Grove Published 3-1-2018, Control # 559-03 1-13

RT9130E-2 OPERATOR MANUAL INTRODUCTION

Periodic Inspection

Wire rope should be inspected periodically/annually or at a

shorter time interval if necessitated by environmental or

other adverse conditions, and shall cover the entire length of

the wire rope. Only the outer surface of the wire rope need

be inspected, and no attempt should be made to open the

rope. Periodic inspection should include all items listed

under frequent inspection plus the following:

• Inspect for reduction of rope diameter below nominal

diameter.

• Inspect for severely corroded or broken wires at end

connections.

• Inspect for severely corroded, cracked, bent, worn, or

improperly applied end connections.

• Inspect wire rope in areas subjected to rapid

deterioration such as:

• Sections in contact with saddles, equalizer sheaves,

or other sheaves where wire rope travel is limited.

• Sections of wire rope at or near terminal ends where

corroded or broken wires may protrude.

• Inspect boom nose sheaves, hook block sheaves, jib/jib

sheaves, auxiliary boom nose sheaves, and hoist drums

for wear. Damaged sheaves or hoist drums can

accelerate wear and cause rapid deterioration of the

wire rope.

Wire Rope Inspection/Replacement (All Wire

Rope)

No precise rules can be given for determination of the exact

time for replacement of wire rope since many variable factors

are involved. Determination regarding continued use or

replacement of wire rope depends largely upon the good

judgement of an appointed and qualified person who

evaluates the remaining strength in a used rope after

allowance for any deterioration disclosed by inspection.

Wire rope replacement should be determined by the

following information excerpted from a National Consensus

Standard as referenced by Federal Government Agencies

and as recommended by Manitowoc. All wire rope will

eventually deteriorate to a point where it is no longer usable.

Wire rope shall be taken out of service when any of the

following conditions exist:

• Kinking, crushing, birdcaging, or any other damage

resulting in distortion of the rope structure.

• Evidence of any heat damage from any cause.

• Reductions from nominal diameter of more than 5%.

• In running ropes, six randomly distributed broken wires

in one lay or three broken wires in one strand in one lay.

• In standing ropes, more than two broken wires in one lay

in sections beyond end connections or more than one

broken wire at an end connection.

• In rotation resistant rope, two randomly distributed

broken wires in six rope diameters or four randomly

distributed broken wires in 30 rope diameters.

• Severe corrosion as evidenced by pitting.

• Manitowoc recommends that for cable extended booms,

a single damaged wire rope assembly shall require

replacement of the entire set of extension cables.

• Manitowoc recommends for cable extended booms, that

jib cables be replaced every seven (7) years.

