6 - ORDINARY MAINTENANCE

6 - 15

• TYRES AND STUDS BOLTS

Check that the wheel studs are tightened and the tyres are properly inflated. Inspect tires for damages or excessive wear daily.

• SAFETY BELTS

Check the presence, function and the good condition of safety belt.

WARNING!

Do not use the machine on site if the safety belt is not in efficient working condition.

EVERY 50 HOURS OR WEEKLY

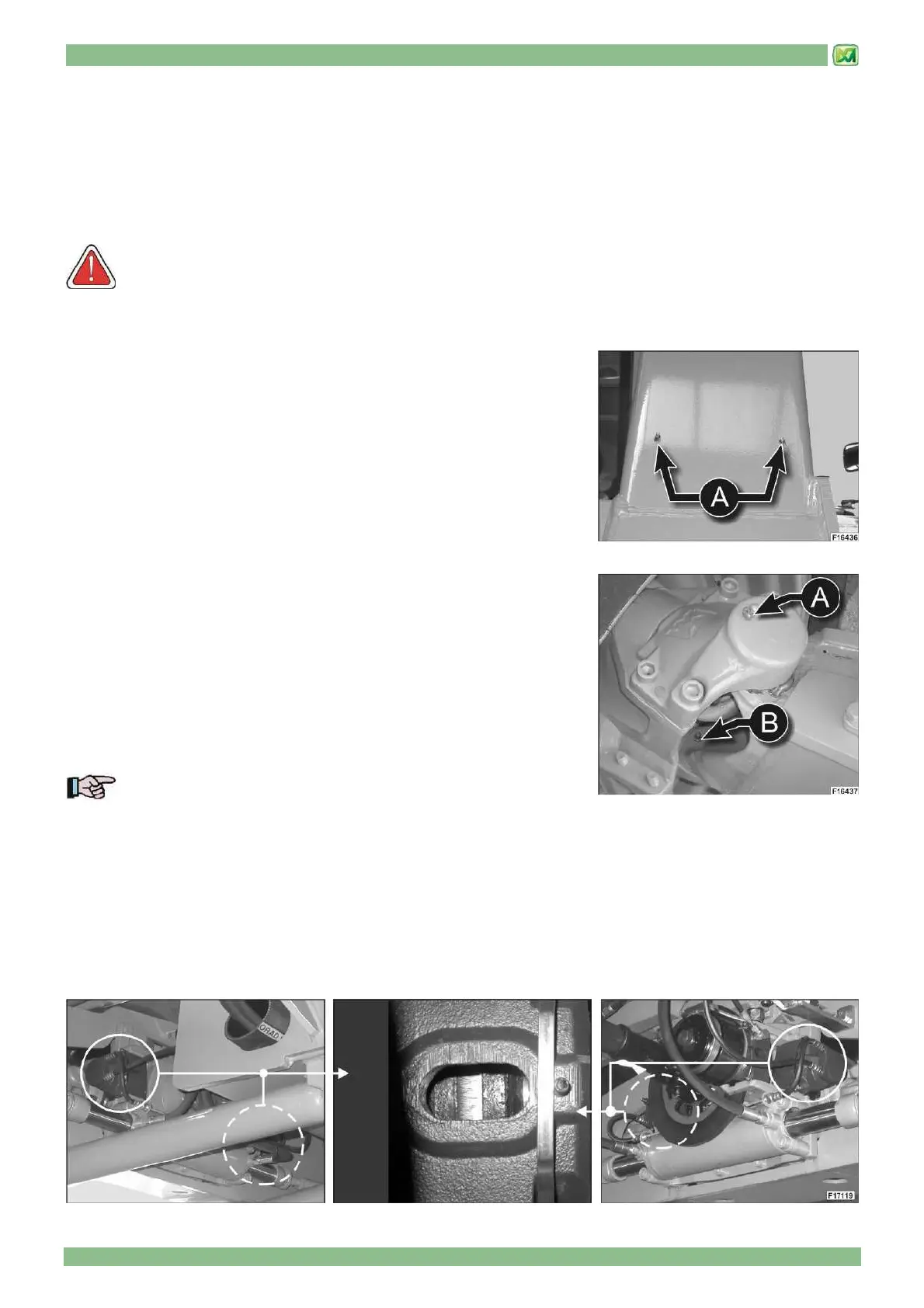

• SLIDING PADS OF THE TELESCOPIC BOOM (INNER PADS)

The internal sliding pads must be greased to guarantee optimal performance of

the telescopic boom. To carry out this operation correctly, proceed as follows:

- Fully retract the telescopic boom

- apply the specific product for the boom sliding pads (internal) with the

lubricators "A" (see paragraph "FUELS AND LUBRICANTS")

- extend and retract the boom a few times so as to evenly distribute the grease

inside the pads.

