HYDRAULIC SYSTEM CD3340B/YB4411

4-40

Published 04/07/2015 Control # 569-00

10. Before installing the flange and seal assembly over shaft

(9, Figure 4-24), place a protective sleeve or bullet over

the shaft. Then lubricate the space between exclusion

seal (2) and pressure seal (5), as well as the lips of both

seals (see Figure 4-32).

Install flange. Rotate flange slowly while pushing down

over the shaft. Be careful not to invert or damage the

seals.

11. After removing the protective sleeve or bullet, clamp the

motor in a vise. Make sure the shaft cannot fall out.

Install dry screws and alternately torque them

immediately to 28 Nm (250 lb-in). If you use primer,

allow to cure for 10 to 15 minutes. Without primer, allow

6 hours curing before subjecting the motor to high torque

reversals.

Gerotor End

12. Reposition the motor in the vise with gerotor end up.

Clamp across the ports. Do not clamp on side of

housing.

NOTE: To aid installation of seals, apply a light coat of

clean petroleum jelly to seals. Do not stretch the

seals before installing them in a groove.

13. Pour approximately 1 ounce (35 mm) of clean hydraulic

oil in the output shaft cavity.

14. Install O-ring (13, Figure 4-24) in the housing groove.

Avoid twisting the seal.

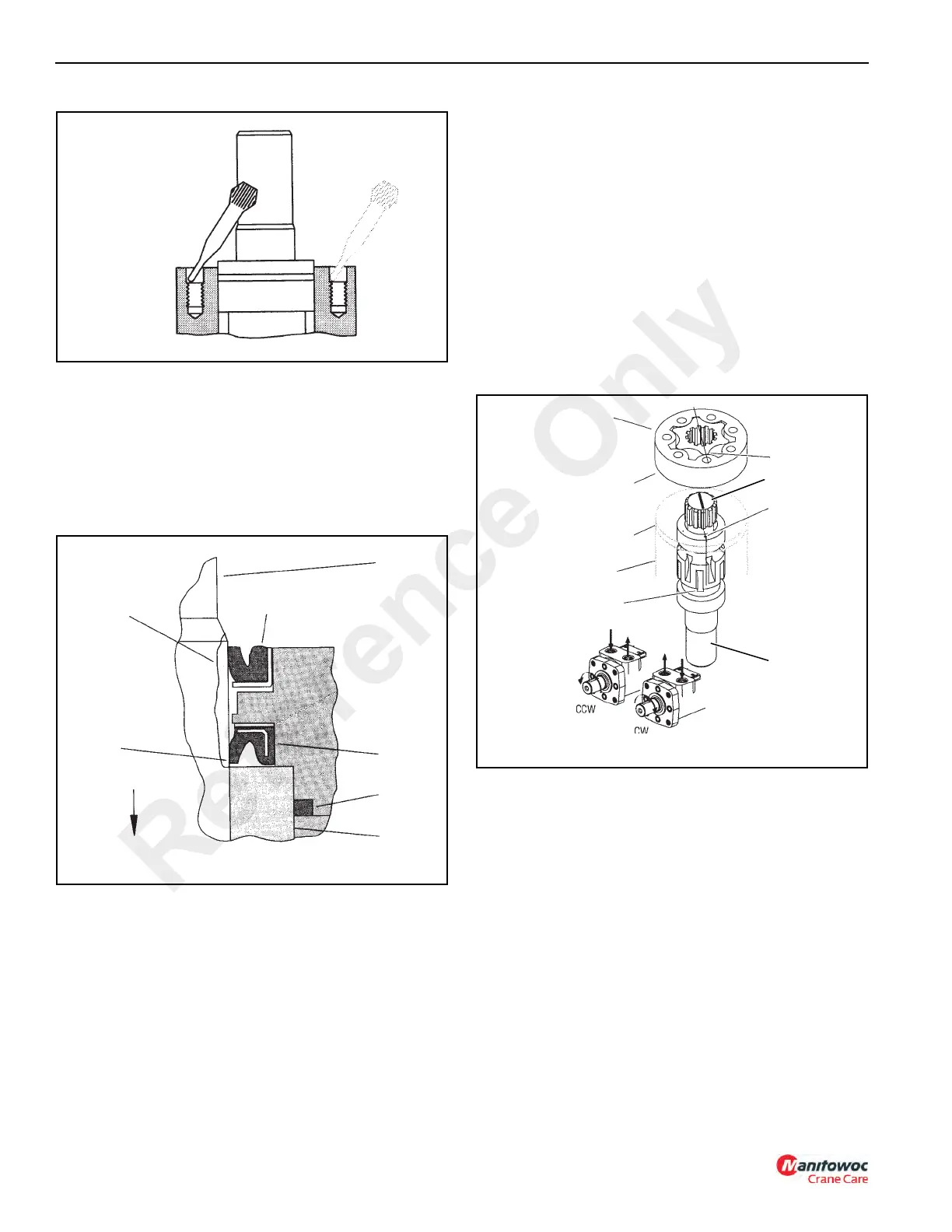

Timing Procedure

15. Install drive shaft (14, Figure 4-24). Use a felt tip pen to

mark one drive tooth. Align this mark with the timing dot

on the output shaft (Figure 4-33).

