STRUCTURAL CD3340B/YB4411

11-56

Published 04/07/2015 Control # 569-00

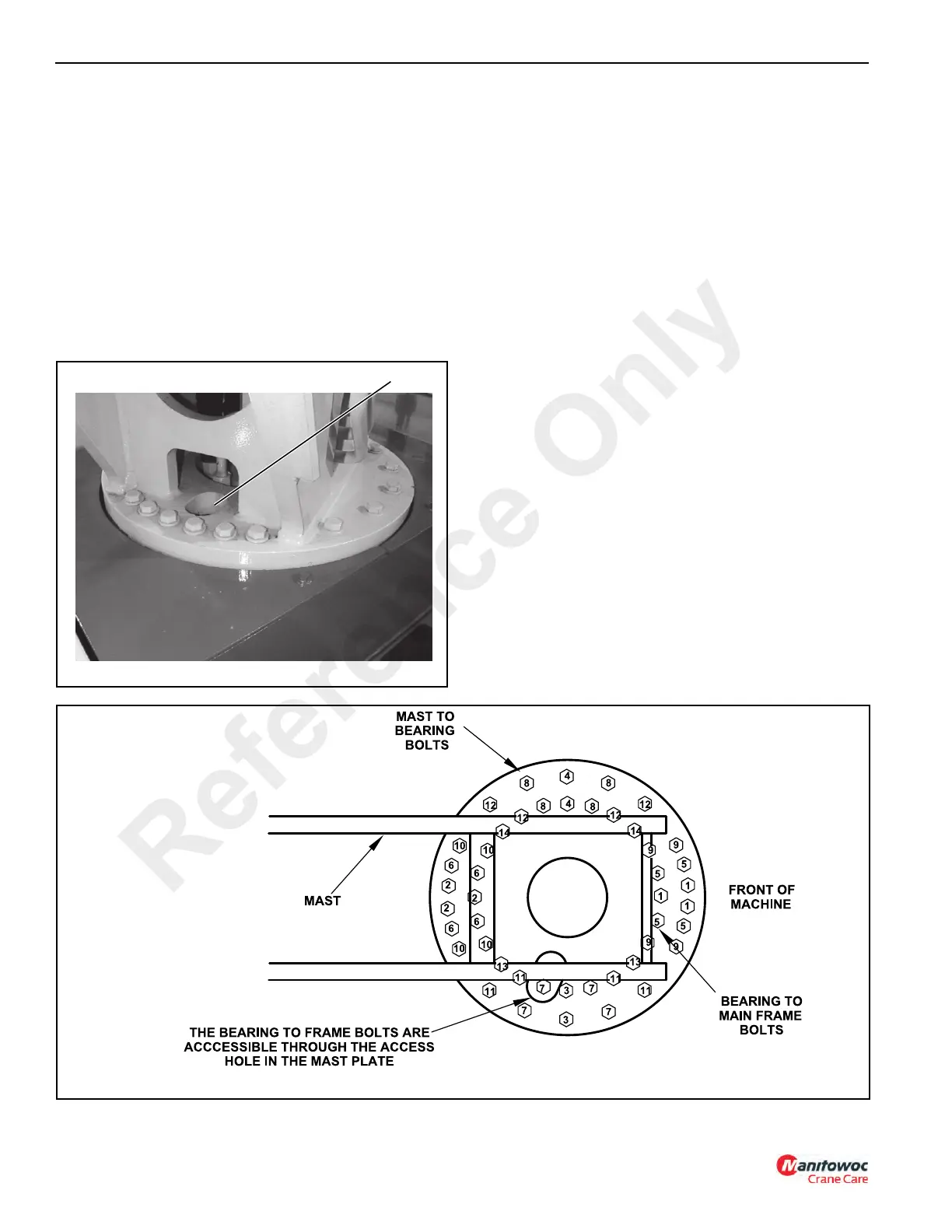

Mast Bearing

The mast bearing is a ball thrust bearing. The inner race

rotates inside the outer race on a row of steel balls.

Apply grease after every 50 hours of operation. Use a

Lithium based, E.P. No. 2 bearing grease or equivalent.

There are two grease fittings to grease the bearing and they

are directly across from each other. Rotate the mast until the

access hole (Figure 11-139) aligns with the grease fitting.

Apply grease to the bearing. Rotate the mast through several

rotations and then repeat the procedure with the other

grease fitting. The old grease will be removed at the bottom

of the bearing.