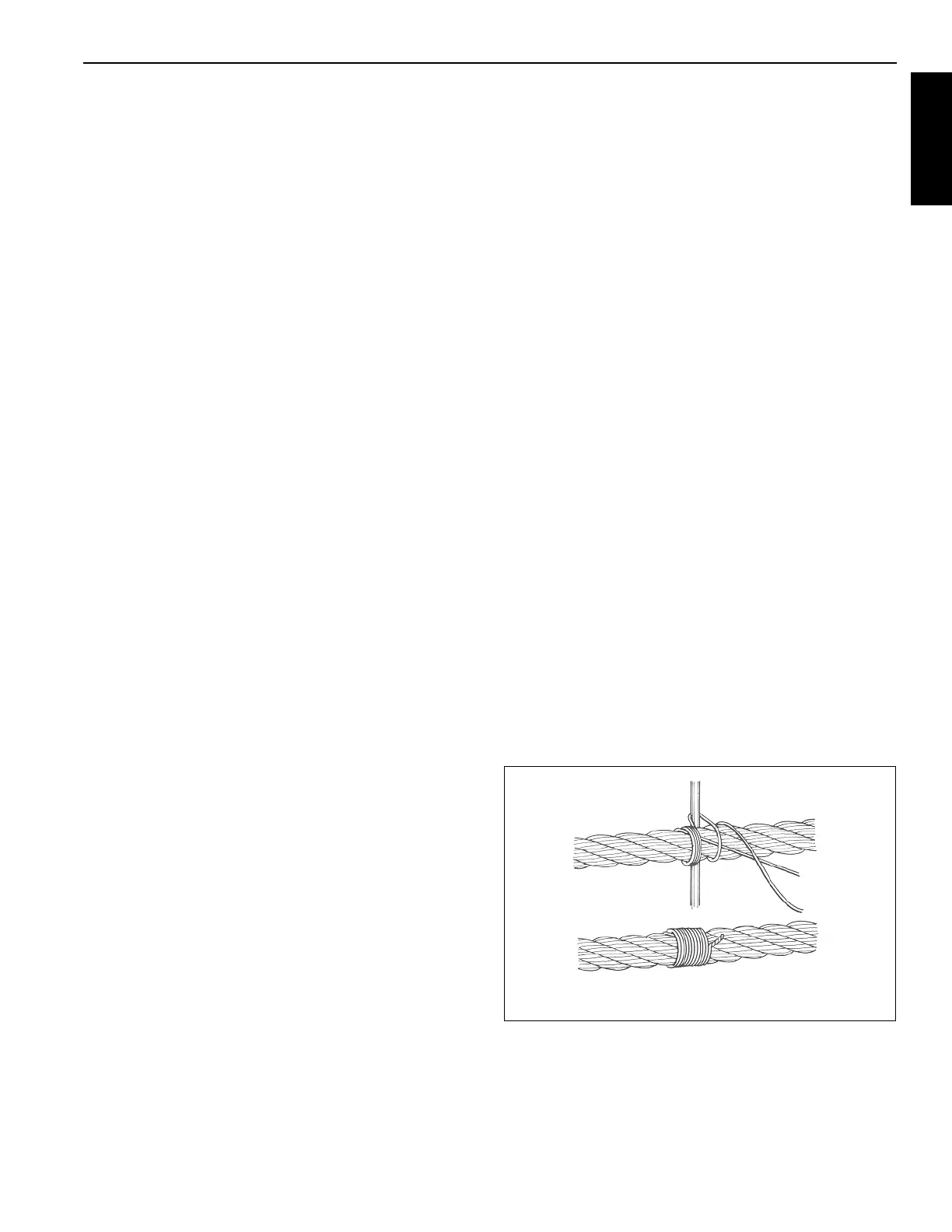

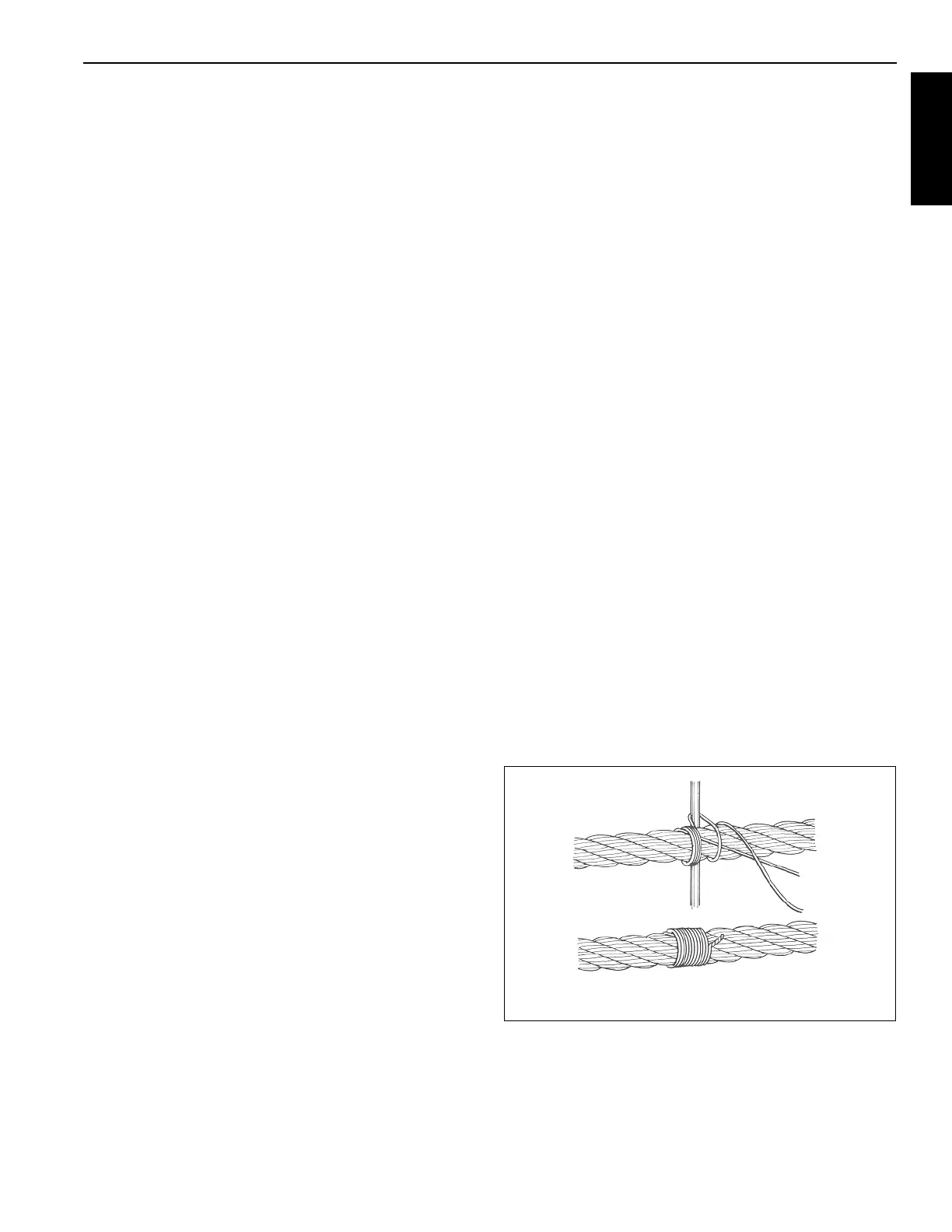

Seizing Wire Rope

It is important to seize the ends of rotation resistant wire

ropes to prevent the displacement and unraveling of the

individual wires and strands at the ends. All preformed and

non-preformed styles of wire rope should be seized prior to

cutting. Seizings must be placed on both sides of the point

where the wire rope is to be cut.

The two preferred methods for seizing wire ropes are:

Method 1

Using a length of soft annealed wire (Figure 1-6), place one

end in the groove between two strands of the wire rope. Turn

the long end of the annealed wire at right angles to the wire

and wrap it tightly over the portion in the groove.

The two ends of the annealed wire should be twisted

together tightly. Cut off the excess wire and pound the twist

flat against the wire rope.

Loading...

Loading...