6 - ORDINARY MAINTENANCE

6 - 25

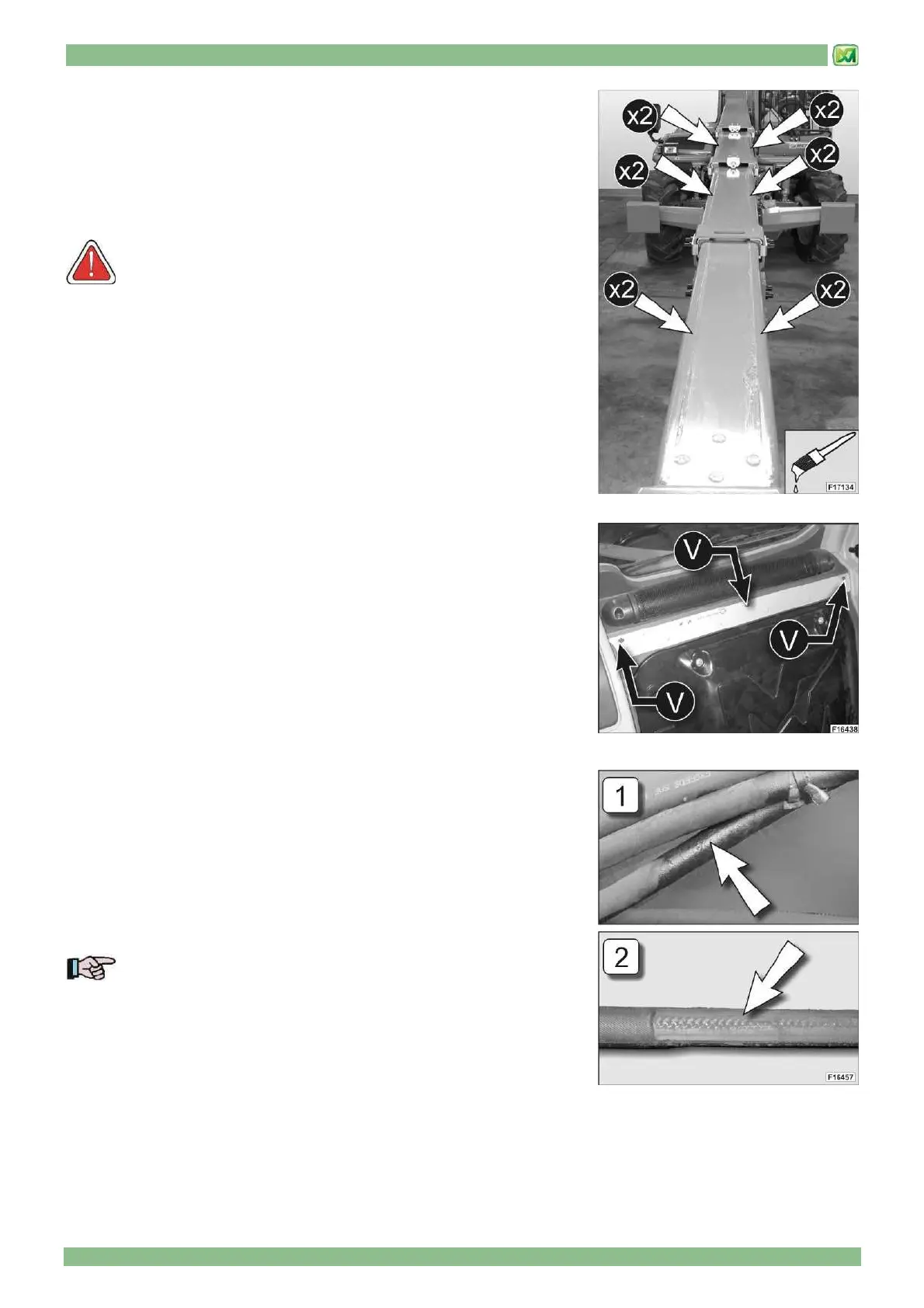

• BOOM SLIDING PADS (EXTERNAL)

- Fully extend the telescopic boom

- Carefully clean the boom sliding surface, removing the residual grease

- Using a cotton wad, evenly spread a thin layer of grease (see paragraph

"FUELS AND LUBRICANTS") over the entire boom sliding surface

- Carry out a few boom extension and retraction cycles so as to evenly

distribute the product.

WARNING!

Only the recommended product can be used; a different product could

cause serious damages to the sliding surface of the boom. More frequent

greasing is required when using the machine in particularly demanding

conditions.

By way of example only, the boom of a P40.17 PLUS machine (3

extensions) is shown. Perform the same operations for the telescopic

boom on your machine (1 or 2 extensions depending on the model).

