5C-44 - MID-SECTION 90-830234R3 DECEMBER 1997

Pressure Operated Assembly

Installation

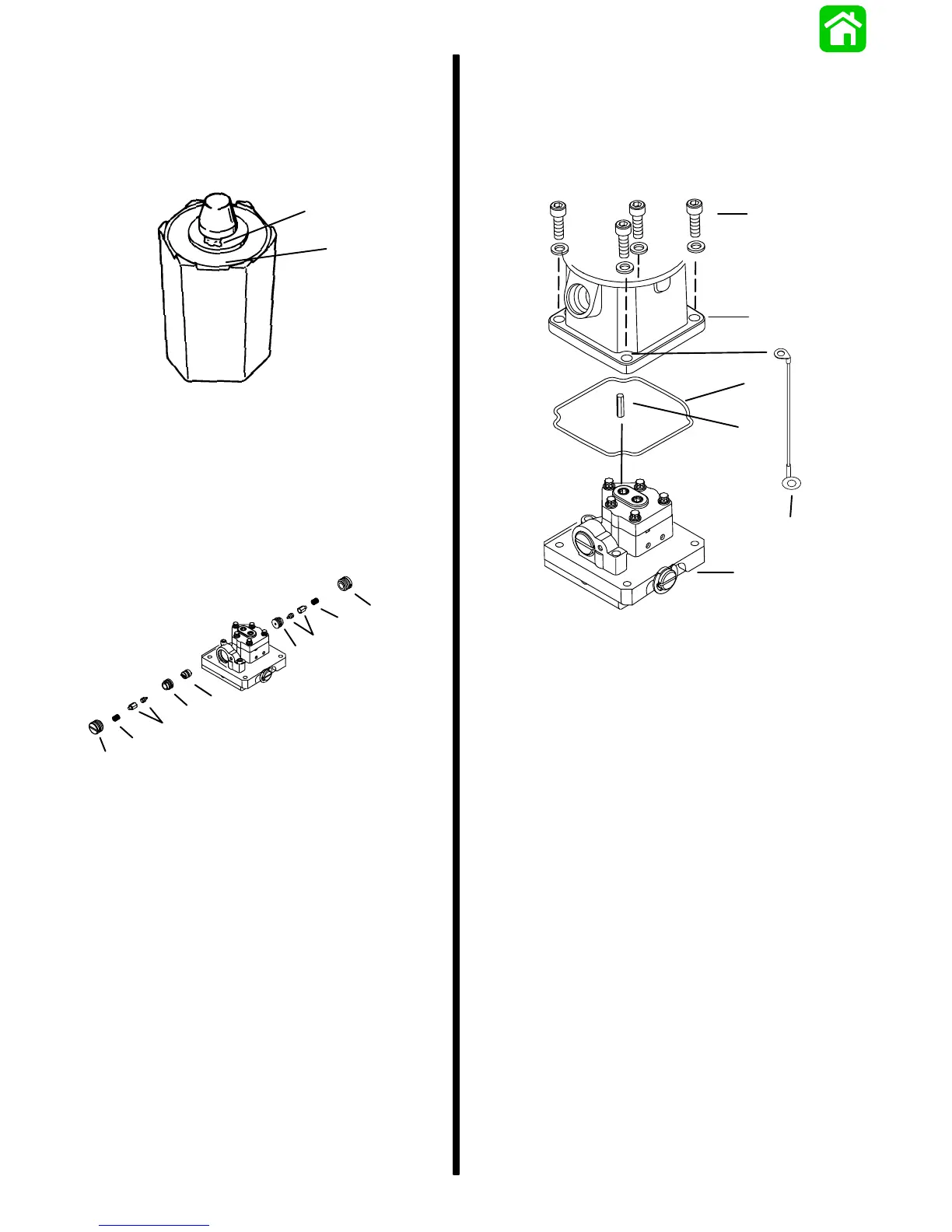

IMPORTANT: Inspect poppet assembly for debris

in the area shown. If debris is found on poppet re-

place poppet.

a

b

a - Debris Under Valve Tip

b - Rubber Seat

1. Lubricate O-rings.

2. Install spool, seat with O-ring, check valve/pop-

pet, spring and plug with O-ring into pump. Re-

peat for other side. Torque plugs to 120 lb. in.