NOTE: If drive shaft (14) is not symmetrical, install larger

splined end into output shaft (9).

16. Install spacer plate (15).

17. Install seal (13) in gerotor seal groove. Carefully place

gerotor on spacer plate, seal side toward the spacer

plate. Align any star point with tooth marked on drive

shaft (Figure 4-33).

18. Rotate gerotor (16) to line up with bolt holes. Be careful

not to disengage star from drive or disturb the gerotor

seal.

19. Install seal (13) in end cap (17). Carefully place the end

cap on gerotor (16).

20. Install capscrews (19) and seal washers (18) in end cap

(17). Tighten the capscrews to 7.4 Nm (40 lb-in). Make

sure the seal washers are properly seated. Then, tighten

the capscrews to a torque of 27-29 Nm (235-250 lb-in) in

the sequence shown in Figure 4-34.

a0770

FIGURE 4-31

Place Tip of

Applicator at Top of

Threaded Portion

Apply 3 or 4

Drops In Each

Hole

a0771

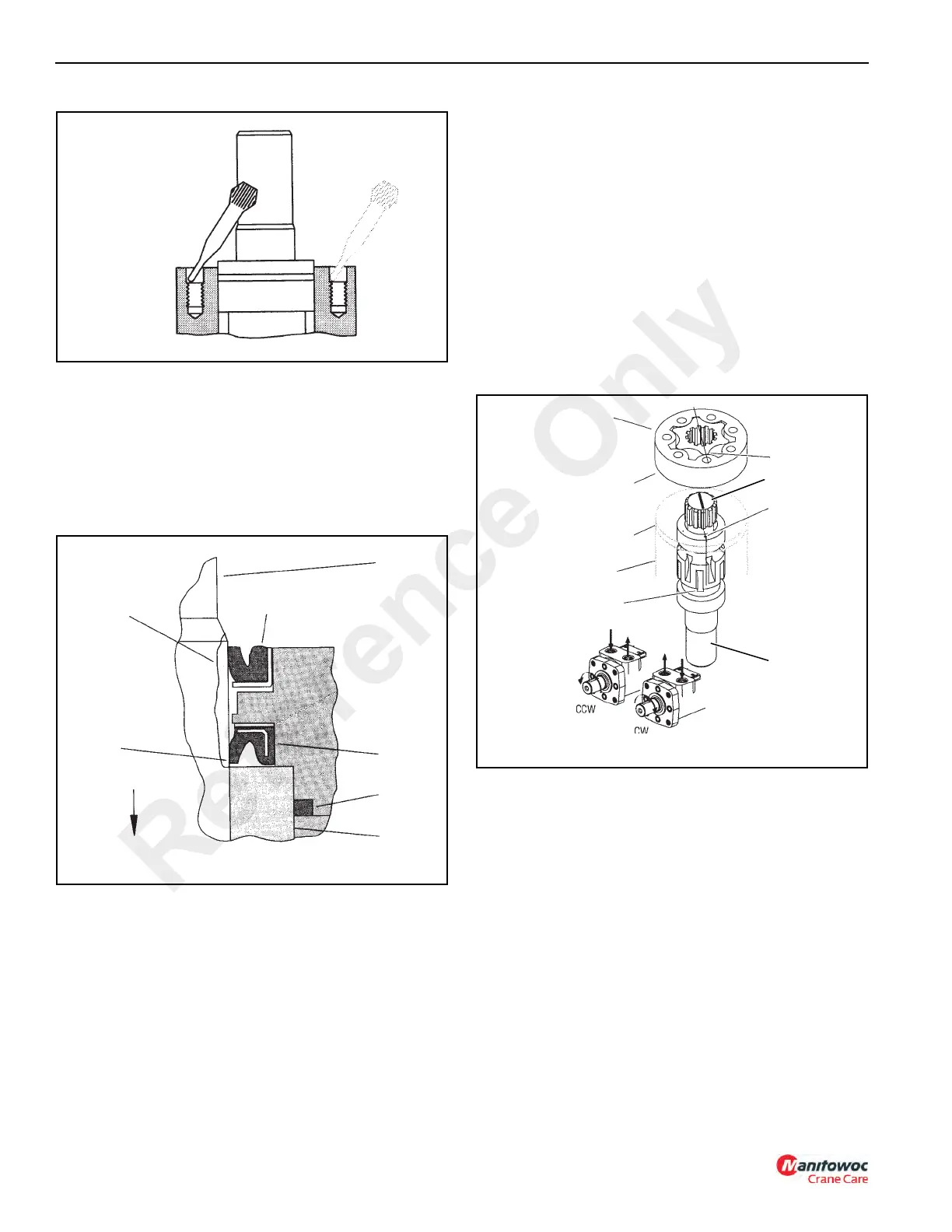

FIGURE 4-32

Interior of

Motor

This Lip to

Face

Inward

Apply Petroleum

Jelly Across This

Area. See Step

10.

Extrusion Seal

(Lip Face Outward)

Output

Shaft

Pressure

Seal

Seal

Bearing

Race

a0772

FIGURE 4-33

Gerotor

Gerotor Seal

(This Side)

Spacer Plate

Housing

Forward

Valving Slot

Timing Dot

Star Point

Drive Shaft

Output Shaft

Reference Only

Loading...

Loading...