6 - ORDINARY MAINTENANCE

6 - 34

TROUBLE SHOOTING

Should your machine not work correctly, please refer to the following table, so as to identify and eliminate the cause of the

problem. The operator is allowed to carry out just some operations, while the most complex ones shall be carried out by Merlo

Technical Assistance service.

FAILURE CAUSE REMEDY

HYDRAULIC

SYSTEM

- Oil level is too low/too high Restore the correct oil level

- Oil type is not suitable Change the oil type

- Oil is dirty or contains water Change the oil

- Oil is cold at start Let the oil warm up

- Leak in the system Eliminate the leak

- Presence of air in the oil Eliminate air

- Hoses throttling Eliminate constriction

- Return filter is dirty/ clogged Replace the filter

Should you notice any other failures in the hydraulic system (pump, valves, cylinders, etc.),

please contact Merlo Technical Assistance service.

ELECTRICAL

SYSTEM

- Battery is flat Charge it

- Electrolyte level is low Fill it up

- Connections are slack/ rusted Restore normal conditions

- Fuses are blown Search for failure cause – Replace fuses

- Alternator belt is slack Adjust belt tension

Should you notice any other failures in the electrical equipment, please contact Merlo

Technical Assistance service.

BRAKING

SYSTEM

- Excessive brake pad wear

Replace brake pads. Please contact Merlo

Technical Assistance service

- Low brake fluid level Check the system for any leak, then fill it up

- Air in the system Purge air from the system

ENGINE

Please refer to the troubleshooting section in the Engine Manual. For any operations other

than routine maintenance to be carried out on certain parts (injection pump, injectors,

valves, etc.), please contact Merlo Technical Assistance service.

HYDROSTATIC

TRANSMISSION

For these operations please contact Merlo Technical Assistance service.

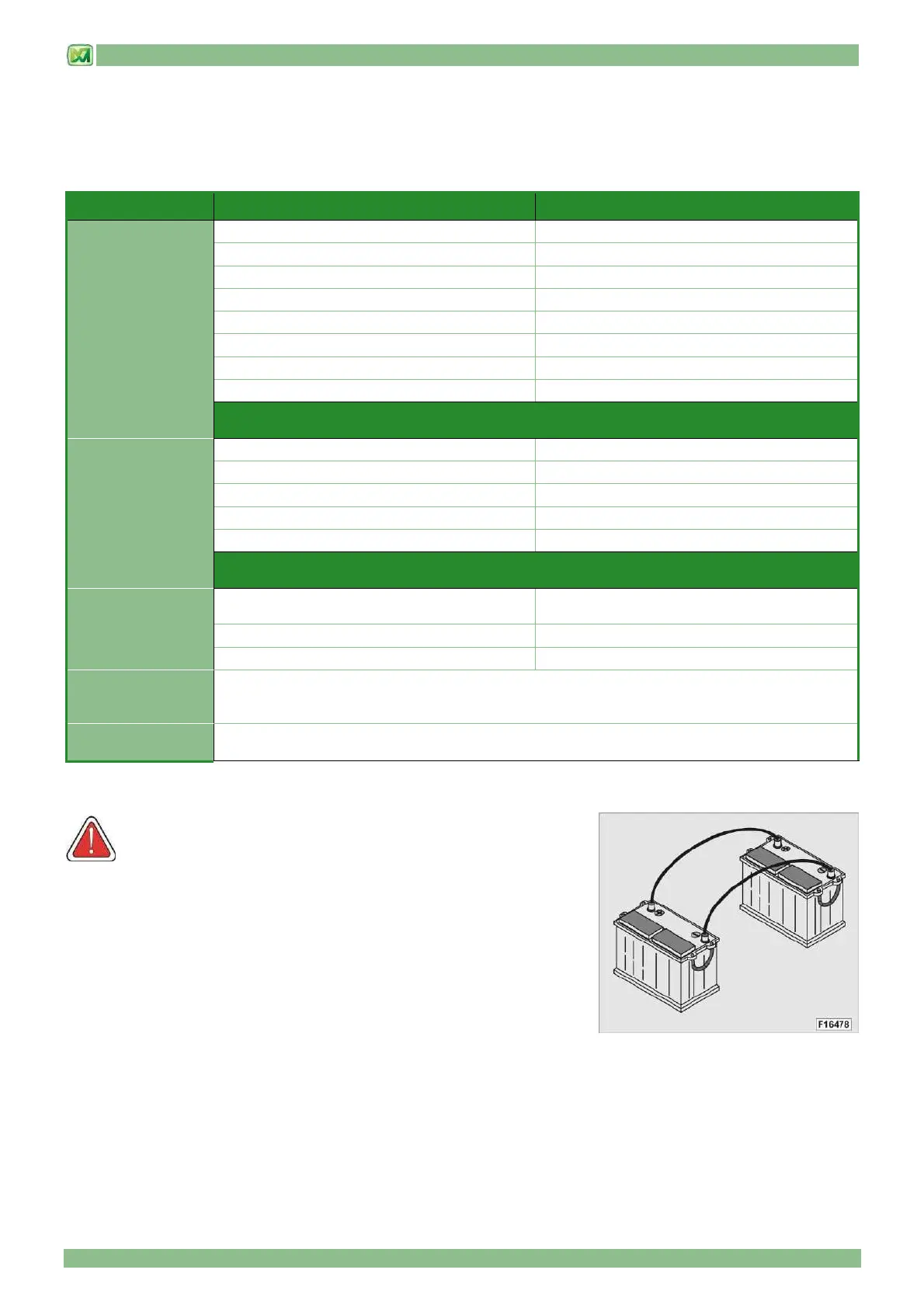

• STARTING THE ENGINE WITH FLAT BATTERY

WARNING! Before working on the battery, carefully read the

instructions found in paragraph "BATTERY" and in chapter "ELECTRICAL

SYSTEM". Check polarity before connecting the cables. Avoid any contact

between the two cables.

If the battery is flat, the engine can be started as follows:

1) Take an emergency battery having the same characteristics and two cables.

2) Connect the cable to the (+) and (-) of the battery inside the machine and,

then, to the correspondent (+) and (-) of the emergency battery.

3) Start the engine and disconnect the cables.

Loading...

Loading...