5Functions set with parameters

Warm-Up Operation Mode 5-394

*Methods to Check the Warm-Up Operation Status

Whether the current status is the warm-up operation status or normal status can be checked in the following

three methods:

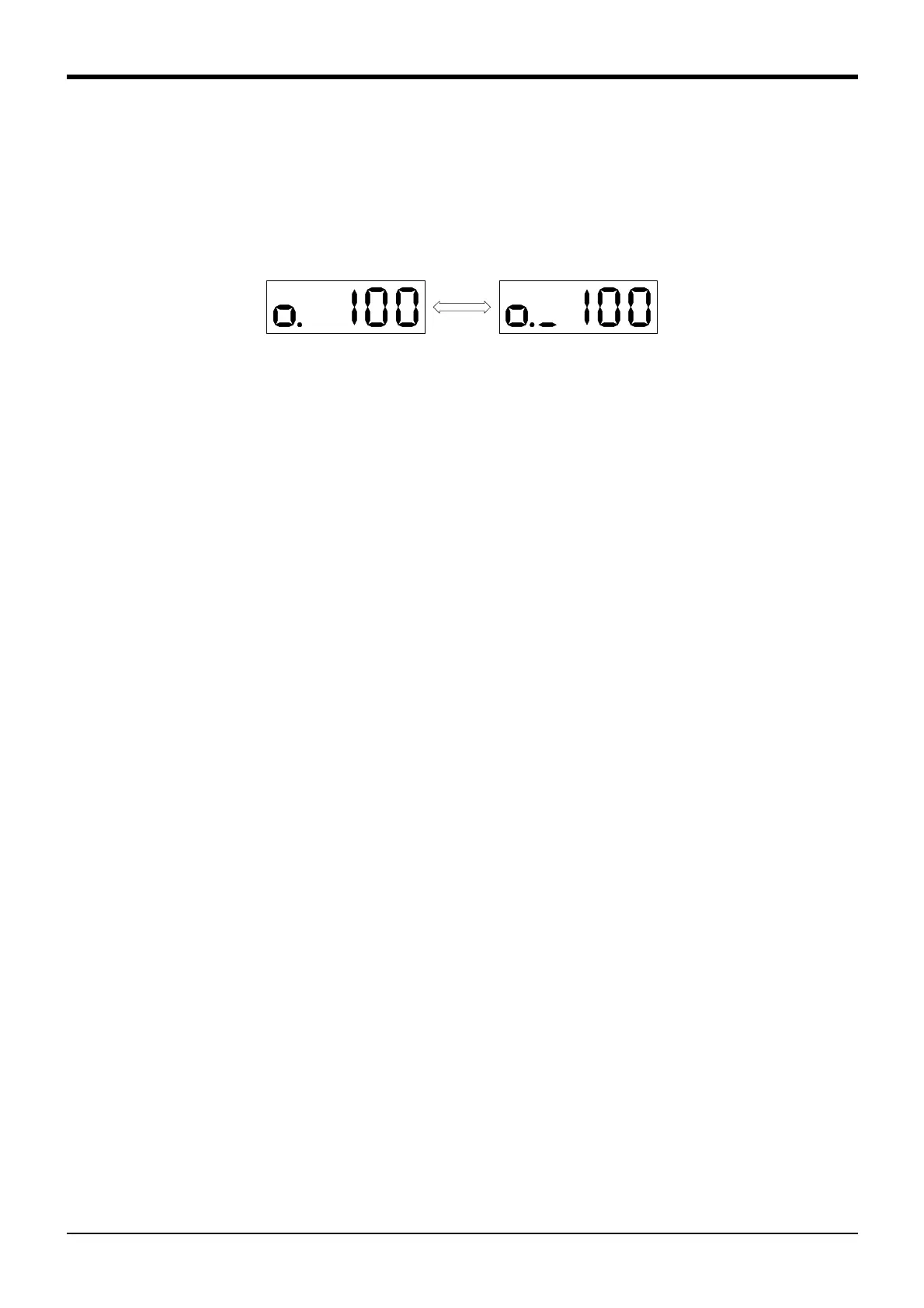

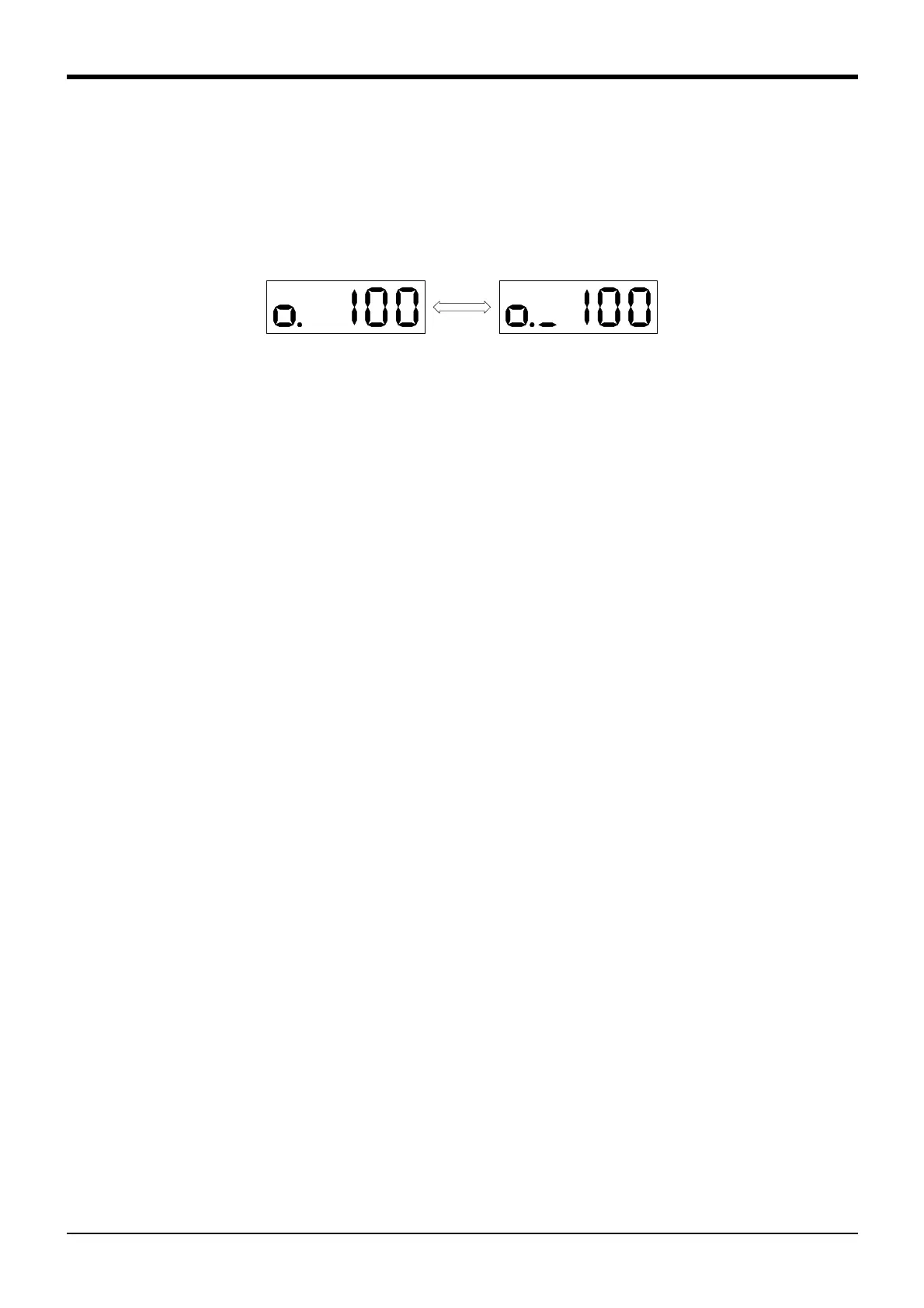

• Checking with STATUS NUMBER on the controller's front panel

The current status can be checked by setting STATUS NUMBER to override display. In the warm-up oper-

ation status, an underscore (_) is displayed in the second digit from the left.

Fig.5-5:Override Display in the Warm-Up Operation Status

• Checking with a status variable

The current status can be checked by monitoring the value of the M_Wupov status variable (the value of a

warm-up operation override). In the normal status, the value of M_Wupov is set to 100%; in the warm-up

operation status, it is below 100%.

• Checking with a dedicated output signal

In the warm-up operation status, the MnWUPMD (n = 1 to 3: mechanism number) dedicated output signal is

output.

*Switching Between the Normal Status and the Warm-Up Operation Status

When in the warm-up operation status, if a target axis in the warm-up operation mode continues operating

and its operation time exceeds the valid time of the warm-up operation status, the warm-up operation status

is canceled and the normal status is set. Thereafter, if the robot continues to stop, the joint section is cooled

down in a low temperature environment. When a target axis continues to stop over an extended period of

time and the resume time of the warm-up operation status is exceeded, the normal status switches to the

warm-up operation status again.

• Canceling the warm-up operation status

If the accumulated time a target axis has operated exceeds the valid time of the warm-up operation status,

the warm-up operation status is canceled and the normal status is set. Specify the valid time of the warm-up

operation status in the first element of the WUPTIME parameter. (The setting value at shipment from the

factory is 1 min.) If a multiple number of target axes exist, the warm-up operation status is canceled when all

target axes exceed the valid time. Note that, with the M_Wuprt status variable, you can check when the

warm-up operation status will be canceled after how much more time a target axis operates.

• Switching from the normal status to the warning-up operation status

If the time during which a target axis continues to stop exceeds the resume time of the warm-up operation

status, the normal status switches to the warm-up operation status. Specify the resume time of the warm-up

operation status in the second element of the WUPTIME parameter. (The setting value at shipment from the

factory is 60 min.)

If a multiple number of target axes exist, the warm-up operation status is set when at least one of the axes

exceeds the resume time of the warm-up operation status.

Note that, with the M_Wupst status variable, you can check when the status is switched to the warm-up

operation status after how much more time a target axis continues to stop.

Note: If a target axis is not operating even when the robot is operating, it is determined that the target axis is

stopping.

Normal Status Warm-Up Operation Status

Loading...

Loading...