4 - COMMANDS AND INSTRUMENTS

4 - 28

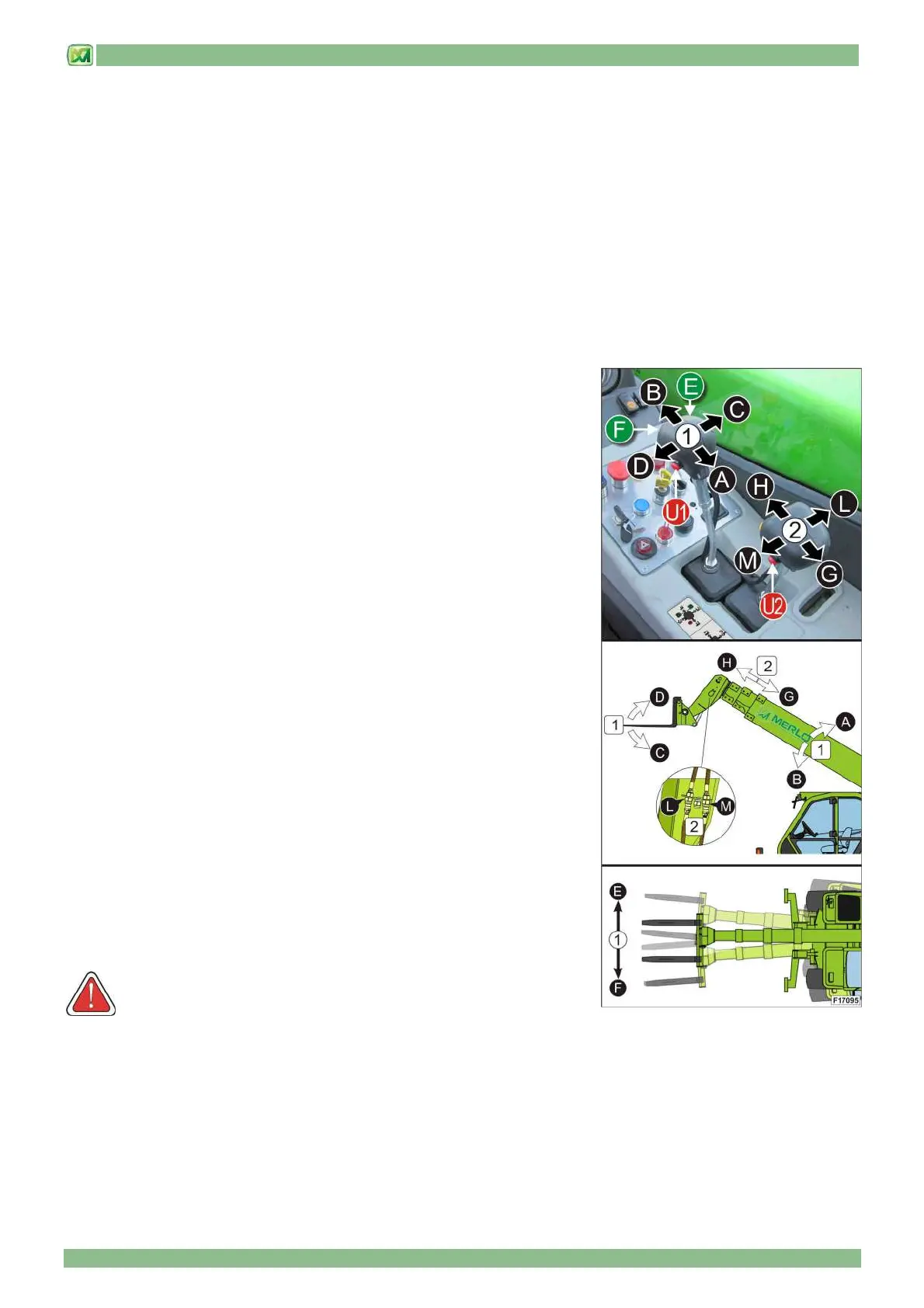

MAIN DISTRIBUTOR LEVER (1-2)

(only for models P38.12 – P38.13 – P38.14 – P40.17 – P38.13EE – P40.17EE)

These machines are equipped with two control levers with which it is possible to perform the following movements:

