Operating Instructions – Labmaster

©

130 and MB20G Systems

Instruction Manual

Chapter 6: Installation Requirements

© MBraun, Inc. Edition 1/2007 Page 6-1

CHAPTER 6: INSTALLATION REQUIREMENTS

6.1 Location

The room in which the glovebox will be used should be dry and well ventilated with a

temperature between 59°F and 86°F (15°C to 30°C). The floor should be level and stable

enough to support the weight of the glovebox system.

Position the glovebox in an area that allows the user to have adequate working space in and

around the system (e.g. gloveports, antechamber(s), etc.). If positioned against or near a wall,

the clearance should be a minimum of approximately 24 inches (600 mm) for the rear and side

of the glovebox without antechamber(s).

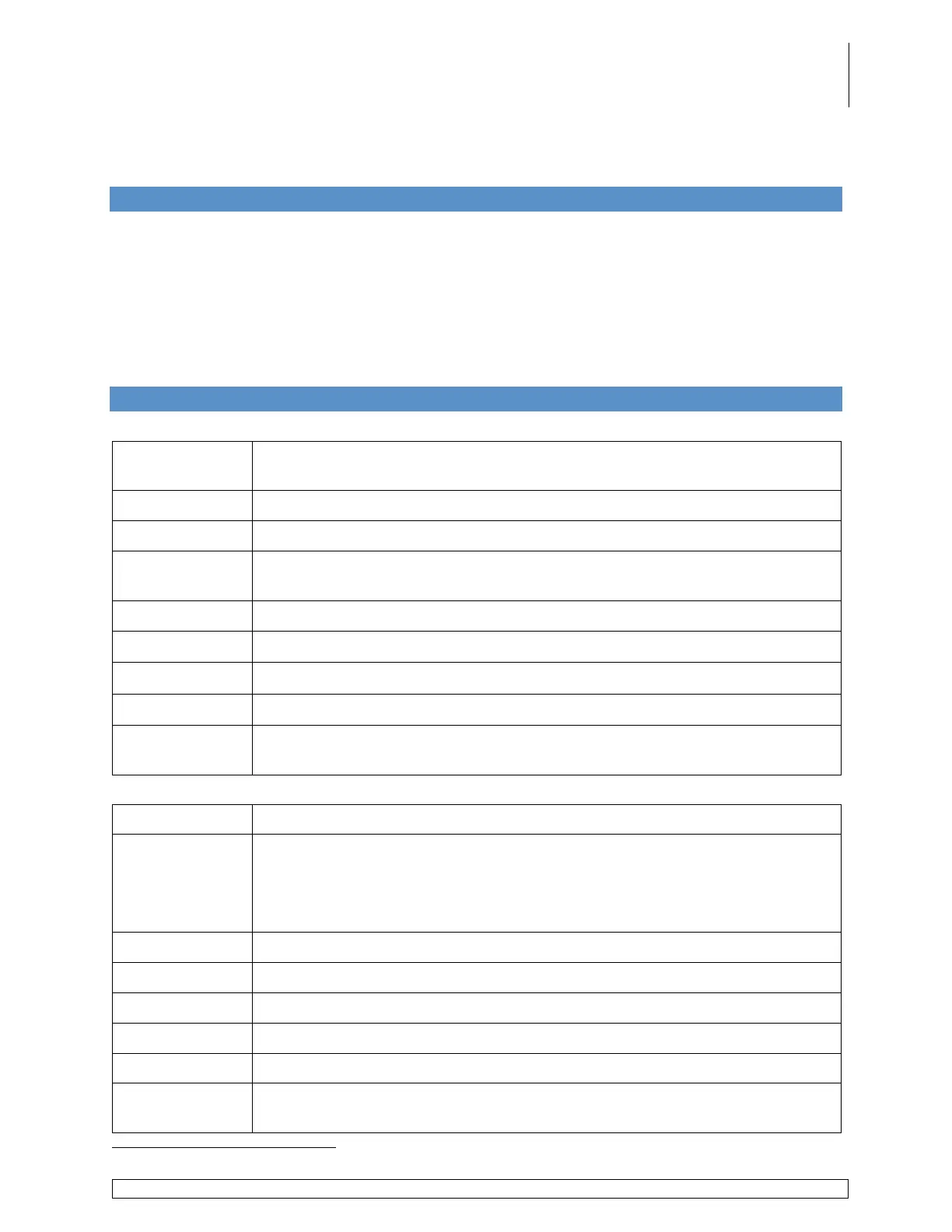

6.2 Gas Supply and Connection Requirements

Working Gas

Use:

To establish and maintain the ultra pure gas atmosphere. Used as the

operating gas for electropneumatic valves.

Gas Type:

Nitrogen, Argon, Helium supplied at 80psi.

Purity:

Industrial grade or better; from tanks or other facility gas supply source.

Quantity:

Permanent supply for the system’s operation (e.g. pressure compensation,

etc.).

