4MELFA-BASIC IV

Detailed specifications of MELFA-BASIC V 4-140

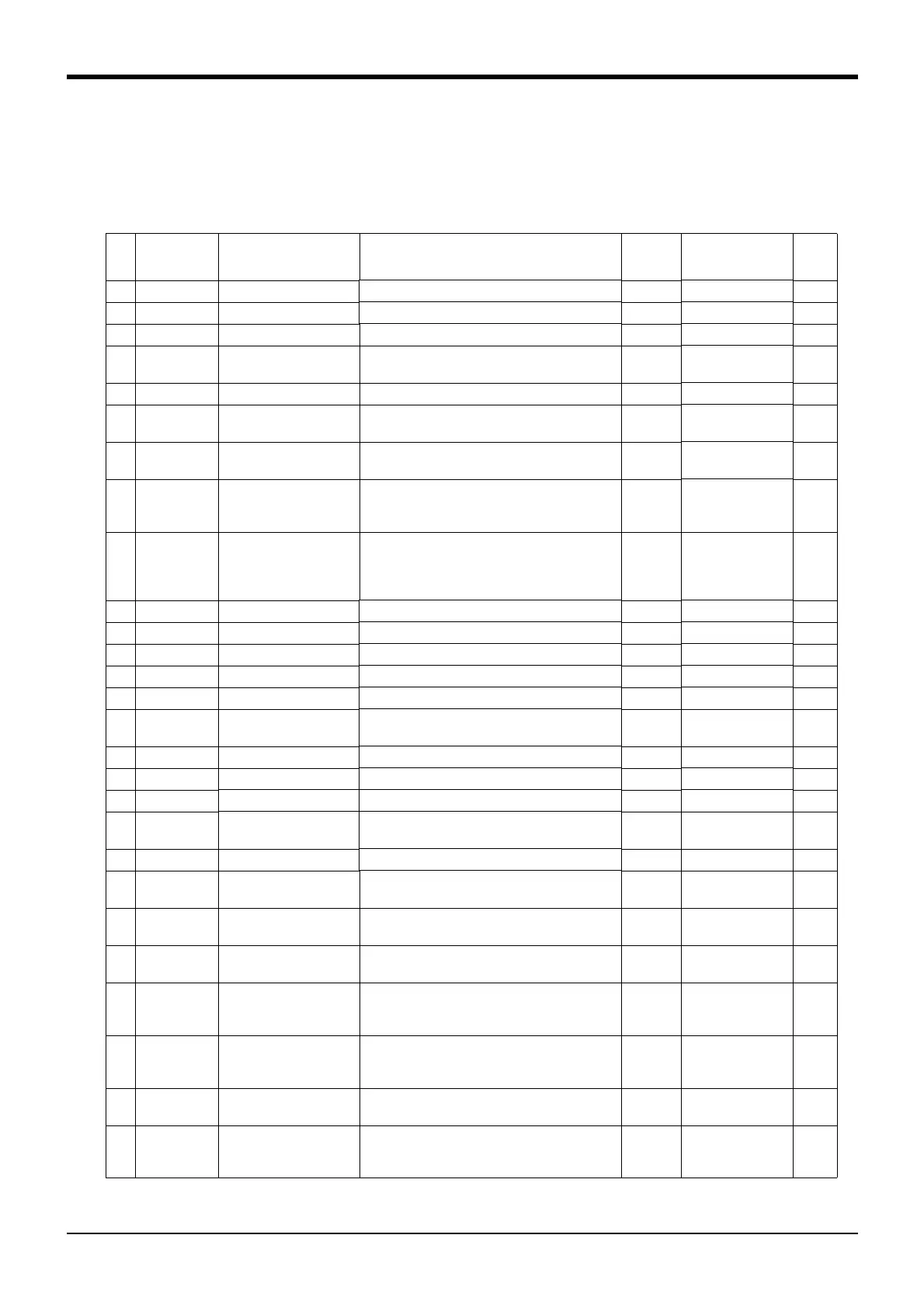

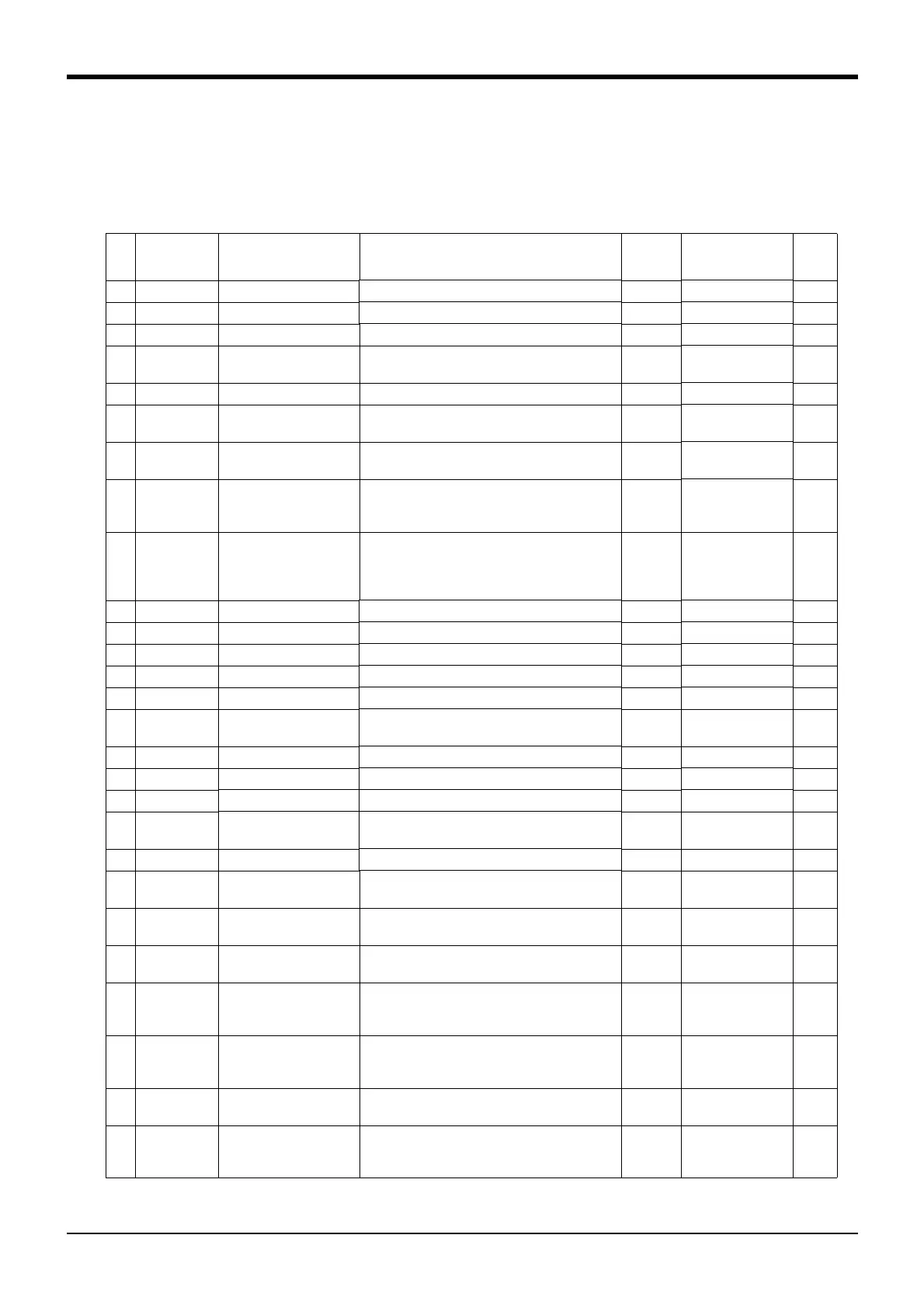

4.3.26 Robot status variables

The available robot status variables are shown in Table 4-8. As shown in the table, the variable name and

application are predetermined.

