Grove Published 01-29-2015, Control # 512-01 8-7

TMS700E SERVICE MANUAL UNDERCARRIAGE

Toe-In Adjustment

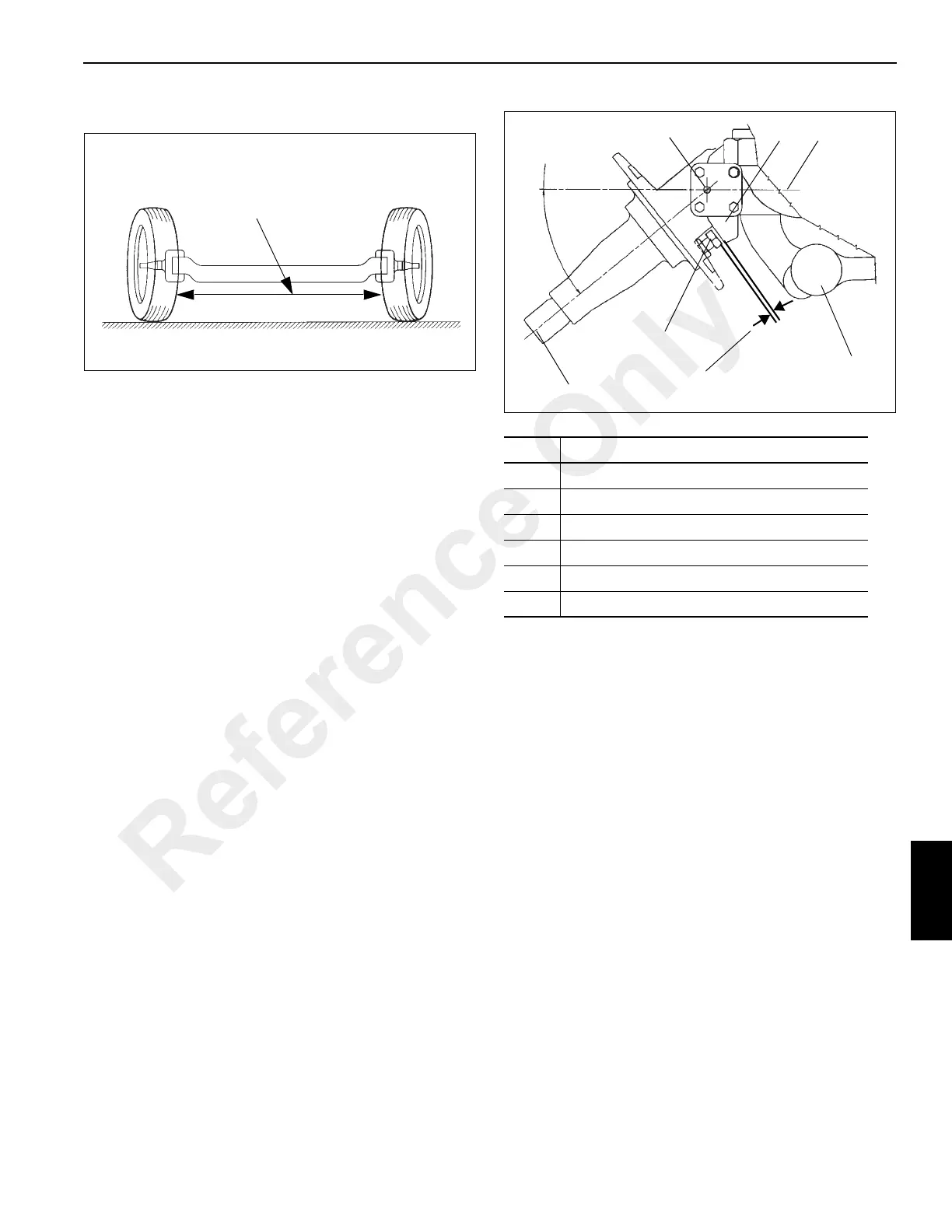

Toe-in (see Figure 8-3) is having the wheels of a steerable

axle closer together in the front than in the rear. Toe-in is

necessary for both tire wear and to keep the wheels from

weaving side to side.

1. Position the wheels straight ahead.

2. Loosen the clamps on the tie rods.

3. Adjust the tie rod as needed to provide between 0.0 to

1.5 mm (0 to 0.06 in) of toe-in for each wheel. Double

check to ensure both wheels have the correct toe-in.

4. Position the clamps on the tie rod beams so that they

clear the axle when the wheels are turned. Tighten the

clamps and recheck toe-in measurement.

Axle Stop Settings

1. Remove and discard the axle stop bolts on the last front

axle.