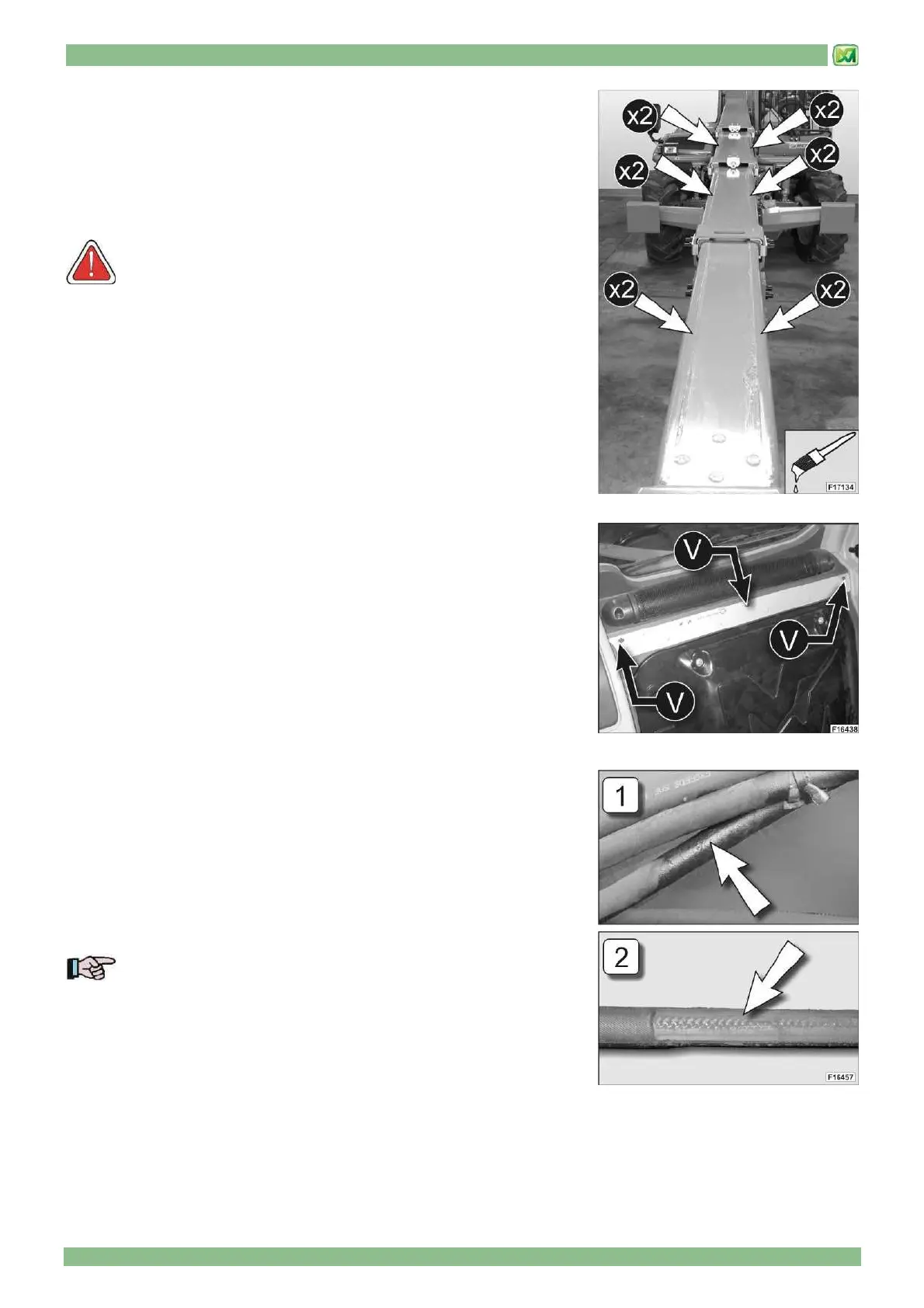

• AIR VENTILATION FILTER

Replace the filter of the cab ventilation system as follows:

- Unscrew fastening screws "V"

- Extract the cab ventilation filter

- Replace the filter with a new one with the same features

- refit the filter, tightening the fastening screws "V"

• HYDRAULIC HOSES

Perform the following checks on the hydraulic hoses:

1) visual check for any oil leaks

2) visual check for any marks on the hydraulic hoses which might be indicative of

future oil leaks (photo 1)

3) visual check for any mechanical scraping or grazing on the external protection of

the hydraulic hoses (photo 2)

Should any of the conditions above occur, replace the defective hose as soon as

possible, so as to prevent the problem from getting worse.

NOTE! Photos 1 and 2 show some examples of problems which might

occur on hydraulic hoses.

Loading...

Loading...