Document reference MAMPS-HW/E HARDWARE MANUAL

Edition 18 - March 2022 VM600 machinery protection system (MPS)

10 - 7

Connecting sensors to the IOC8T

CONFIGURATION OF AMC8 / IOC8T CARDS

10.2.2 Connecting thermocouples

The operating principle of a thermocouple (TC) is based on the Seebeck effect. If two

dissimilar metal wires are soldered together at one end (the “hot” junction), a voltage in the

mV range will be generated across the free ends (the “cold” junction). This voltage is

proportional to the difference in temperature between the hot and cold junctions. The

temperature of the cold junction should be measured by another sensor (preferably a RTD

device) and this signal is then used for compensation purposes. This technique is known as

cold-junction compensation (CJC).

The hot junction is placed at the measuring point. The cold junction should ideally be on a

terminal strip placed in an isothermal box, that is, one in which there is a negligible

temperature difference between the junctions on the terminal pins, creating a negligible

voltage error.

Another temperature sensor measures the internal temperature of the box, near the terminal

strip. This is processed by another channel on the AMC8 card and used for cold junction

compensation (2 out of the 8 channels on the AMC8 can be configured for CJC purposes

using the VM600 MPSx software).

When cold-junction compensation (CJC) is used with a thermocouple (TC) device,

temperature offsets can arise between the resistance temperature detector (RTD) device

used for CJC and the thermocouple input connections if there are large temperature

differences between the inside and outside of the VM600 rack. (Temperature offsets of up to

10°C (18°F) have been reported in extreme cases.)

In practice, the temperature inside of a VM600 rack can be higher than the temperature

outside, where the CJC RTD is installed, and the heat inside of the rack can be transmitted

to the screw-terminal connectors that connect to the thermocouple (TC), leading to an error

in reported temperature measurements that is proportional to the temperature offset.

Accordingly, when cold-junction compensation (CJC) is used with a thermocouple (TC)

device, temperature differences around a VM600 rack should be minimised, for example, by

using forced-air cooling (such as a rack-mounted fan below IOC8T cards) or a

temperature-controlled environment.

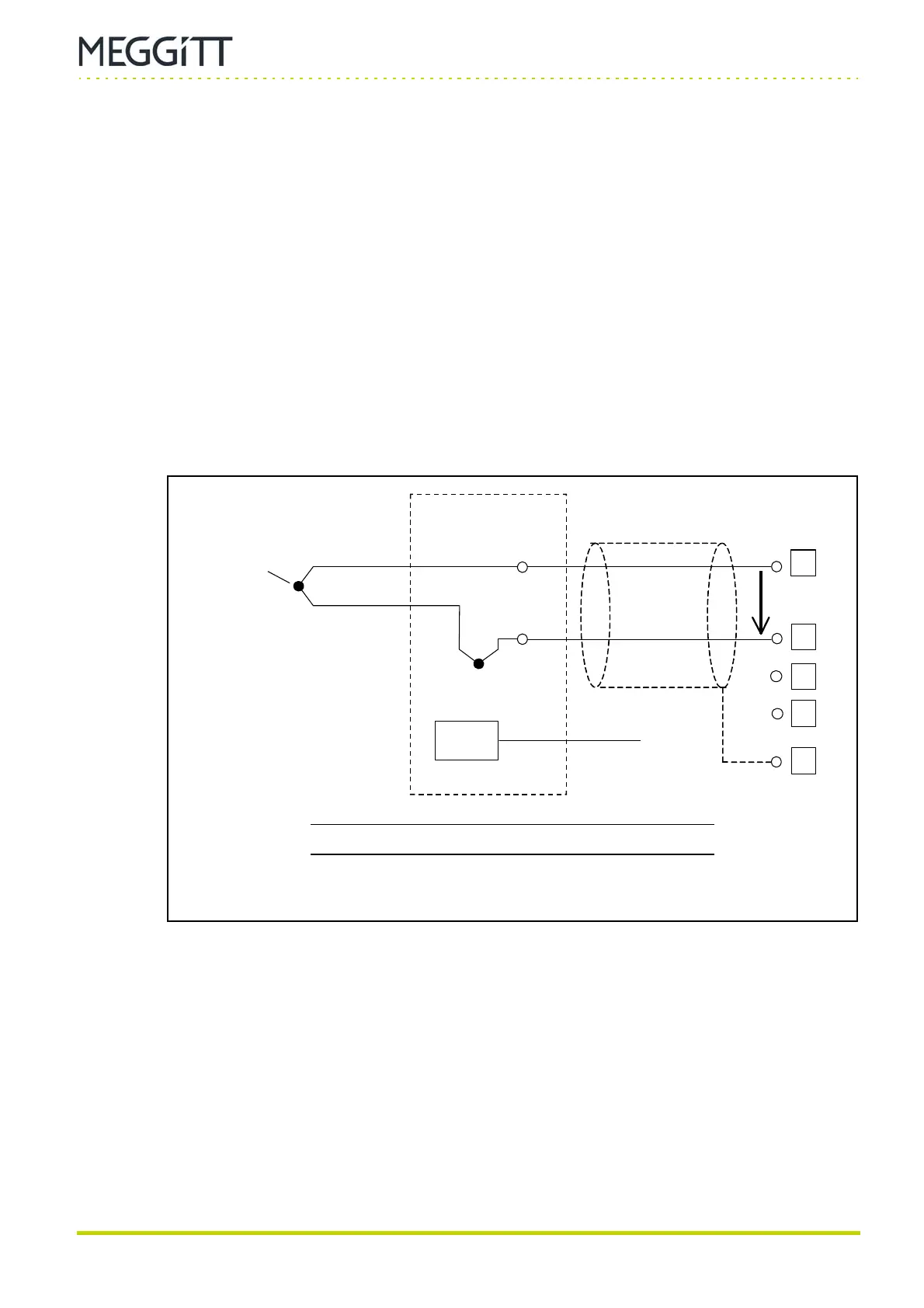

Figure 10-4: Wiring for thermocouple with CJC

Thermocouple

T

hot

T

cold

Isothermal box

Metal “B”

Metal “A”

Connect to

CJC channel

Note: Usually the cold

junction is merged with the

lower terminal (shown here

as a “white dot”).

The representation shown

here is simply for clarity.

Hot junction

NOTE: The setting of jumper J805 is unimportant.

Loading...

Loading...