POWER TRAIN TMS700E SERVICE MANUAL

7-46 Published 01-29-2015, Control # 512-01

clutch release yoke rides up and over the release

bearing (throw-out bearing) while the shaft goes into the

pilot bearing.

5. Install the 12 bolts and washers mounting the

transmission’s clutch housing to the engine flywheel

housing. Tighten the bolts; refer to Fasteners and

Torque Values on page 1-12 for the torque value.

6. Refer to Engine - Installation in this section and install

the engine and transmission.

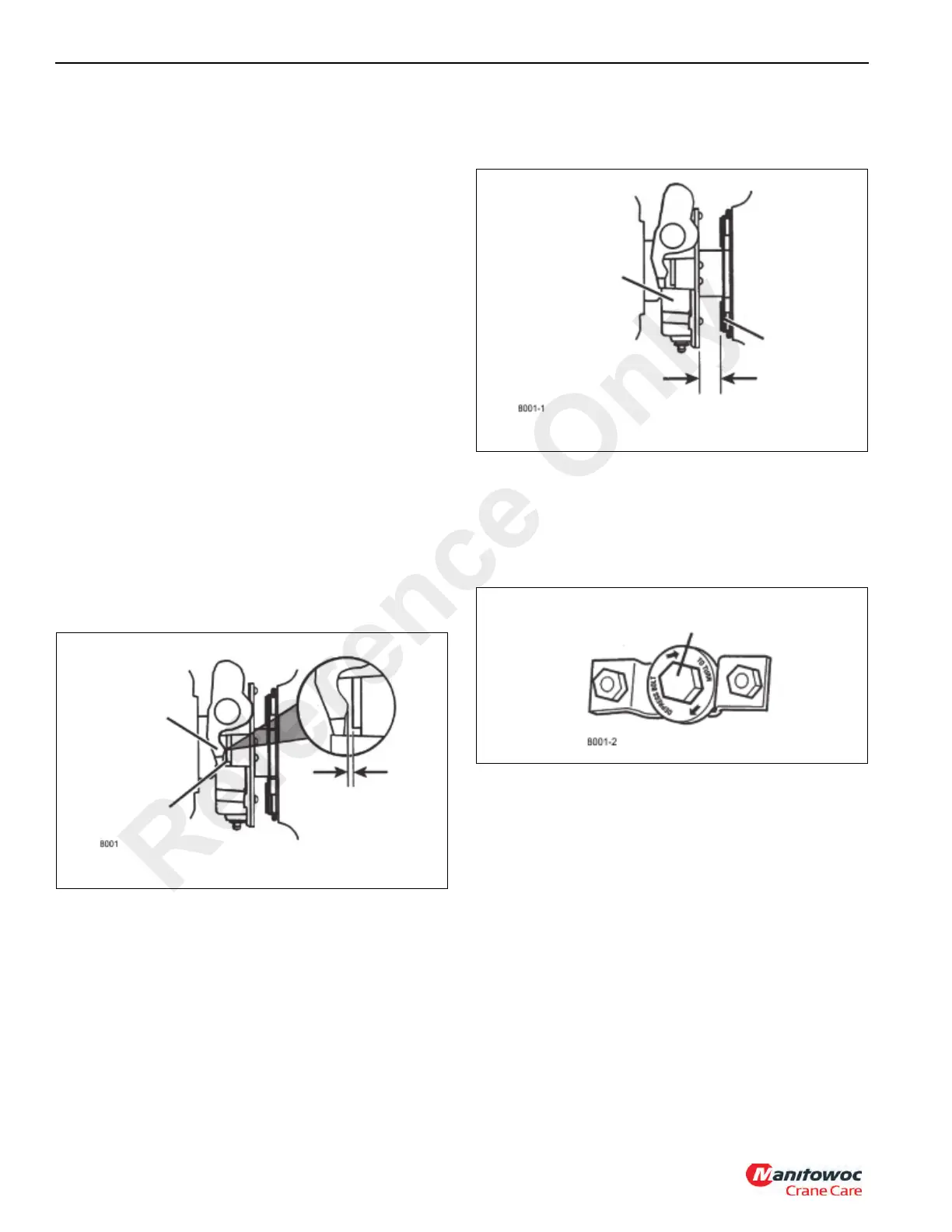

Clutch Adjustment Procedure

1. Remove the inspection plate from bottom of the clutch

housing.

2. Verify the following:

• Clutch lever is properly installed, the adjusting

screw on clutch pedal adjusting lever is equally

adjusted in either direction.

• The adjusting screw is set to 1.6-3.2 mm

(1/16-1/8 in) wear clearance, as shown,

(Figure 7-29).

• That all rod end bearings and jam nuts on control

rods are tight and have sufficient thread

engagement (4 threads min) on each rod.

• Cable is set to the middle of its adjustment range at

both ends.

