GROVE 11-57

CD3340B/YB4411 STRUCTURAL

11

Published 04/07/2015 Control # 569-00

Inspection for Bearing Wear

Because of conservative design parameters, static loading

and slow intermittent rotation, there are very few mast

bearings that ever see their full design use.

However, the mast does have moving internal parts that are

prone to wear if not properly maintained. As the bearing

wears, there will be free-play or movement in the bearing.

Some of the symptoms of mast bearing wear are:

• Metal particles in the grease around the seal.

• Increased drive power required.

• Noisy rotation.

• Rough rotation.

If one or more of the above symptoms are evident, the

following procedure should be used to check the bearing for

excessive wear:

1. On a level, hard packed surface, set the crane up level

on its outriggers.

2. Place the boom in forward horizontal position. Fully

extend the booms.

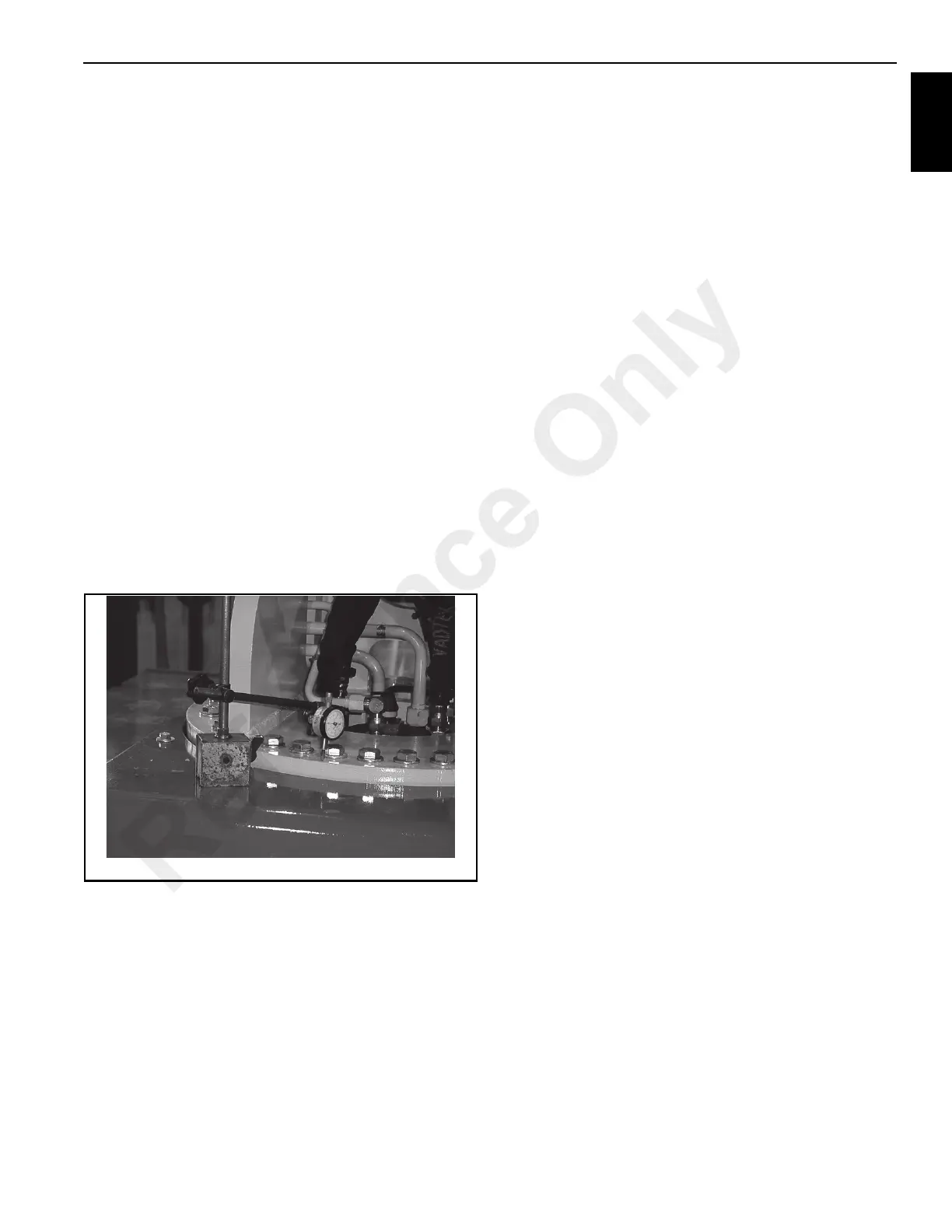

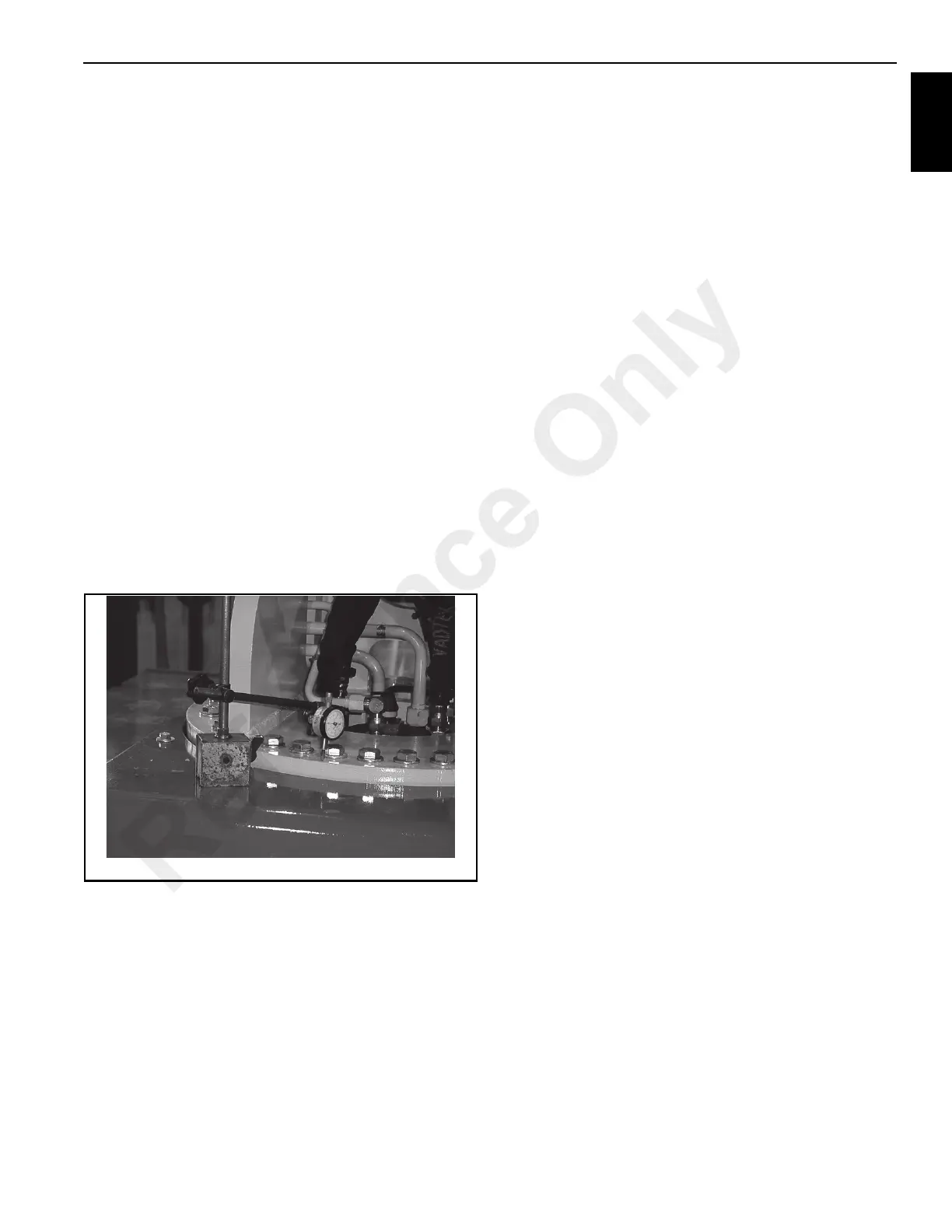

3. Place a dial indicator on the swing gearbox cover and

mast as shown in Figure 11-141.

4. Set the dial indicator to zero.

5. Raise the boom to its full upright position and record the

amount of movement on the dial indicator.

6. Rotate the boom 180° and repeat steps 2 thru 5.

7. Average the two readings. The maximum allowable

movement is 0.91 mm (0.035 in). The mast bearing must

be replaced if the movement is greater than the

maximum allowable movement.

Replacing the Mast Bearing

Removal

1. See boom removal and remove the boom from the mast.

2. Disconnect the lift cylinder hoses. Plug/cap the hoses

and cylinder ports. Remove the lift cylinder.

3. Put tags on the upper swivel hydraulic hoses and lines

with the swivel port to which the hydraulic hose or line

connects.

4. Disconnect the hydraulic hoses and lines from the upper

swivel ports. Put caps or plugs on the fittings and

hydraulic lines and hoses.

5. Remove swivel stop (39, Figure 11-142) from the bottom

of hydraulic swivel (38) and support the swivel in place.

Remove bolts (53) and washers (1).

6. Connect a hoist capable of handling the weight of the

mast. Remove the 22 capscrews (18) and structural

washers (19) that fasten mast (9) to mast bearing (30).

7. Remove the mast (9) and place on blocks.

8. Remove the 24 capscrews (31) and structural washers

(6) and remove the mast bearing (30).

Reference Only

Loading...

Loading...