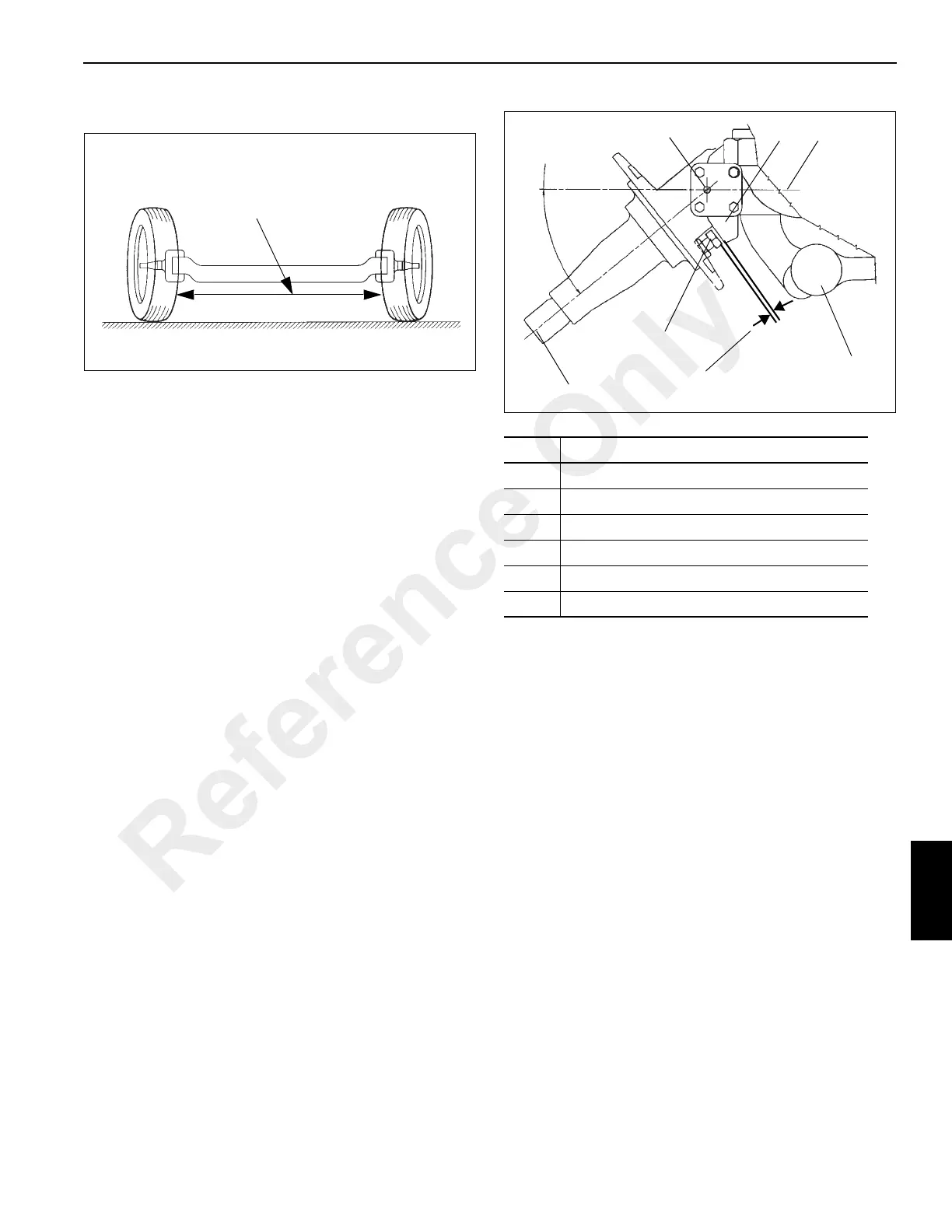

2. Adjust the axle stop bolts (see Figure 8-4) on the first

front axle, the bolts should be adjusted in or out as

needed to obtain a measurement of 3.0 mm (0.12 in)

minimum from the rigid axle stop to the top of the bolt

head (see Figure 8-4).

Drag Link Installation and Axle Synchronization

NOTE: All detail numbers are in reference to Figure 8-5.

1. Assemble front relay arm (Detail #9) and drag link (Detail

#7). Install the assembly on the carrier frame.

2. Attach rear relay arm (Detail #8) to the opposite end of

drag link (Detail #7) and then install the relay arm on the

carrier frame.

NOTE: It is acceptable to use a 21/64 drill bit as the rig

pin(s).

3. Install a 8.33 mm (0.328 in) diameter rig pin through the

front relay arm mounting bracket and the front relay arm.

Adjust drag link (Detail #7) so that a 8.33 mm (0.328 in)

rig pin can be installed through the rear relay arm

mounting bracket and the rear relay arm.

4. Check that the front wheels are aligned to the straight

ahead position by using a straight edge long enough to

lay across the wheel mounting surfaces of both front

axles. Adjust drag links (Detail #5) to fit between the

relay arms (Details #8 and #9) and the axle steer arms.

5. Check the position of the pitman arm on the steering

gearbox and adjust if necessary. Attach drag link (Detail

#6) to the pitman and adjust its length as needed to fit

between the pitman arm and the front relay arm (Detail

#9) while keeping the pitman arm position fixed.

Tire front distance is less

than tire rear distance as

measured on the axle center

line. (1.5 mm or 0.06 in

difference)

FIGURE 8-3

Item Description

1 Spindle

2 King Pin Center

3 Rigid Axle Stop

4 C/L Of Axle

5Tie Rod

6 Axle Stop Bolt

Cramp Angle

3.0 mm (0.12 in)

minimum

FIGURE 8-4

1

6

5

4

3

2

Reference Only

Loading...

Loading...