MSDServoDrive AC-AC Operation Manual

moog

30

Id. no.:CA65642-001 Date:03/2012

to the glossaryto the table of contents

3.7.3 Use with mains choke

The use of mains chokes is:

• necessary with all device from and including size Size5

• necessary when using servo drives in hostile industrial networks

• recommended to prolong the lifetime of DC link capacitors

3.7.4 Use with internal mains filter

Servo drives Size1 to Size5 are equipped with integrated mains filters. With the

measuring methods specified in the standard these servo drives comply with the EMC

safety-related requirements specified in IEC 61800-3 for ”Environment 1“ (residential

area C2) and “Environment 2“ (industrial area C3). More detailed information see

sectionA.6 „Mains filter“, page70.

ATTENTION! This is a restricted availability product in accordance with IEC

61800-3. In living areas this product may cause radio interference; in this case

the operator may be forced to apply appropriate measures.

3.7.5 Use with external mains filter

External radio interference suppression filters (CA71188-001 to CA71190-001,

CB09932-001) are available for the servo drives for Size6 and Size6A. With the

specified measuring method and the external mains filter these servo drives also ensure

compliance with the EMC product standard EN 61800-3 für “Environment 1” (residential

areas C2) and “Environment 2” (industrial area C3).

The question of whether size Size7 requires an external mains filter depends on the type

of connection and the local conditions. For this reason the use of a mains filter must

always considered individually and within the scope of a project.

In order to reach the use of longer motor cables and compliance with the EMC product

standard IEC 61800-3 for the “general availability” (residential area C1), additional

external mains filters are available for the devices with internal mains filters (Size1 to

Size5).

!

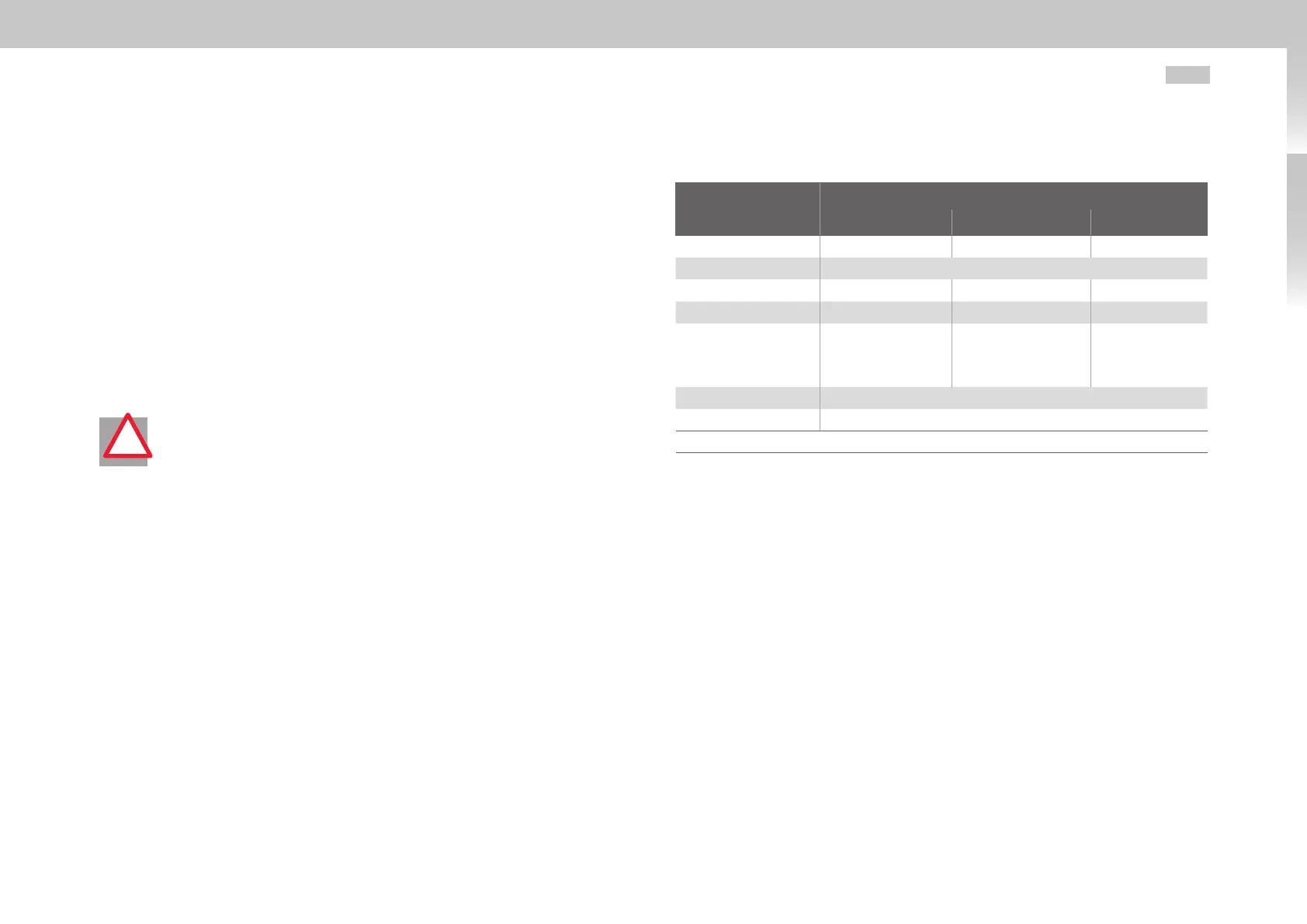

3.7.6 Terminal diagram precharge (only Size7)

Designation

Specification

G395-250 G395-325 G395-450

Fuses1

250A 315A

400A

Fuses2, slow-blowing

6A

Mains filter (optional)

220A 300A

400A

Mains choke (U

k

=2%)

250A 325A

450A

K1

225A/ 110kW / 230V

(e.g. Siemens 3RT10

64-6AP36)

300A / 160kW / 230V

(e.g. Siemens 3RT10

66-6AP36)

400A / 200kW

/ 230V (e.g.

Siemens 3RT10

75-6AP36)

K2

12A / 5.5kW / 24V (e.g. Siemens 3RT10 17-1AB01)

K3

7A / 3kW / 24V (e.g. Siemens 3RT10 15-1AB01)

Recommended data for operation with asynchronous machine

Table 3.8 Specification of connection periphery

Wire the precharge circuitry as shown in Fig.3.14 as per standard with short-circuit

proof cables. The connected loads of the internal relay for terminals X44/3, 4 are

U

max

= 30VDC, I

max

= 6A. You should therefore use a contactor relay K3.

Control sequence

• Precharge of DC link

Switch S1 “Mains supply On” is switched on. The precharging contactor K2 closes and

the DC link is precharged via internal precharging resistor on terminal X45. The main

contactor K1 remains open for the time being.

• Precharging completed

At a defined DC link voltage the contact of the internal relay on terminal X44/3.4

is closed. The contactor relay K3 closes and connects the main contactor K1. The

precharging contactor K2 is opened via an auxiliary contact (normally closed contact)

on K1. The MSDServoDriveAC-AC changes to standby.

• Switching off

The switch S1 “Mains supply Off” completely disconnects the servo drive from the

mains supply.

Loading...

Loading...