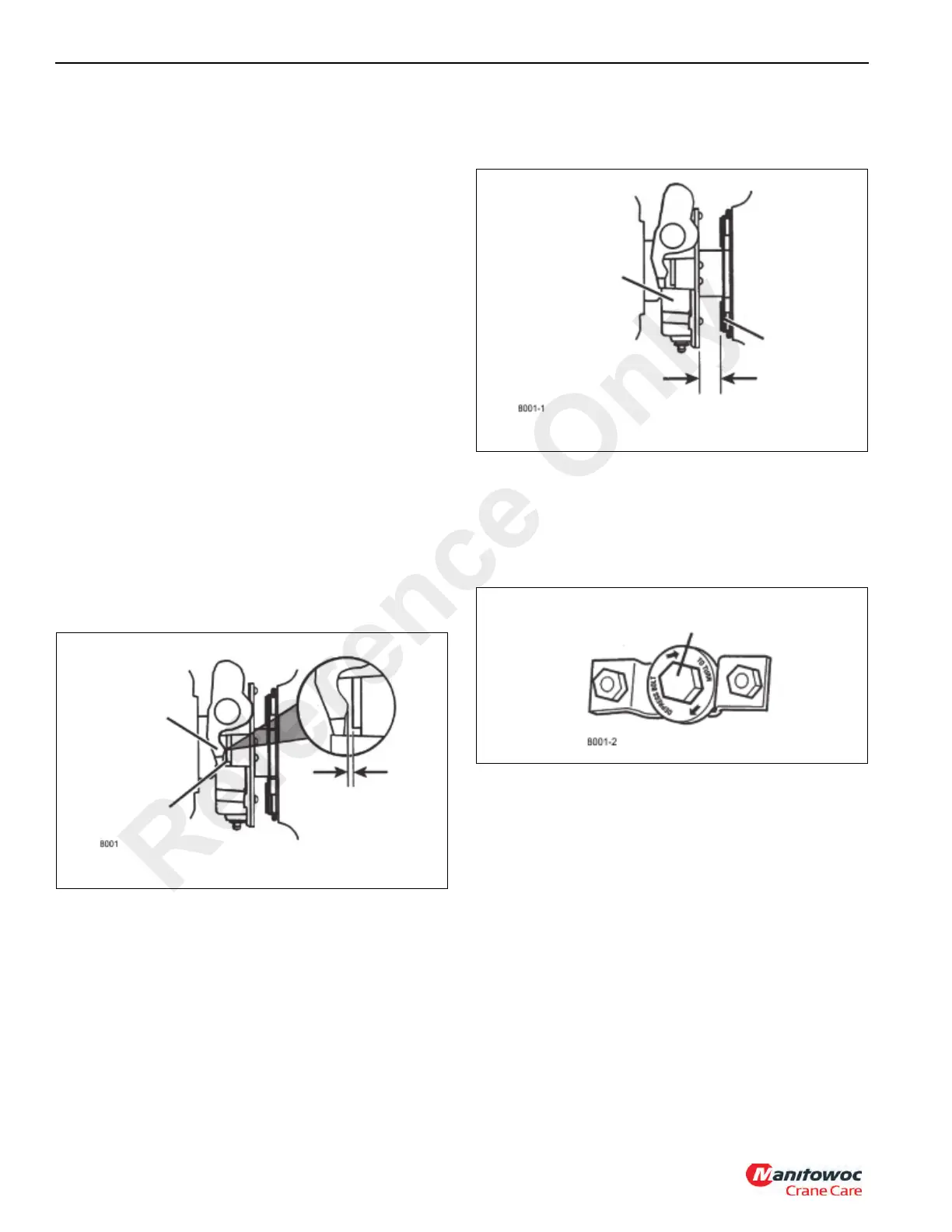

3. Visually check the travel of the release bearing after

working the pedal several times. Measure the distance

between the release bearing and the clutch brake. The

correct distance should be 12.7-14.2 mm (0.500-.560 in)

(Figure 7-30).

4. To adjust, remove cover plate and disassemble grease

hose/fitting inside.

5. Depress clutch and turn adjusting nut. Clockwise moves

the bearing toward transmission, (Figure 7-31)

NOTE: 2-1/3 rotations = 3 mm (1/8 in)

6. Clutch brake squeeze should begin 12.7-25.4 mm (0.50-

1.00 in) above the end of pedal stroke. Insert a 0.25 mm

(0.010 in) feeler gauge between the release bearing and

the clutch brake (Figure 7-32). Press the pedal down to

clamp the gauge. If the gauge does not clamp, adjust

linkage to achieve clutch brake squeeze then repeat this

step.

FIGURE 7-29

Yoke Tips

Bearing Wear Pads

3.2 mm (1/8 in)

FIGURE 7-30

Release Bearing

Clutch Brake

12.7-14.2 mm (.50-.56 in)

Transmission

Reference Only

Loading...

Loading...