HYDRAULIC SYSTEM MLC165-1 SERVICE/MAINTENANCE MANUAL

2-22

Published 05-26-17, Control # 238-02

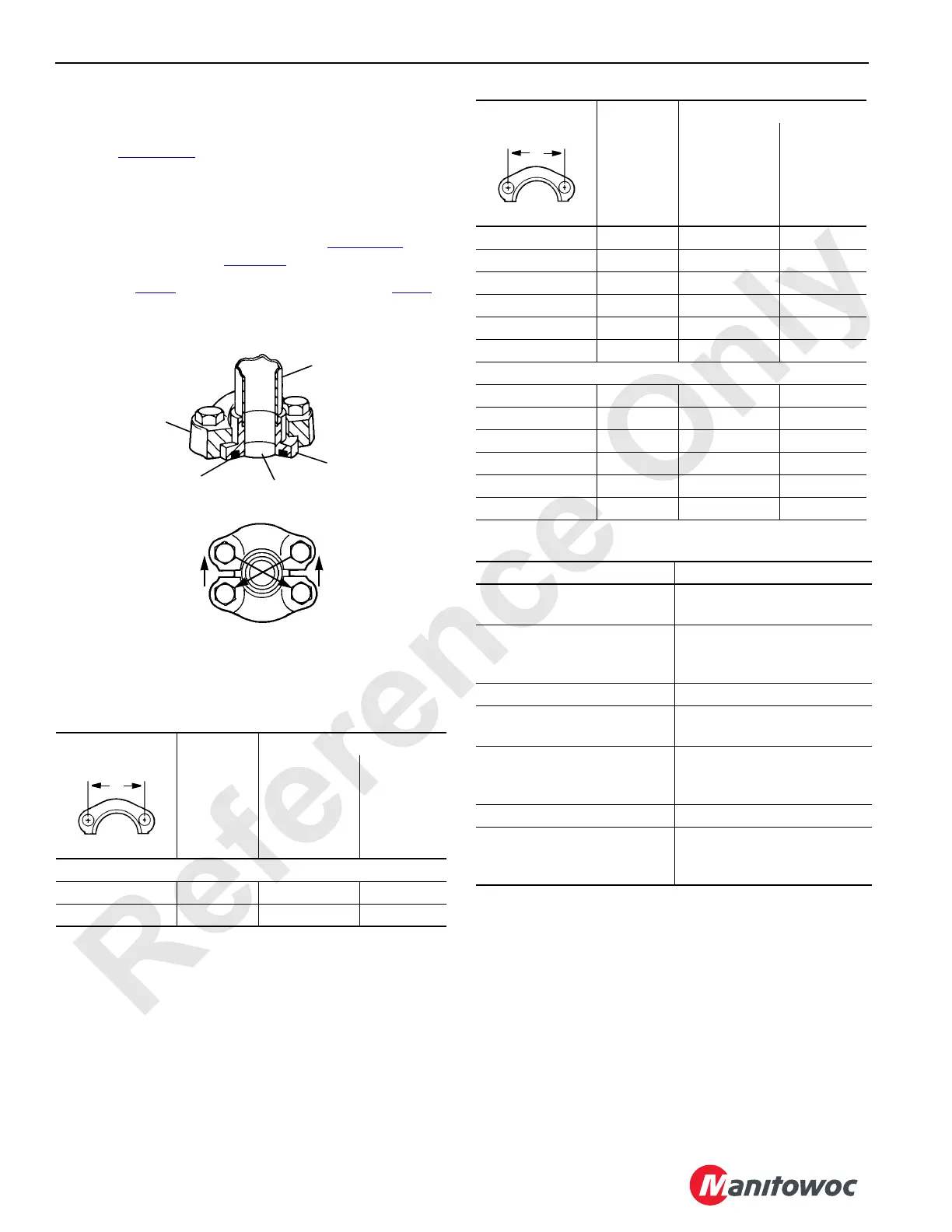

Split Flange Connection

1. Lubricate and install the O-ring in the shoulder groove

(see Figure 2-22

). Align the shoulder with the port and

assemble the flanges over the shoulder.

NOTE Bolts used must be grade-5 or better. A grade-5

bolt has three dashes in the head.

2. Snug the bolts in a diagonal manner (Figure 2-22

) to 1/3

of the torque given in Table 2-7

.

3. Repeat step 2

to 2/3 of the final torque. Repeat step 2 to

the final torque.