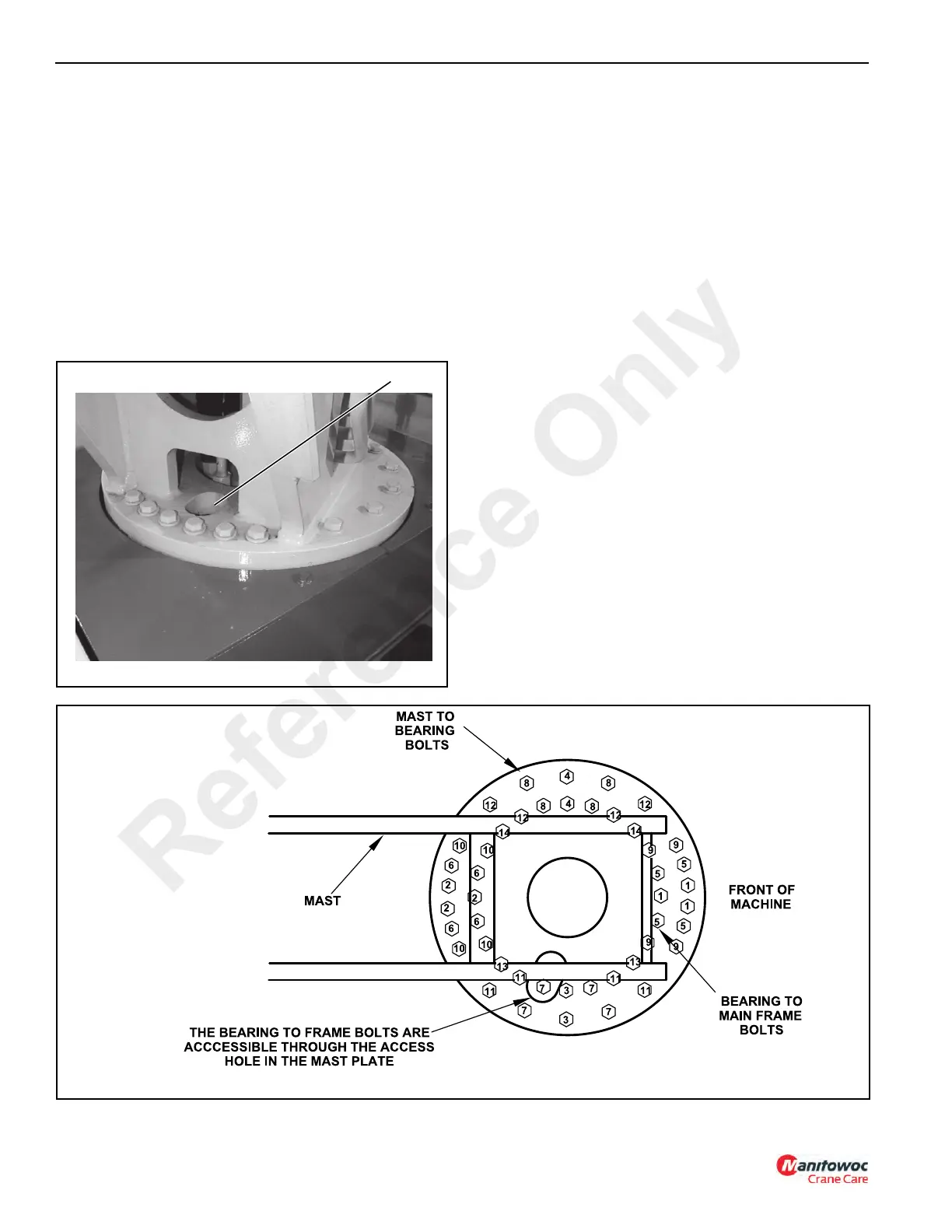

Mast Bearing Bolts

Very high stress is put on the mast bolts during crane

operation. It is important that these bolts be checked at

regular intervals.

Check the torque on the bolts after the first 50 hours of

operation, and then after every 250 hours of operation. Make

a record of any loose bolt. If any bolt does not hold to correct

torque after the second check, remove and replace the bolt.

A loose bolt indicates possible failure of the bolt.

The correct torque on each outside bolt (mast to swing

bearing) should be 245 Nm (180 lb-ft). The correct torque on

each inside bolt (swing bearing to frame) should be 384 Nm

(282 lb-ft).

Use the torque sequence shown in Figure 11-140 when

checking the torque on the bolts.

NOTE: Use only special hardened bolts for replacement of

the mast bolts. Order the bolts from your distributor,

see your parts manual.

NOTE: If a broken bolt is found, replace the bolt and also

replace the bolt on each side of the broken bolt.

FIGURE 11-139

P0325

Access Hole

Reference Only

Loading...

Loading...