HYDRAULIC SYSTEM TMS700E SERVICE MANUAL

2-24 Published 01-29-2015, Control # 512-01

6. With the boost switch on, attempt to hoist up with the

engine running at full RPM. Adjust the main directional

control valve hoist up, port relief B, to 241 ± 4 bar (3500

± 50 psi).

7. With the boost switch on, attempt to hoist down with the

engine running at full RPM. Adjust the main directional

control valve hoist down, port relief A, to 241 ± 4 bar

(3500 ± 50 psi).

8. Reconnect the hose to port A of the hoist motor control

valve and reconnect the hoist brake release line on the

hoist.

9. If the auxiliary hoist is installed, repeat steps 3 through 8

for the auxiliary hoist and its port reliefs.

10. Completely retract the lift cylinder, attempt to lift down

with the engine running at full RPM. The gauge should

read 138 + 48/-0 bar (2000 +700/-0 psi). This relief

valve is non-adjustable.

11. Completely retract the boom. Try to telescope in with

engine running at full RPM. Adjust the main directional

control valve telescope, port B relief, to 241 ± 4 bar

(3500 ± 50 psi).

12. Completely extend the boom. Try to telescope out with

engine running at full RPM. Adjust the main directional

control valve telescope, port A relief, to 186 ± 4 bar

(2700 ± 50 psi).

13. Remove pressure gauge from the load sense test port

and reinstall cap.