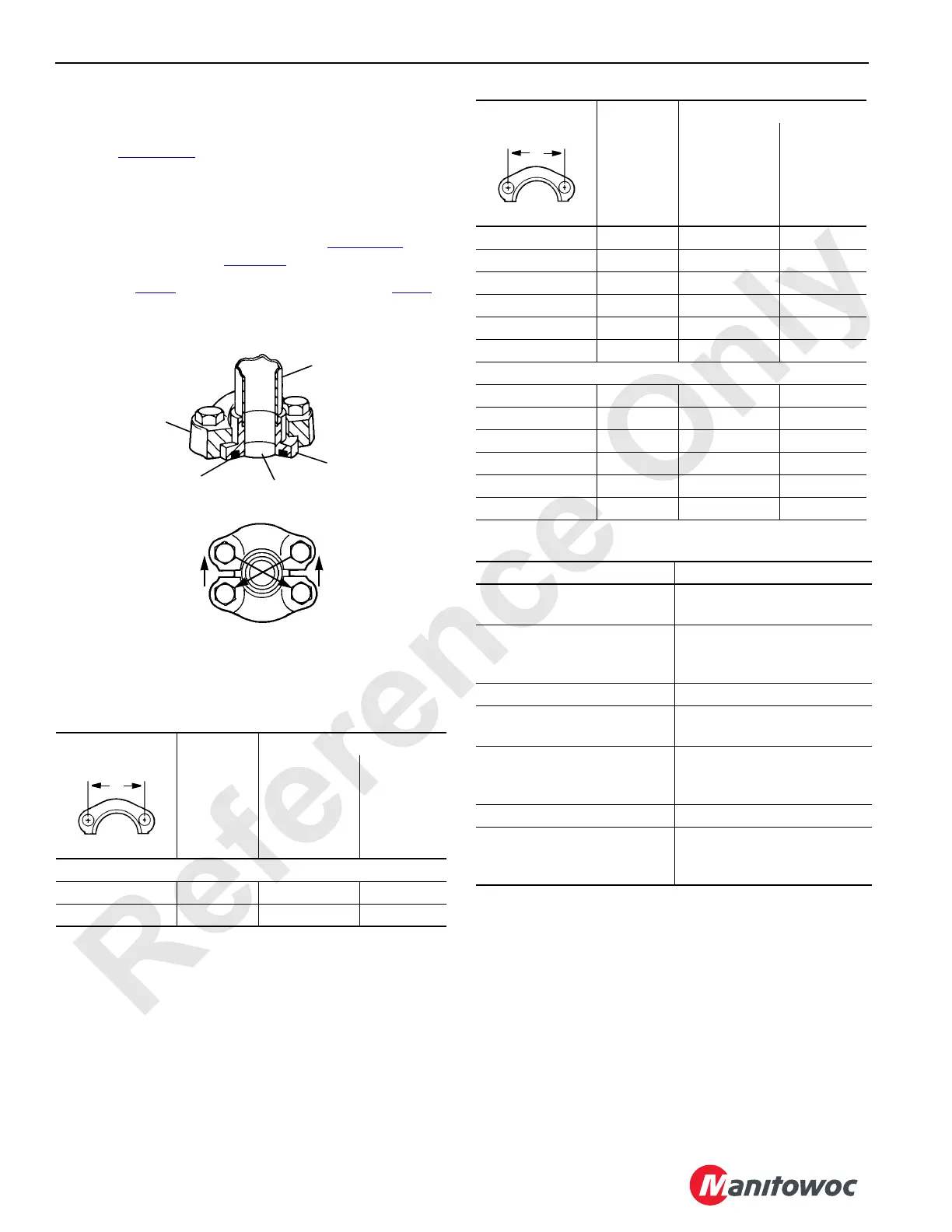

Table 2-7 Split Flange Assembly Torque

Table 2-8 Split Flange Connection Repair

A Dimension

inch (mm)

Flange

Size

Torque

in-lb Nm

Standard Pressure Series

1-1/2 (38,1) -08 175 – 225 20 – 25

1-7/8 (47,6) -12 225 – 350 25 – 40

Port

Shoulder

Flange

O-Ring

Figure 2-22. Split Flange Connection

1

2

3

4

Tube

S101

S104

2-1/16 (52,4) -16 325 – 425 37 – 48

2-15/16 (74,6) -20 425 – 550 48 – 62

2-3/4 (69,9) -24 550 – 700 62 – 79

3-1/16 (77,8) -32 650 – 800 73 – 90

3-1/8 (79,4) -24 1400 – 1600 158 – 181

3-13/16 (96,8) -32 2400 – 2600 271 – 294

High Pressure Series

1-9/16 (39,7) -08 175 – 225 20 – 25

2 (50,8) -12 300 – 400 34 – 45

2-1/4 (57,2) -16 500 – 600 57 – 68

2-5/8 (66,7) -20 750 – 900 85 – 102

3-1/8 (79,4) -24 1400 – 1600 158 – 181

3-13/16 (96,8) -32 2400 – 2600 271 – 294

Causes Cures

Flanges not tight

Tighten the bolts evenly to

proper torque

Flanges tightened unevenly

causing extrusion of the O-

ring

Replace the O-rings.

Tighten bolts evenly to

proper torque

O-ring cut Replace

O-ring the wrong size

Replace with the proper

size

Sealing surfaces not

smooth; scratched or

gouged

Repair if possible or

replace parts

Sealing surfaces dirty Clean

Flanges keep getting loose

in service

Use SAE grade 5 bolts or

better. Retighten the bolts

after system is hot

A Dimension

inch (mm)

Flange

Size

Torque

in-lb Nm

Loading...

Loading...