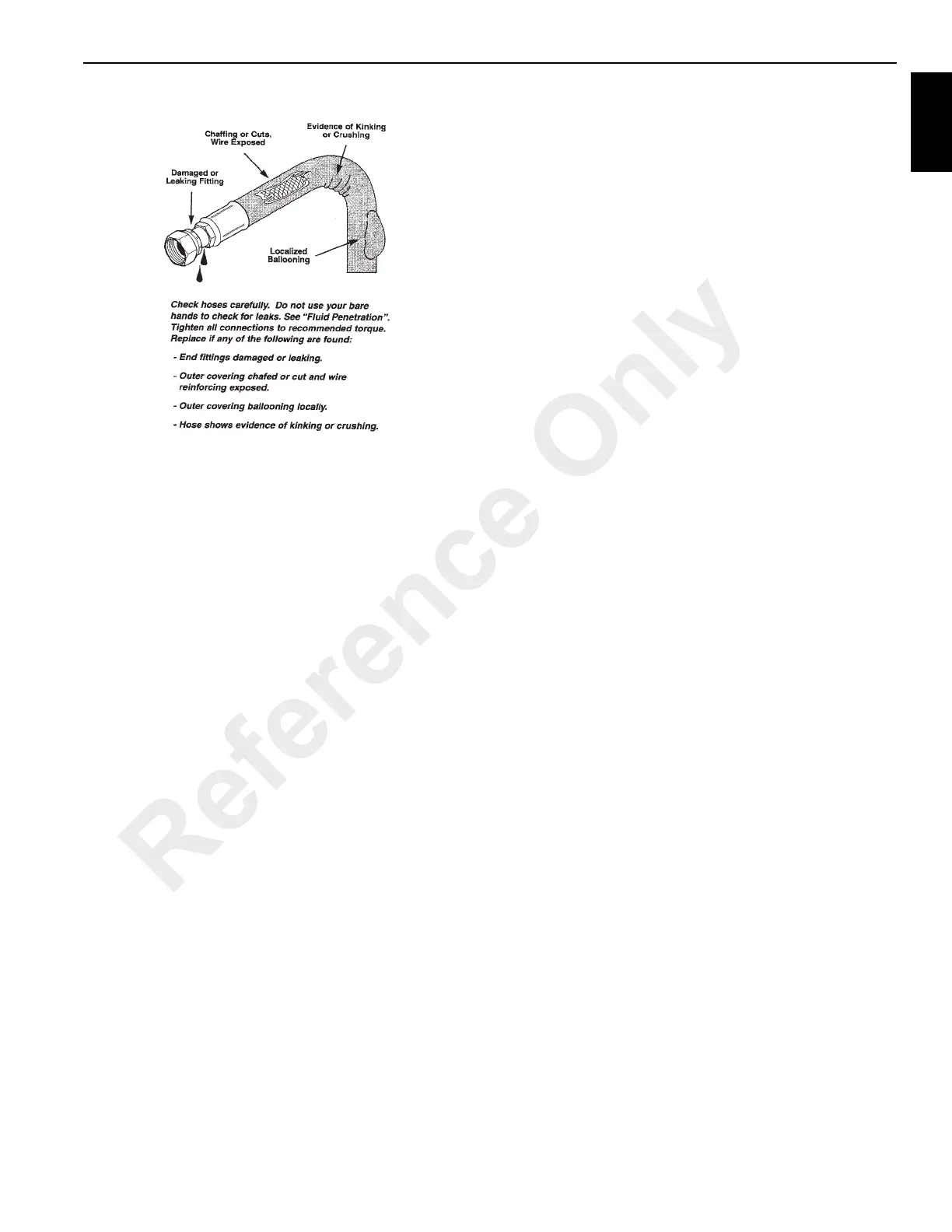

Installation

1. When installing a new hose, loosely connect each end

and make sure the hose takes up the designed position

before tightening the connection. Clamps should be

tightened sufficiently to hold the hose without crushing

and to inhibit chafing.

2. If a hose is replaced on a moving part, be sure it does

not foul by moving the part through its complete range of

movement.

3. Be sure any hose which has been installed is not kinked

or twisted.

4. Free moving, unsupported hoses must never touch each

other or related work surfaces. This causes chafing and

reduces hose life.

BEARINGS

Removal

1. Bearings should never be removed unless absolutely

necessary. Always use the recommended puller to

reduce the risk of bearing or related component

damage.

2. When bearings or bushings are removed, check that the

bearing is free from discoloration, nicks, scuffing, and

signs of overheating. If in doubt, replace the bearing or

bushing.

Cleaning

Bearings acceptable for service should be cleaned in a

suitable solvent and immersed in clean lubricating oil until

needed.

Installation

1. Be sure bearings are installed with care during servicing,

maintenance and repair.

2. Whenever possible, always install the bearing on the

rotating part first.

3. Use proper tools or a press when installing a bearing or

bushing.

4. In the absence of the proper tools or press, when

installing press fit bearings and bushings, heat the

bearing and/or the casing in hot oil to assist in the

installation.

HYDRAULIC PRESSURE TESTING

Prior to pressure testing, be sure all hoses are in good

condition and all fittings are tight.

Use a pressure gauge with a range that is high enough to

measure the specific pressure.

Comply with the correct procedure to inhibit damage to the

system or the equipment to eliminate the possibility of injury.

FATIGUE OF WELDED STRUCTURES

Experience has shown that highly stressed welded

structures when repeatedly subjected to varying stresses

caused by twisting, shock, bending, and intentional and/or

unintentional overloads, often become subject to weld

cracking which may be attributed to fatigue of the welded

joint. This condition is not uncommon in construction

equipment.

Equipment should be periodically inspected for evidence of

weld fatigue. The frequency of these inspections should

increase with the age of the equipment and the severity of

the application.The following are known high stress areas

applicable to Grove machines, and a visual inspection of

these areas should be made part of an owner’s planned

preventive maintenance program:

• Telescopic Boom: wear pad retaining structures,

hydraulic cylinder attaching points, boom pivot shaft

retaining structures.

• Outrigger pads, beams, boxes and attachment

structures.

• Main frame: generally in the area of doubler plates and

cross members; at the junction of front and rear frame

members on truck cranes.

• Turntable bearing connection—where bearing is welded

to the crane superstructure or chassis.

• Counterweight support structures.

• Chassis axle and suspension mounting structures.

• Hydraulic cylinder end connections.

Reference Only

Loading...

Loading...