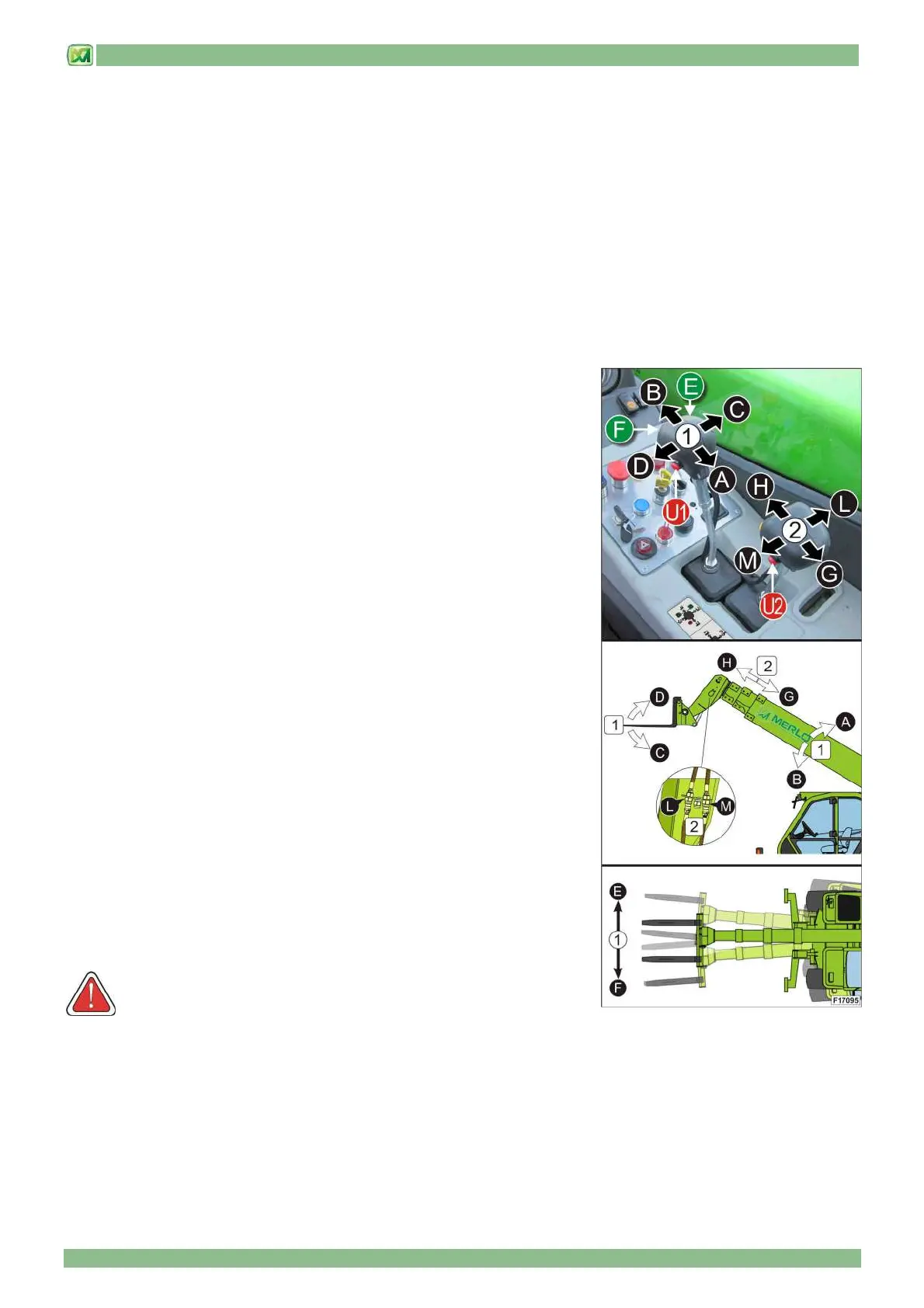

1) LIFTING/LOWER OF THE TELESCOPIC BOOM

2) UPWARD/DOWNWARD ROTATION OF THE FORKS

3) EXTENSION/RETRACTION OF THE TELESCOPIC BOOM

4) LEFT/RIGHT SIDE SHIFT

5) COMMAND FOR ATTACHMENTS INSTALLED ON THE CARRIAGE

The speed of the movement to be made is proportional to:

- the inclination given to the control lever (the greater the movement of the lever, the greater the speed of the movement)

- the rpm of the diesel engine (the higher the rpm of the engine, the greater the speed of movement).

The movement stops automatically when the lever used is released. Depending

on load conditions, it is possible to combine movements.

This machine is equipped with a side-shift that works directly on the base

chassis.

When the chassis of the machine is not in a central position, the system will

signal it with the lighting of the indicator light (56) on the instrument panel (C)

(see Chapter NOMENCLATURE).

Before driving on a public road, the chassis of the machine must be positioned

centrally (indicator light 56 off).

• CONTROL LEVERS ENABLING BUTTONS (U1) AND (U2)

U1 = Press and hold the button (U1) to enable the controls of the lever (1)

U2 = Press and hold the button (U2) to enable the controls of the lever (2)

• LEVER (1) IN POSITION:

A = boom lifting

B = boom descent

C = tilting of forks downward

D = tilting of forks upward

E = right side-shift

F = left side-shift

• LEVER (2) IN POSITION:

G = retraction of the telescopic boom

H = extension of the telescopic boom

L = attachments release/attachments command

M = attachments command

To move the machine, press and hold down the dedicated button. The movement

execution speed is set with a proportional ramp and reaches maximum speed

within about 4 seconds of pressing the control. To make small movements, press

the control switches briefly.

WARNING! Before operating the machine, please mark off the area

where the machine needs to be operated, in order to keep both people and vehicles away from it.

Should you need to operate the machine near overhead lines, the person in charge of safety shall require the

minimum safety distance from such lines to the manager of said lines, as well as from the authorities in charge of

safety and health in the workplace; in this way all necessary precautions shall be taken and potential accidents shall

be prevented. For further information please refer to paragraph "INSTRUCTIONS FOR A CORRECT USE OF THE

MACHINE NEAR OVERHEAD LINES" in chapter "OPERATING INSTRUCTIONS".

Loading...

Loading...