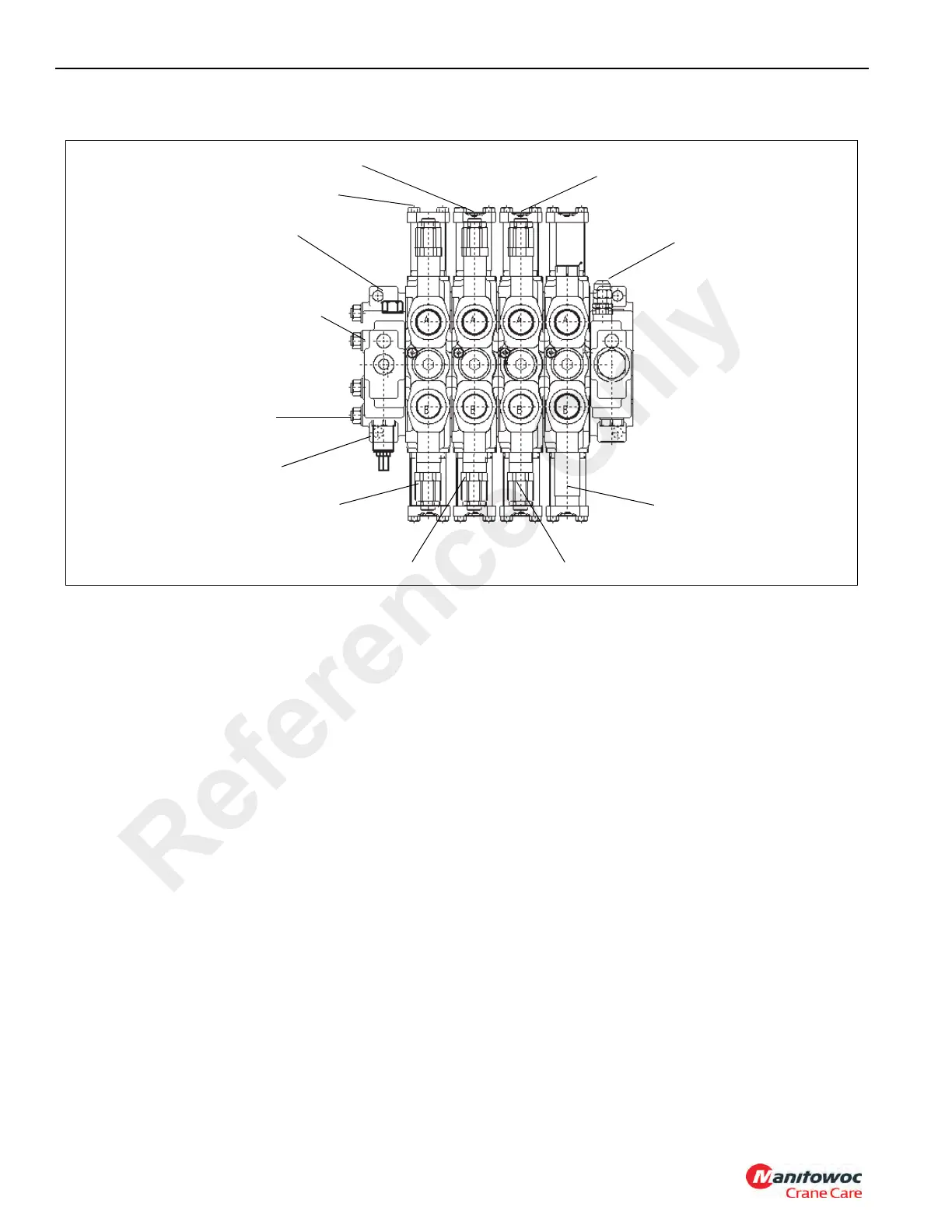

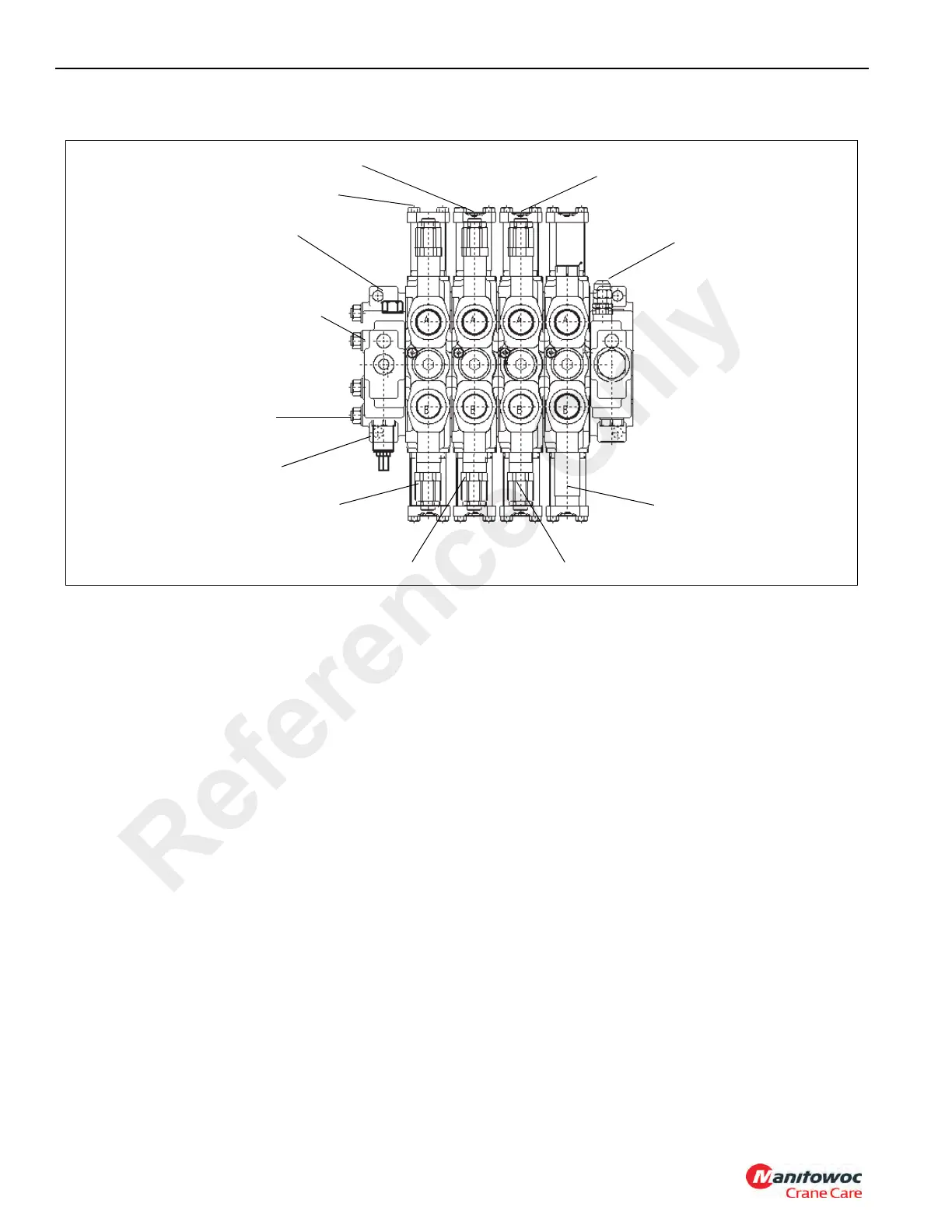

Procedure for Checking Main Directional

Control Valve Pilot Supply Pressure

1. Remove cap and install pressure gauge on pilot supply

test port per Figure 2-8.

2. Adjust the pressure reducing cartridge located in the

inlet of the hoist/lift/telescope directional control valve to

22 to 31 bar (325 to 450 psi). Turn adjustment clockwise

to increase or counterclockwise to decrease the

pressure setting.

3. Remove pressure gauge from the pilot supply test port

and reinstall cap.

Procedure for Checking Swing Brake Pilot

Supply Pressure

1. Remove and install pressure gauge on the swing brake

pilot supply valve test port per Figure 2-9.

2. Adjust pressure reducing valve cartridge to 17

+4/-0 bar

(250 +50/-0 psi). At idle, pressure should read a

minimum of 17 bar (250 psi) to ensure brake is released

for swing operation at idle.

FIGURE 2-8

Lift Down Port Relief

Aux Hoist Up Port Relief

Main Hoist Up Port Relief

Load Sense Relief

Telescope Extend Port Relief

Aux Hoist Down Port Relief

Main Hoist Down Port Relief

Load Sense Relief Test Port

Pilot Supply Test Port

Inlet Gauge Port

Telescope Retract Port Relief

Pilot Supply Pressure

Reducing Cartridge

Reference Only

Loading...

Loading...