90-830234R3 DECEMBER 1997 LOWER UNIT - 6A-27

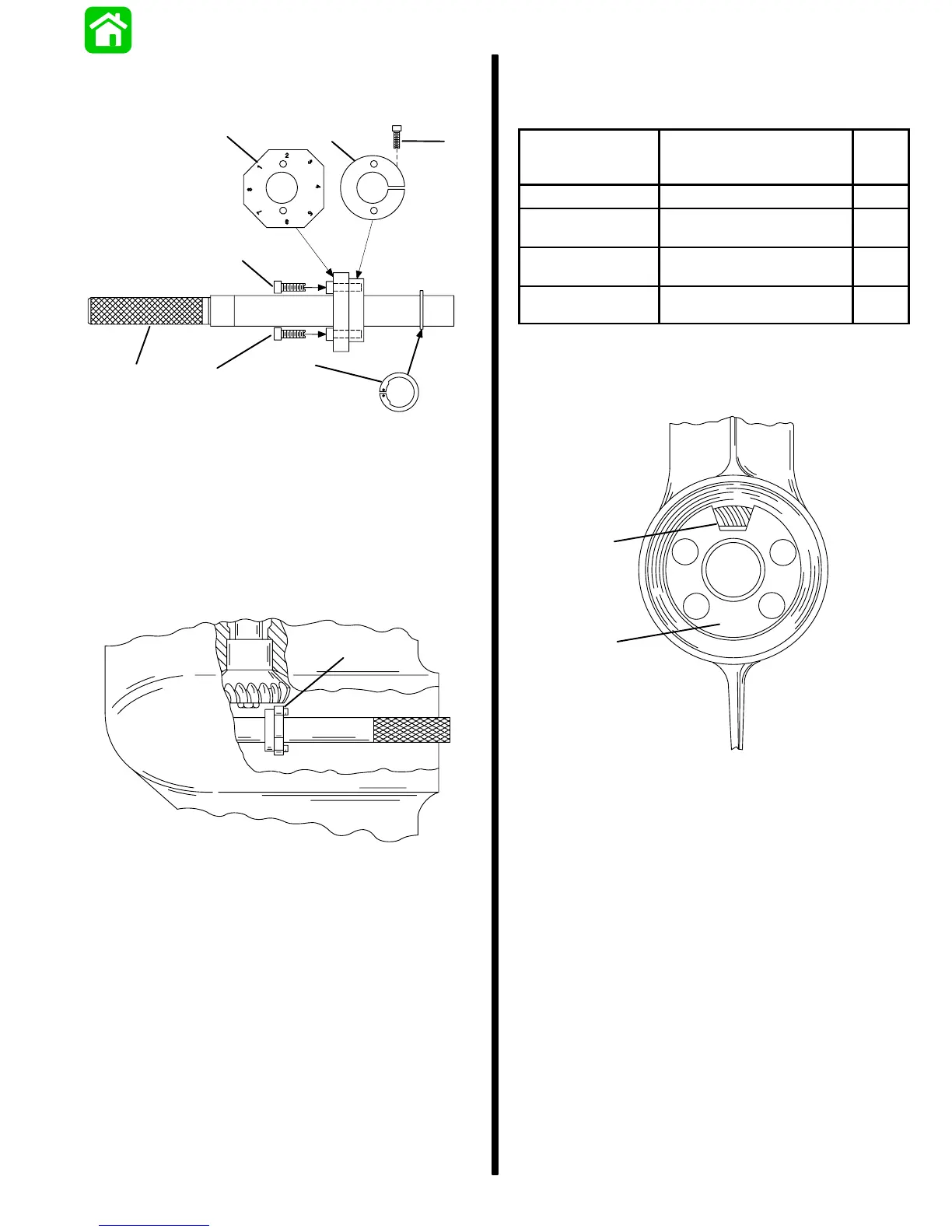

6. Assemble Pinion Gear Locating Tool (91-12349A2)

as shown; do not tighten collar retaining bolt at

this time.

b

d

e

c

ca

f

a - Arbor

b - Gauging Block; Install With Numbers Away From Split

Collar

c - Bolt; Gauging Block Retaining

d - Split Collar

e - Bolt; Collar Retaining

f - Snap Ring

7. Insert tool into forward gear assembly; position

gauging block under pinion gear as shown.

a

22067

a - Gauging Block

8. Remove tool, taking care not to change gauging

block position, and tighten collar retaining bolt.

