Document reference MAMPS-HW/E HARDWARE MANUAL

Edition 18 - March 2022 VM600 machinery protection system (MPS)

7-11

Position measurement

PROCESSING MODES AND APPLICATIONS

Similarly, if the sensors are installed and measure in opposite directions or one has a

reversed polarity ( ), then:

• AS = BBAB − RS (that is, the signals must be subtracted).

• So in the Absolute shaft vibration (AS) processing function, the angle between the two

sensors must be configured as 180°.

It is worth noting that the original BBAB and RS outputs (values and alarms) are also

available from their respective single-channel processing functions (see Figure 7-6) for use

by the machinery monitoring system.

NOTE: It should be remembered that when a signal is integrated, the output signal lags

the input signal by 90° (that is, the output signal is 90° behind the input signal). This

is automatically considered by any digital integration performed by an MPC4 card.

7.6 Position measurement

(1) Description

The relative position of a shaft can be measured by placing a proximity probe on the bearing.

This type of measurement is particularly applicable to fluid-film thrust bearings where it is

necessary to measure the axial motion of the shaft relative to the bearing.

The following front-end components are the most commonly used:

• TQxxx proximity transducer + IQSxxx signal conditioner

• TQxxx proximity transducer + IQSxxx signal conditioner + (Intrinsically safe) GSVxxx

power supply and safety barrier (applications).

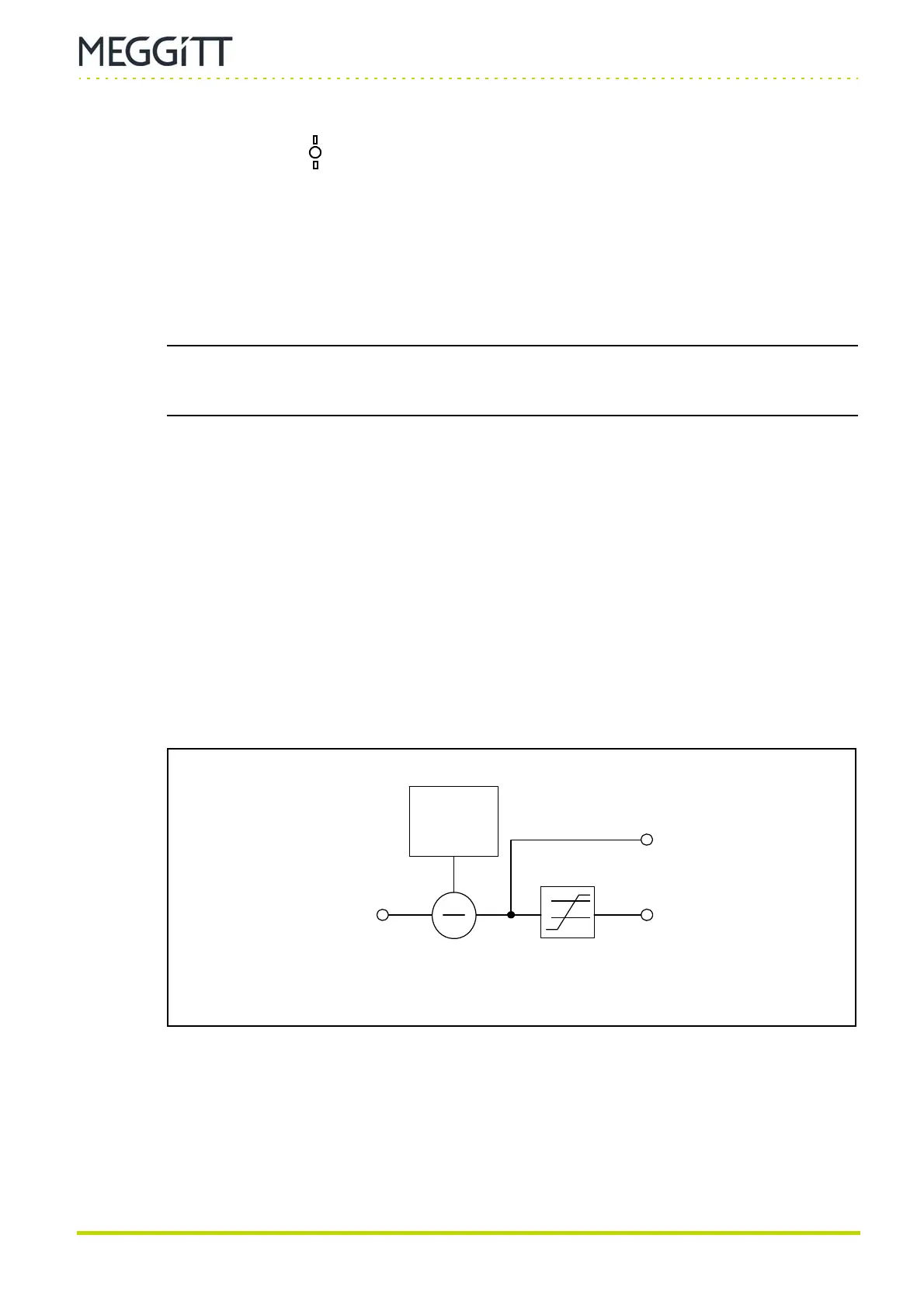

(2) Block diagram

With a proximity probe connected to the MPS, the position processing function calculates the

position of the target relative to a reference point.

The initial target position (gap) must be stored (or configured). This will be used as a

reference position for measurement purposes. This value ( X

initial

) depends on the physical

probe placement, and must be subtracted from the measured value ( X

in

) in order to give

the target position relative to the reference position:

X

out

= X

in

− X

initial

Figure 7-7: Block diagram showing position processing

Position value

( X

out

)

Alarms

Position input

( X

in

)

Initial gap

(X

initial

)

Loading...

Loading...