GROVE 9-3

CD3340B/YB4411 BRAKE SYSTEM

Published 04/07/2015 Control # 569-00

charging. This does not noticeably affect the operation of

these components. Full system pressure is available to the

downstream components at all times, providing oil delivery

and pressure from the pump and relief valve are not

impeded.

The accumulator charging flow rates and upper and lower

pressure limits are set at the time of manufacture and are not

adjustable.

Low Pressure Warning Switch

The low pressure warning switch illuminates a red light on

the dash when the brake pressure goes below 5861 kPa

(850 psi). When the red light illuminates, there still is enough

pressure for brake application to stop the crane. After which,

the brake system must be checked and repaired.

Accumulator

The accumulator is a hydro-pneumatic, piston-type

accumulator. This means that the accumulator is charged

with nitrogen and stores hydraulic fluid to a pressure of

13790kPa (2000 psi) for brake system usage.

Needle Valve

The needle valve is used during service of the brake system.

When closed, It shuts off the hydraulic supply from the

accumulator, holding a pressure in the accumulator. This

eliminates the need to charge the accumulator after brake

system service.

NOTE: The needle valve must in the open position for the

brake system to operate properly. If it is not open,

the charging pump will cycle every time the brake

pedal is depressed and if the crane’s engine stops

there may not be enough pressure to stop the

crane.

Brake Modulating Valve

The brake modulating valve is a closed-center spool design.

When the valve is in no-applied position, brake port (A,

Figure 9-1) is open to tank port (T). As the valve is initially

actuated, tank port (T) is closed off from brake port (A).

Additional actuation opens pressure port (P) to brake port

(A). More input force will increase the pressure to brake port

(A) until actuation effort and hydraulic reaction forces are

balanced. When actuation is released, the valve returns to its

non-applied position.

Brake Light Switch

The brake light switch illuminates the brake lights when the

brake modulating valve builds system pressure to 552 kPa

(80 psi).

