Technical Information

85

CVA 265x & CVA 266x

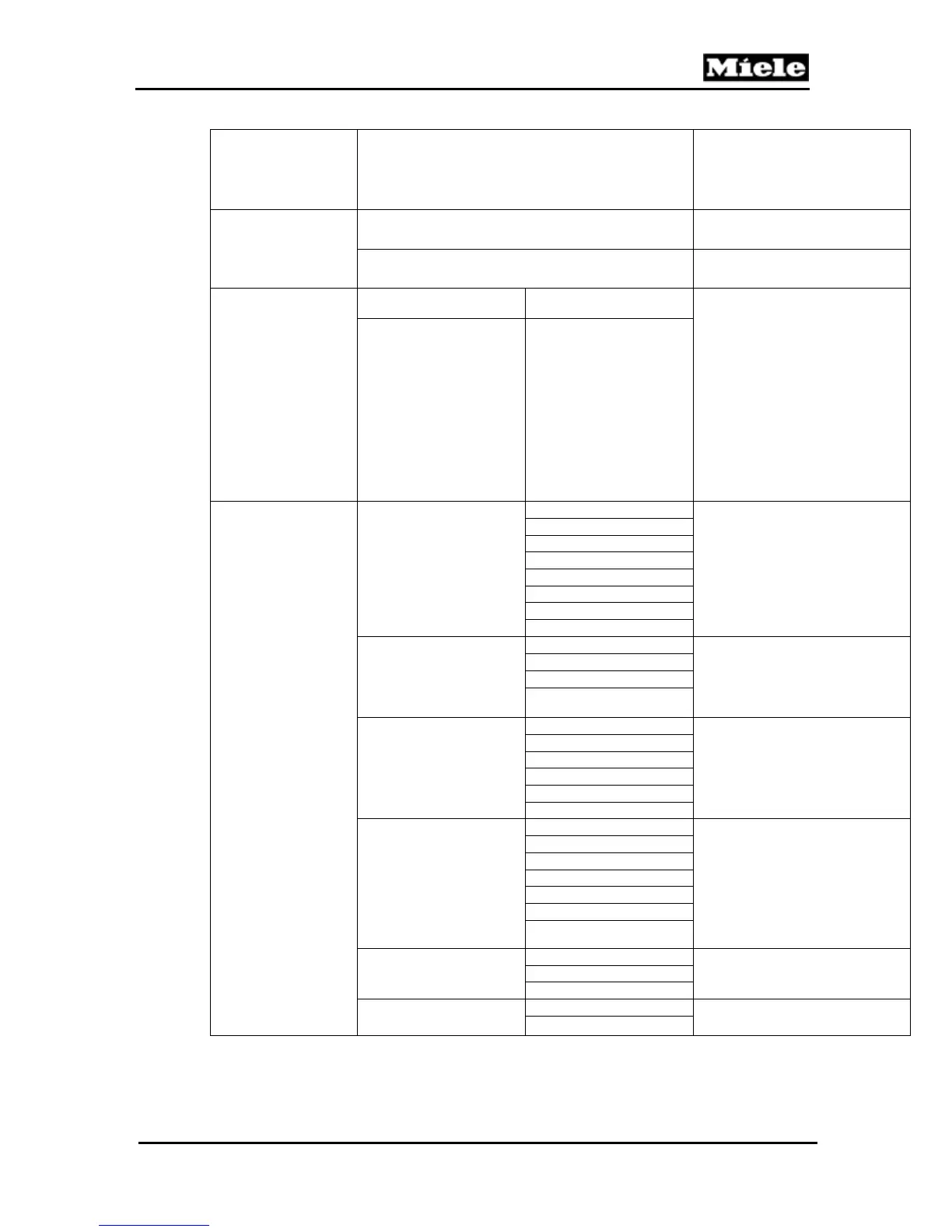

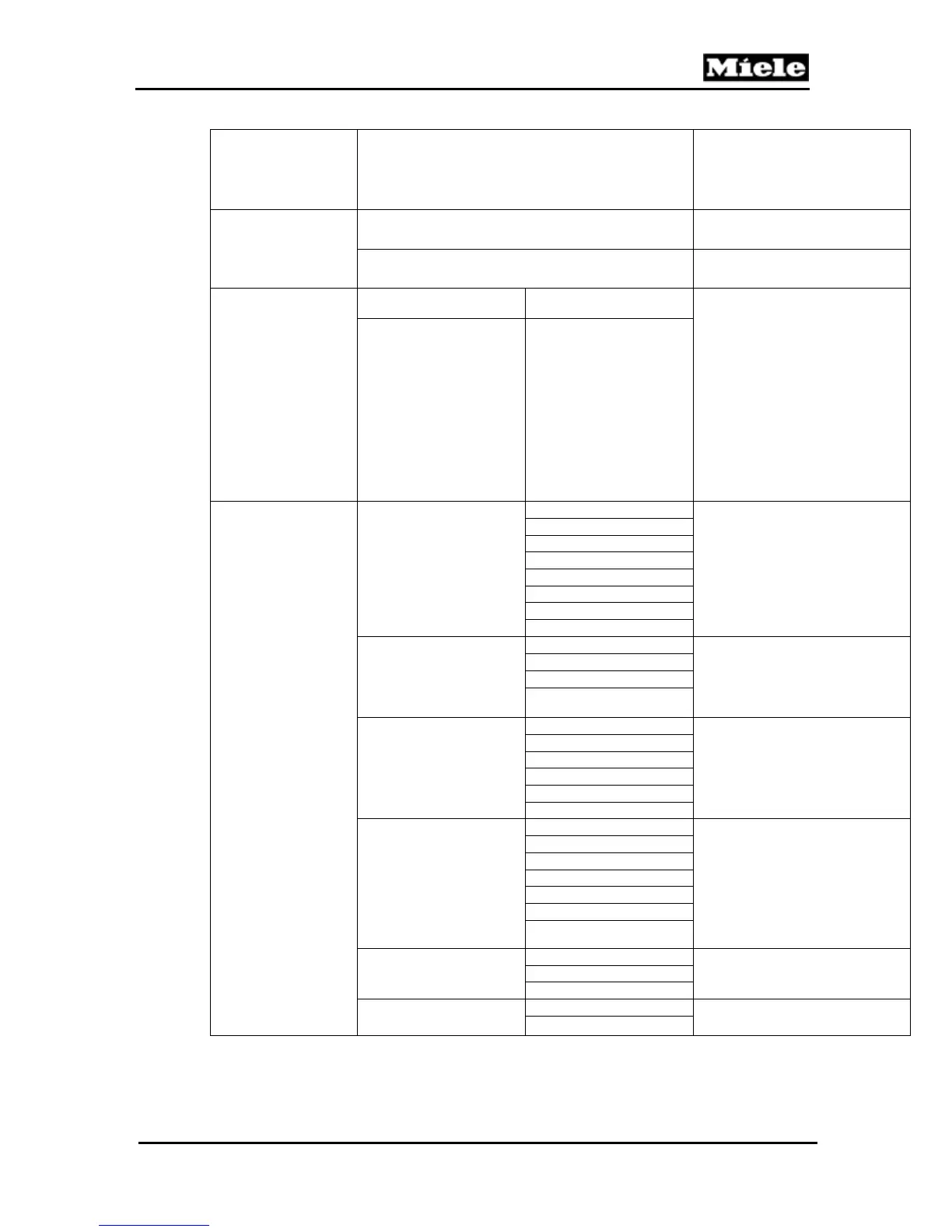

Function Option/Component Activated Description

Program index

ID no. 1:

ID no. of display and EPWZ 850

control electronic

ID no. 2:

ID no. of EPL 850 power

electronic

Fault

memory

1

Page 1 Faults 1 - 6

The last 12 fault codes

registered are shown.

The last fault code is marked

with L. If a fault is registered

more than once, its code will be

shown the appropriate number

of times unless the faults

occurred immediately after each

other.

See Table 060-2 for fault code

descriptions.

Page 2 Faults 7 - 12

Component test

Ceramic valve

2

Initialize

Valve reference and

valve position sensors display 0

and 1 alternately.

Step counterclockwise

Step clockwise

Rest position

Coffee position

Water position

Cont. counterclockwise

Continuous clockwise

Capsule transport

2

Initialize Slide sensor reading:

0 = Capsule transport lever in

intermediate setting

1 = Capsule transport lever in

basic setting

Carry out

Service position

Continuous operation

Capsule magazine

2

Initialize

Capsule magazine check

(Table 060-9)

Step counterclockwise

Step clockwise

Chamber 1 to 5

Cont. counterclockwise

Continuous clockwise

Brew unit

2

Initialize To reach the lowered end

position, the capsule plate must

be removed from the brew unit

beforehand.

The press position can only be

reached with the capsule plate

installed.

(See also Table 060-10.)

Rest position

Eject position

Press position

Service position

Continuous upwards

Continuous downwards

Coffee/hot-water pump

Release

The display shows the number

of pulses registered by the flow

meter. See Table 060-11.

Brew unit

Cappuccinatore

Steam pump

Release

Steam pump check

Cappuccinatore

Loading...

Loading...