9. Insert tool into forward gear assembly; position

proper numbered flat (from chart) of gauging

block – under pinion gear.

MODEL

GEAR RATIO

(PINION GEAR TEETH/

REVERSE GEAR TEETH)

USE

FLAT

NO.

50 Bigfoot (4-stroke) 13/30 8

60 Bigfoot/60 Sea-

pro/60 Marathon

13/30 8

75-thru-90

(3 Cylinder)

13/30 8

100/115/125

(4 Cylinder)

14/29 2

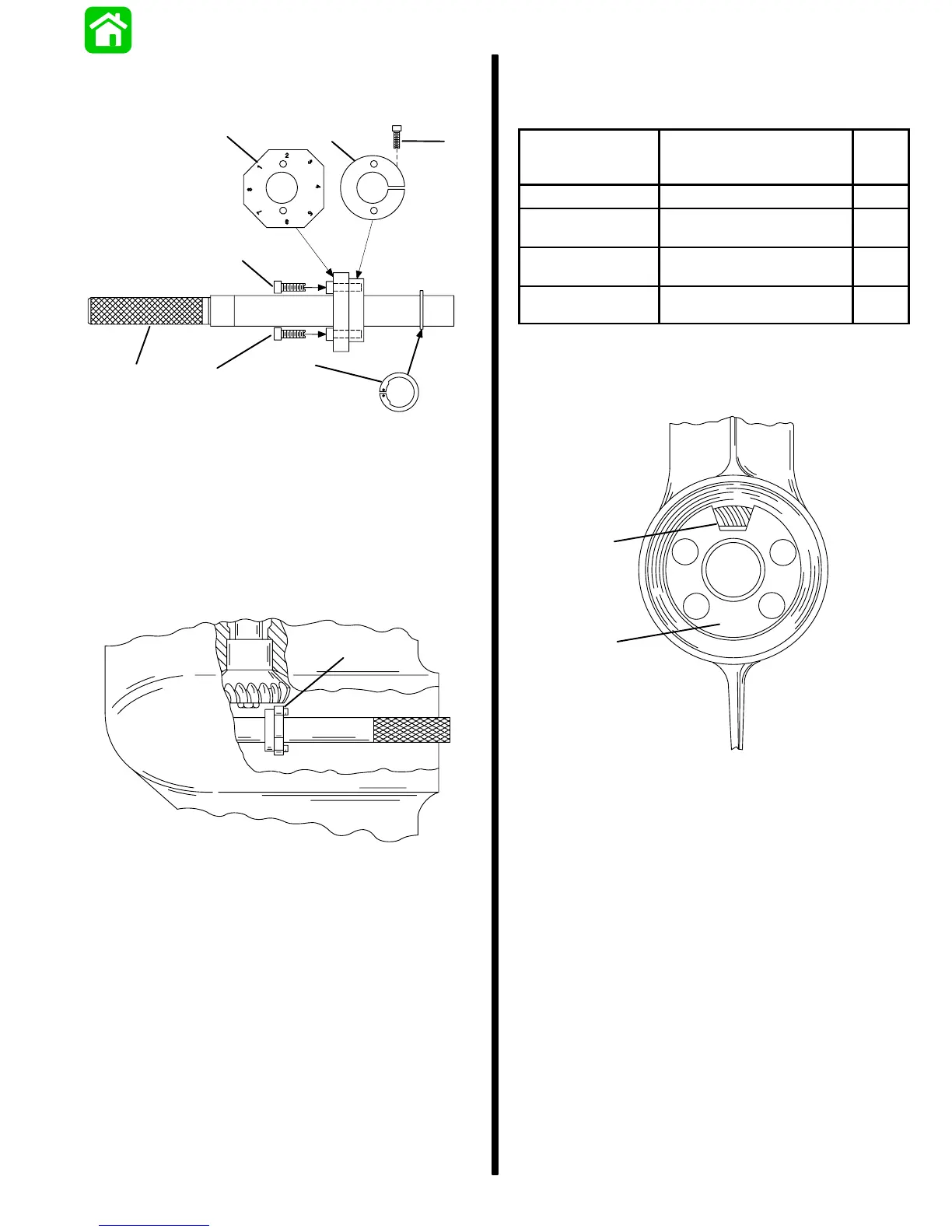

10. Install the number “3” locating disc against bear-

ing carrier shoulder in gear housing.

11. Position access hole as shown.

b

a

24643

a - Locating Disc

b - Access Hole

Loading...

Loading...