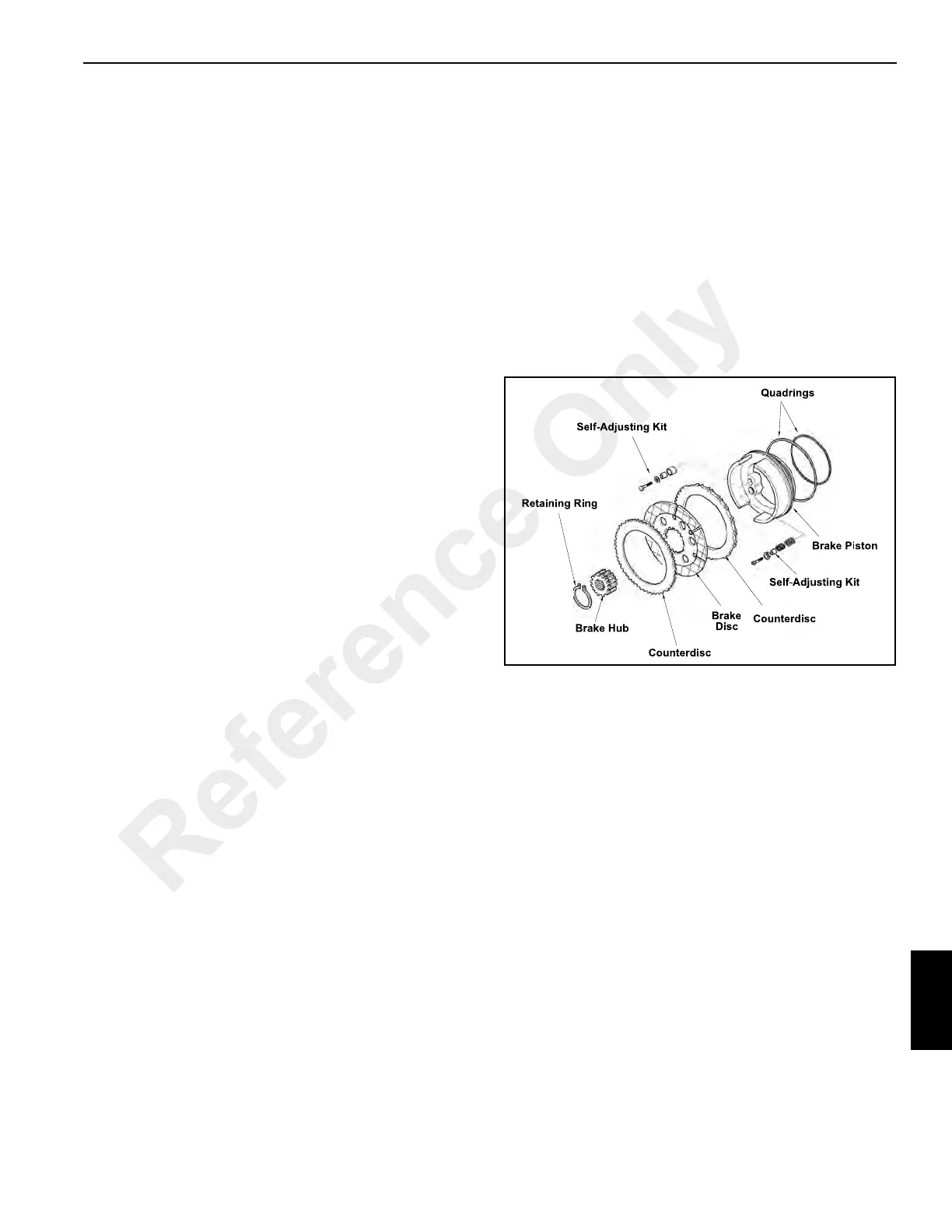

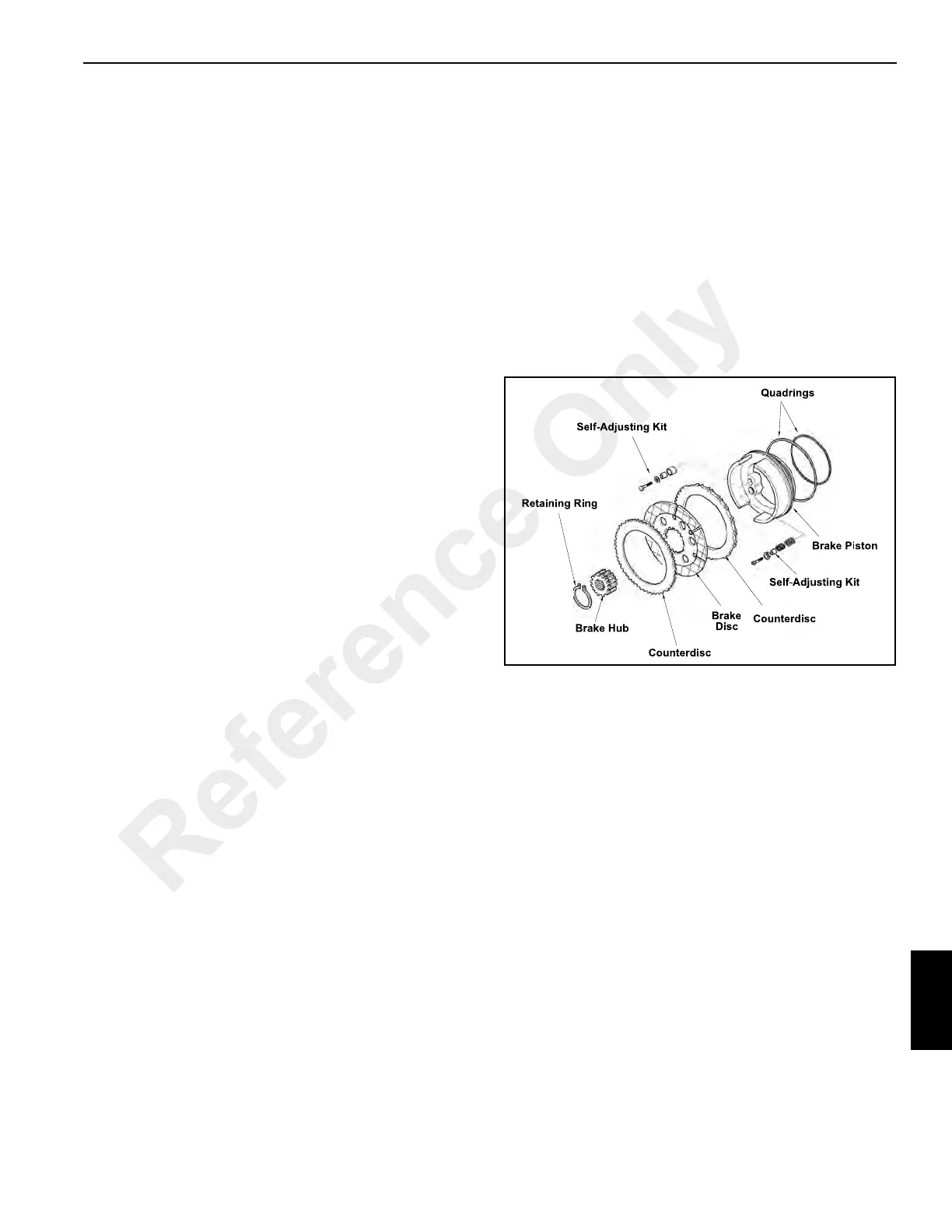

Front Axle Brakes

The front axle brakes are self-adjusting oil immersed and are

located on both sides of axle center housing (Figure 9-2).

Each brake assembly consists of one brake disc and two

counterdiscs. The brakes are applied when the brake

modulating valve is actuated. Hydraulic fluid under pressure

reacts against the brake pistons, forcing the brake

counterdiscs against the brake disc, slowing and/or stopping

the crane.

Parking Brake System

Description of Operation

The parking brake system consists of two-way switch in the

instrument panel, a solenoid valve and a parking brake. The

system connects into the service brake system (Figure 9-1)

and uses the accumulator for system pressure.

Parking Brake

The parking brake is a disc-type brake (Figure 9-3). The

brake disc is attached to the input shaft of the front axle. The

brake is attached to the frame behind the front axle. When

the parking brake switch is placed in the engage position,

hydraulic supply is shut off to the parking brake and the

springs in the parking brake apply the brake pads against the

brake disc, holding the crane from moving.

Reference Only

Loading...

Loading...