GROVE 4-41

CD3340B/YB4411 HYDRAULIC SYSTEM

Published 04/07/2015 Control # 569-00

Installation

1. Place a new gasket on the face of the swing motor

mounting flange.

2. Align the splines of the swing motor shaft with the

splines of the worm gear shaft of the swing gear box.

Install the swing motor to the gearbox with two socket

head capscrews and lockwashers.

3. Connect the hydraulic lines and fittings to the swing

motor.

4. Start the engine and slowly rotate the mast to remove

any air in the swing hydraulic circuit. Check for leaks.

Hoist Motor

Removal

1. Shut off the engine, set the parking brake.

2. Before disconnecting the hydraulic lines, clean the port

area of the hoist motor thoroughly. Disconnect the

hydraulic lines from the hoist motor. Put caps and plugs

on the hoses and ports to keep dirt out.

3. Loosen and remove the two capscrews and

lockwashers securing the motor to the hoist. Remove

the hoist motor and gasket. Discard the gasket.

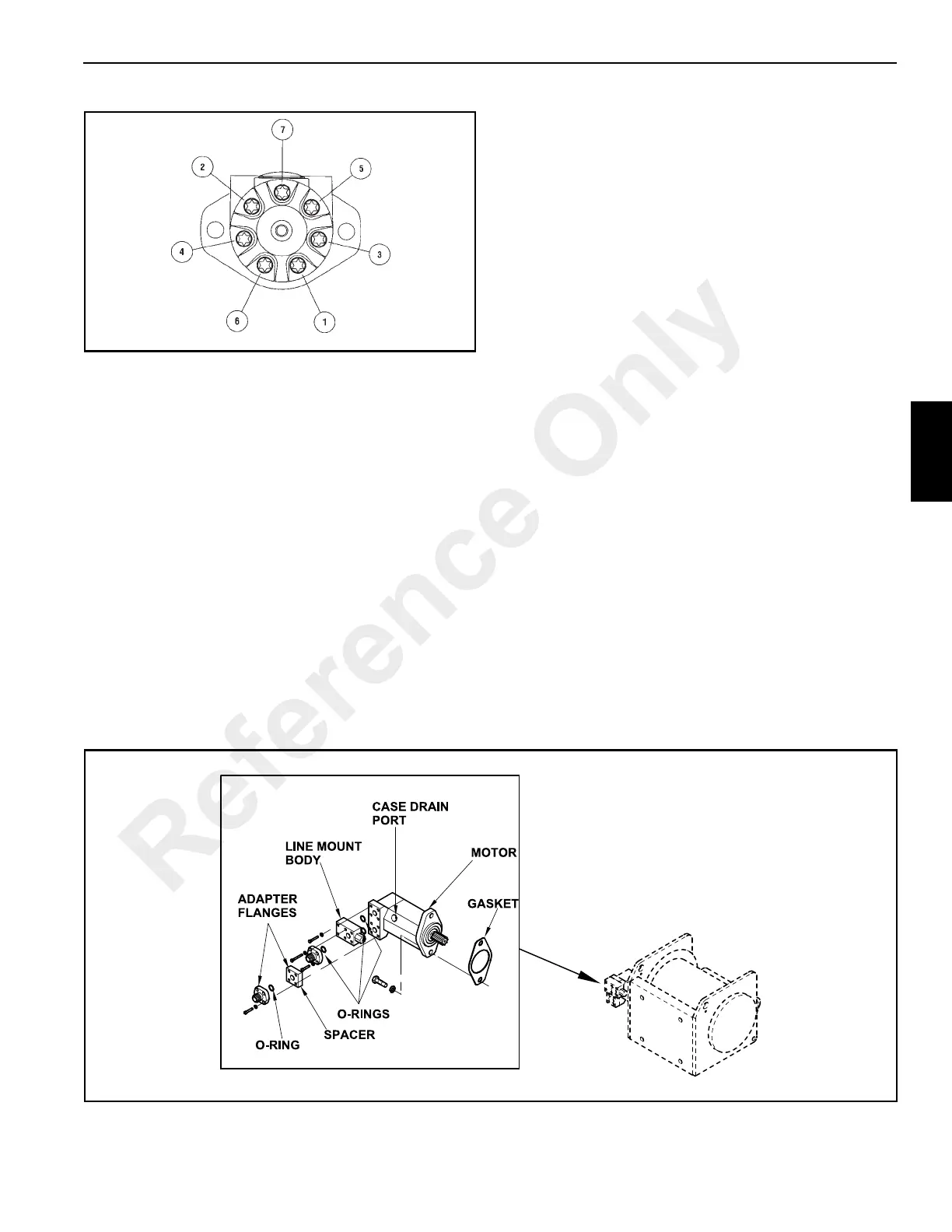

4. Remove the adapter flanges, spacer block and line

mount body (Figure 4-35) from the pump. Discard all O-

rings.

Disassembly

The hoist motor is not field serviceable. It must either be

replaced or returned to your distributor for repair.

Installation

1. Install the line mount body (Figure 4-35), spacer and

adapter flanges to the hoist motor. Be sure to use new

O-ring seals.

2. Install the hoist motor and new gasket to the hoist using

two capscrews and lockwashers.

NOTE: To inhibit cavitation and damage to the motor due

to lack of lubricating hydraulic oil, DO NOT start the

motor without first being filled with hydraulic oil.

3. Fill the hoist motor through the case drain hole

(Figure 4-35) to the bottom of the fill plug with clean

hydraulic oil.

4. Connect all the hydraulic hoses and fittings to the motor.

5. Start the engine and slowly run the boom hoist through

several cycles to remove any air in the system. Check

for hydraulic leaks.

Reference Only

Loading...

Loading...