(13.6 N⋅m).

a

a

b

d

c

c

d

e

b

a - Plug (2) Torque to 120 lb. in. (13.6 N⋅m)

b - Spring (2)

c - Check Valve/Poppet (2)

d - Seat (2)

e - Spool

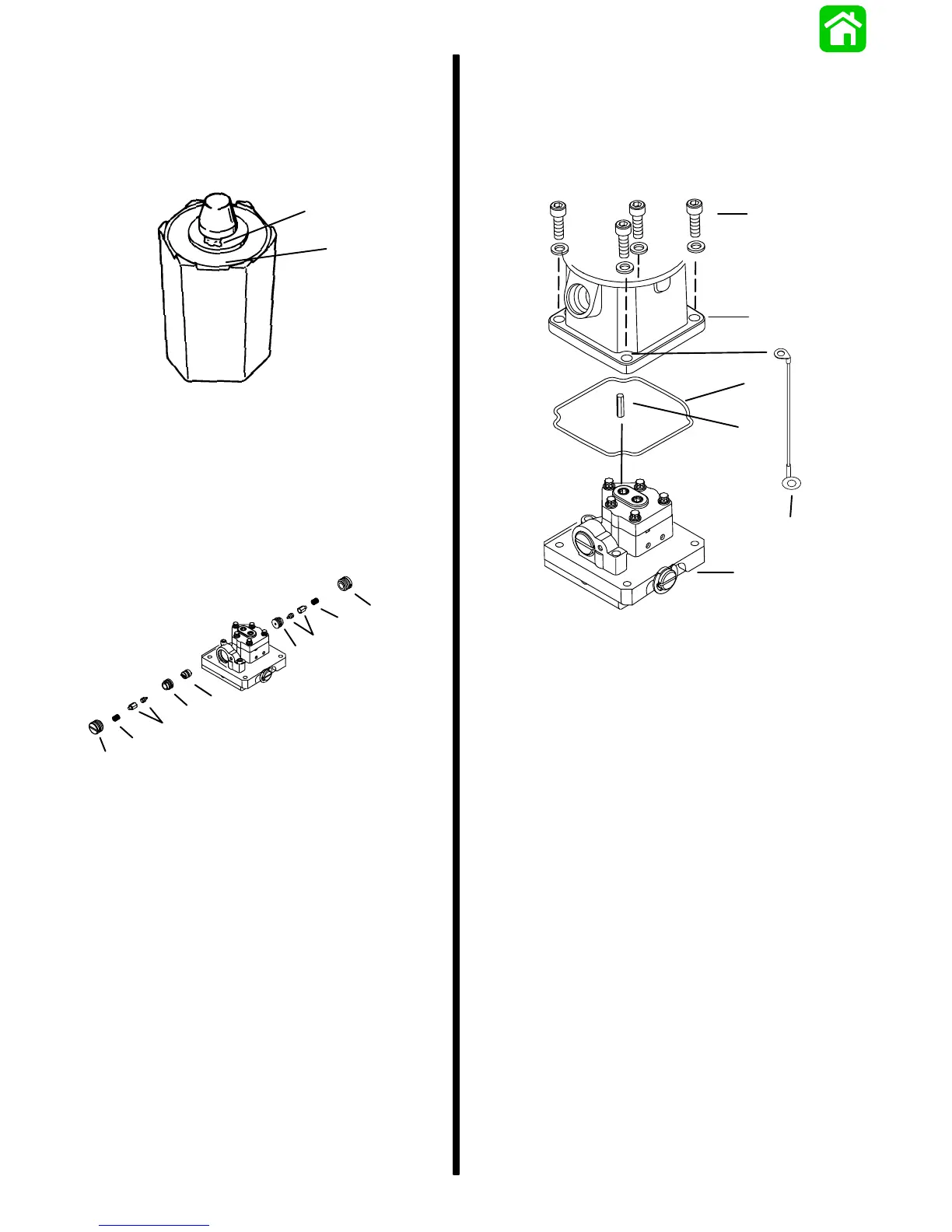

Reservoir/Motor Installation

1. Install coupler into top of pump. Make sure reser-

voir seal is in the reservoir groove and place res-

ervoir onto pump/manifold assembly. Install

ground strap under screw shown. Torque screws

to 80 lb. in. (9.0 N⋅m).

b

d

e

a

c

f

a - Screw (4) Torque to 80 lb. in. (9.0 N⋅m)

b - Reservoir

c - Reservoir Seal

d - Coupler

e - Manifold Assembly

f - Ground Strap

2. Fill reservoir to bottom of fill hole using Quicksil-

ver Power Trim Fluid (92-901000A12). If not

available, use automotive (ATF) automatic trans-

mission fluid.

Loading...

Loading...