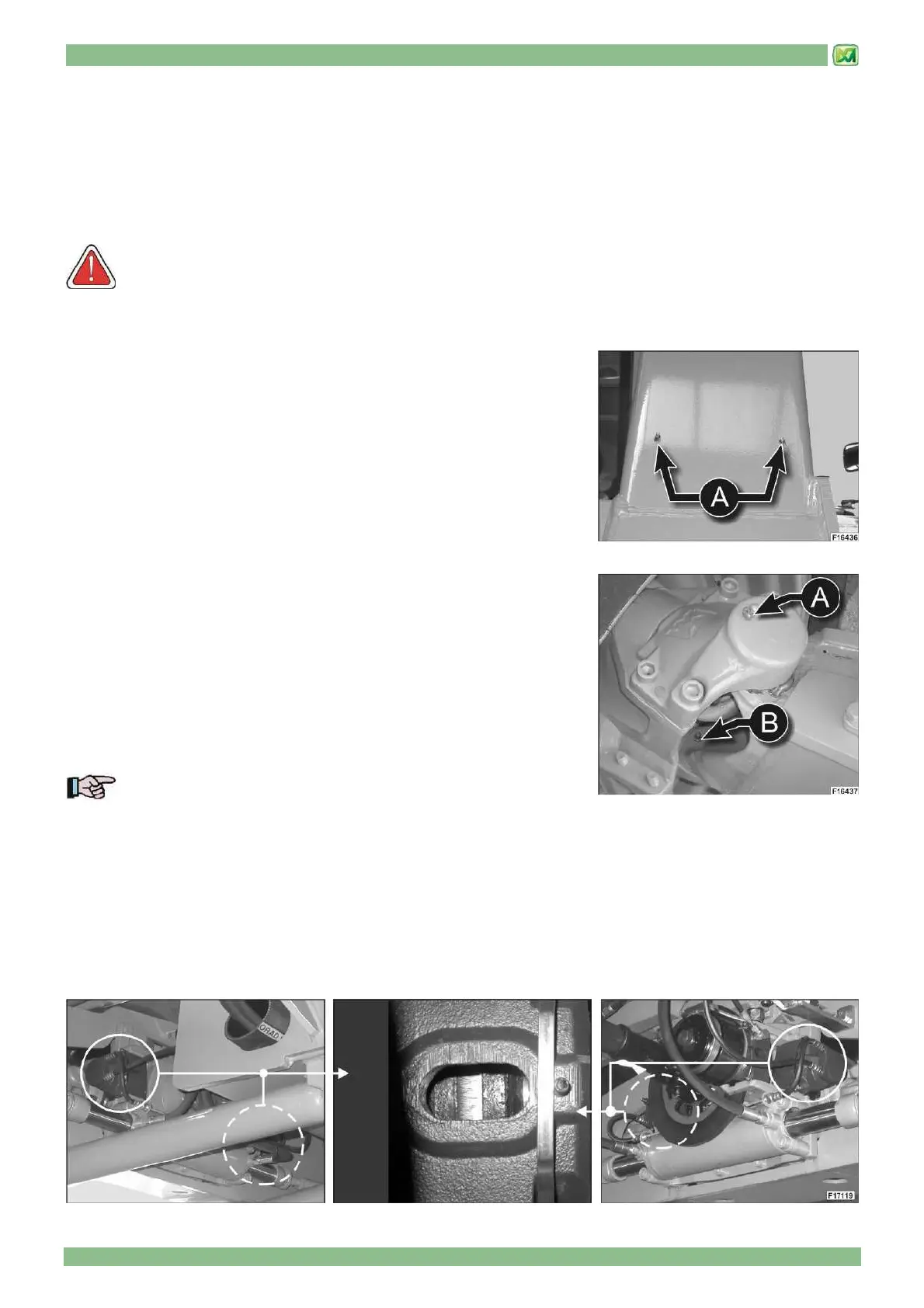

• ARTICULATED JOINT OF THE WHEEL REDUCTION HUBS

To ensure optimum performance of the wheel reduction hubs, grease them as

follows:

- stop the machine

- apply some specific grease onto the couplings of the wheel reduction hubs

through greasing points "A" and "B" until grease comes out (see section

"FUELS AND LUBRICANTS")

- repeat this operation on all the couplings of the wheel reduction hubs

- perform a few steering cycles to spread grease uniformly inside the wheel

reduction hubs

NOTE ! To facilitate the greasing of the wheel reduction hubs, it is

possible to steer the front wheels in such a way as to get a better view of the greasers "A" and "B"

• BRAKE PADS

Check the wear of break pads as follows:

- stop the diesel engine

- lie under the machine until you reach the area where brake callipers are located

- Check pads "A" on both sides of the bridge

- Repeat the operation for the other bridge

Loading...

Loading...