Regulator Type: Two (2) stage with a 0 – 100psi gauge.

Pressure:

80psi

Flow rate:

200 liters/minute

Material:

3/8” Braided Tygon™ hose (supplied with the system).

Connections:

¼” male NPT to 3/8” O.D. hose barb (connects Tygon™ hose to gas

regulator).

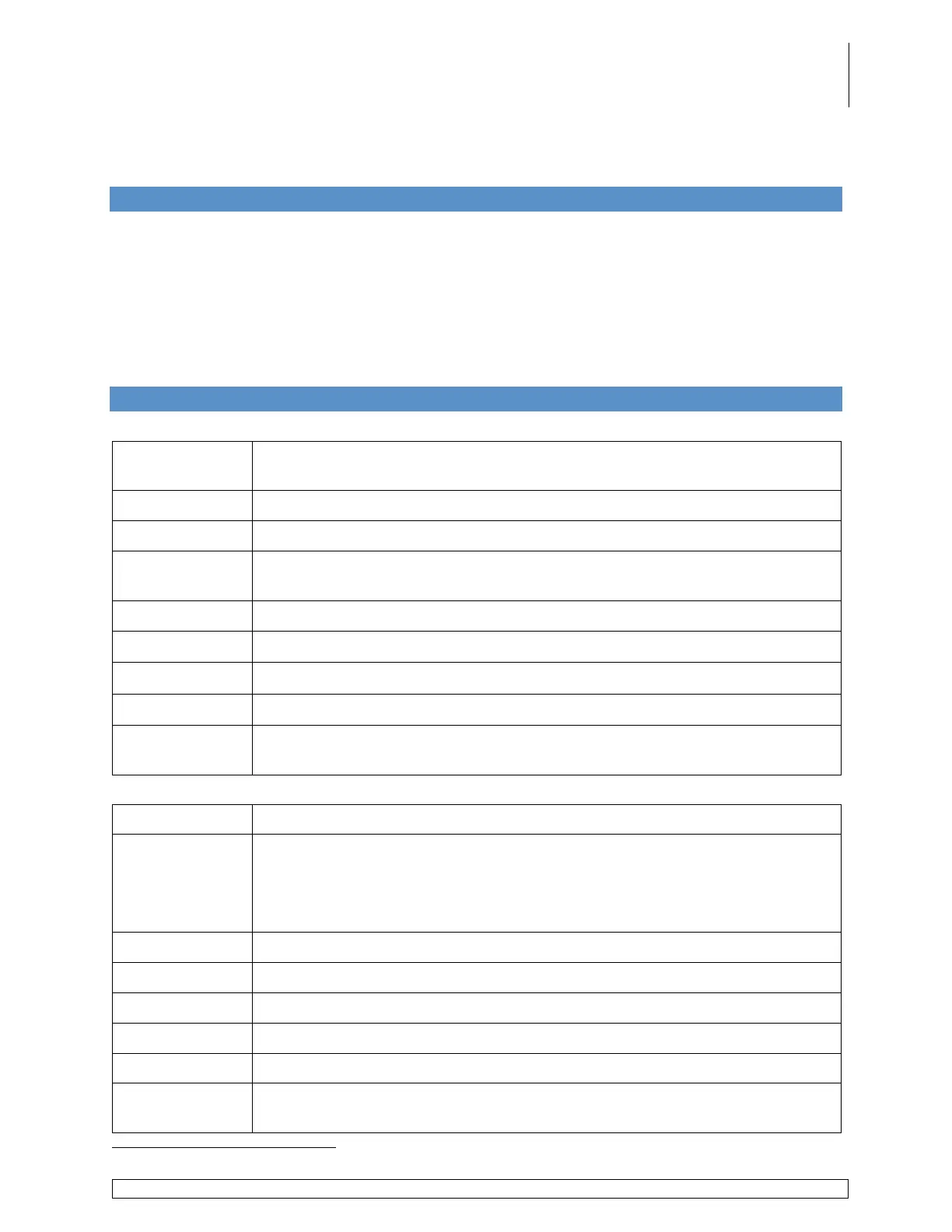

Regeneration Gas

Use: Reprocessing saturated purifier columns.

Gas Type

1

:

Nitrogen as the Working Gas: 90-97% Nitrogen with 3-10% Hydrogen

balance

Argon as the Working Gas: 90-97% Argon with 3-10% Hydrogen balance

Helium as the Working Gas: 90-97% Helium with 3-10% Hydrogen balance

Quantity:

Approximately 3,500 liters for each regeneration process.

Regulator Type:

Two (2) stage Hydrogen regulator with a 0 – 20psi gauge.

Pressure:

5psi

Flow Rate:

15 – 20 liters/minute

Material:

3/8” Braided Tygon™ hose (supplied with the system).

Connection:

¼” male NPT to 3/8” O.D. hose barb (connects Tygon™ hose to gas

regulator).

1

Gas combination will vary depending upon the type of working gas used based on user’s application.

Loading...

Loading...