The robot status can be checked and changed by using these variables.

Table 4-8:Robot status variables

No

Variable

name

Array designation

Note1)

Details

Attribute

Note2)

Data type, Unit Page

1 P_Curr Mechanism No.(1 to 3)

Current position (XYZ) R Position type 304

2 J_Curr Mechanism No.(1 to 3)

Current position (joint) R Joint type 268

3 J_ECurr Mechanism No.(1 to 3)

Current encoder pulse position R Joint type 270

4 J_Fbc Mechanism No.(1 to 3)

Joint position generated based on the feedback

value from the servo

R Joint type 271

5 J_AmpFbc Mechanism No.(1 to 3)

Current feedback value R Joint type 271

6 P_Fbc Mechanism No.(1 to 3)

XYZ position generated based on the feedback

value from the servo

R Position type 305

7 M_Fbd Mechanism No.(1 to 3)

Distance between commanded position and

feedback position

R Position type 280

8 M_CmpDst Mechanism No.(1 to 3)

Amount of difference between a command value

and the actual position when the compliance

function is being performed

R Single-precision

real number type,

mm

274

9 M_CmpLmt Mechanism No.(1 to 3)

This is used to recover from the error status by

using interrupt processing when an error has

occurred while the command value in the

compliance mode attempted to exceed the limit.

R Integer type 275

10 P_Tool Mechanism No.(1 to 3)

Currently designated tool conversion data R Position type 306

11 P_Base Mechanism No.(1 to 3)

Currently designated base conversion data R Position type 302

12 P_NTool Mechanism No.(1 to 3)

System default value (tool conversion data) R Position type 306

13 P_NBase Mechanism No.(1 to 3)

System default value (base conversion data) R Position type 302

14 M_Tool Mechanism No.(1 to 3)

Tool No. (1 to 4) RW Integer type 295

15 J_ColMxl Mechanism No.(1 to 3)

Difference between estimated torque and actual

torque

R Joint type, % 269

16 M_ColSts Mechanism No.(1 to 3)

Impact detection status (1: Colliding, 0: Others) R Integer type 276

17 P_ColDir Mechanism No.(1 to 3)

Movement direction at collision R Position type 303

18 M_OPovrd None

Speed override on the operation panel (0 to 100%) R Integer type, % 283

19 M_Ovrd Slot No.(1to 32)

Override in currently designated program (0 to

100%)

R Integer type, % 283

20 M_JOvrd Slot No.(1to 32)

Currently designated joint override (0 to 100%) R Integer type, % 283

21 M_NOvrd Slot No.(1to 32)

System default value (default value of M_Ovrd)

(%)

R Single-precision

real number type, %

283

22 M_NJovrd Slot No.(1to 32)

System default value (default value of M_JOvrd)

(%)

R Single-precision

real number type, %

283

23 M_Wupov Mechanism No.(1 to 3)

Warm-up operation override (50 to 100%) R Single-precision

real number type, %

299

24 M_Wuprt Mechanism No.(1 to 3)

Time until the warm-up operation status is

canceled (sec.)

R Single-precision

real number type,

sec

300

25 M_Wupst Mechanism No.(1 to 3)

Time until the warm-up operation status is set

again (sec.)

R Single-precision

real number type,

sec

301

26 M_Ratio Slot No.(1to 32)

Fraction of the current movement left before

reaching the target position (%)

R Integer type, % 289

27 M_RDst Slot No.(1to 32)

Remaining distance left of the current movement

(only the three dimensions of X, Y, and Z are taken

into consideration: mm)

R Single-precision

real number type,

mm

290

Loading...

Loading...